Principles of safe operation of bale wrapper

Bale wrapper must be operated by adult with driving licence to the steering of agricultural tractors, having

knowledge of HEALTH and SAFETY at WORK in the use of agricultural equipment;

During installation, adjustment and repairs of bale wrapper, turn off the tractor engine and remove the keys

from the ignition, during these steps the bale wrapper should be lowered to the ground and tractor should be

stationary

;

Before switching on the rotary drive, make sure that switching on the drive does not threaten anyone;

Staying of persons in work zone of bale wrapper and loader is prohibited;

Before starting work, check the condition of the machine and its completeness;

Work with machine damaged or without protective covers is prohibited;

Before starting work, check the condition of the hydraulic hoses/lines, work with broken or deformed lines/

hoses is prohibited;

Transport of bales on bale wrapper when traveling on public roads is prohibited;

When

loading

bales

one

should

pay

special

a en on

on

permissible

load

capacity

of

loading

equipment.

Exceeding

the

load

capacity

may

cause

damage

to

machine

and

accident.

Summary of Contents for EW-450A

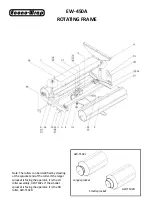

Page 1: ...Operator s Manual Rev 05 22 Stationary Bale Wrapper EW 450A...

Page 13: ...Parts Breakdown...

Page 16: ...EW 450A LOWER FRAME...

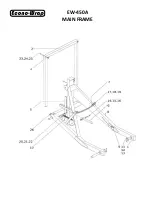

Page 18: ...EW 450A MAIN FRAME...

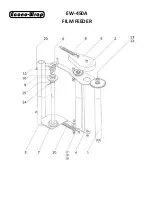

Page 20: ...EW 450A FILM FEEDER...

Page 22: ......