A.4 Testing surfaces.

A.4.1 MicrobMonitor2

can be used to test for microbial contamination on surfaces, e.g. to test deposits on tank surfaces or

filters. Sterile swabs (available separately) should be used to remove surface contamination and transfer this to a

MicrobMonitor2

test bottle.

A.4.2 Open the peel pack containing a swab at the handle end and remove the swab, taking care not to touch the

cotton end of the swab and the handle near the cotton end.

A.4.3 Rub the surface to be tested using the cotton end of the swab, rotating the swab handle so that all parts of the

cotton end contact the surface. If possible swab a known area of surface.

A.4.4 Insert the cotton end of the swab into the neck of the MicrobMonitor2

test bottle and stab it into the gel and agitate

for about 15 seconds and then remove and discard.

A.4.5 Replace the cap on the MicrobMonitor2

bottle and tighten. Record the sample details and test date on the label

provided and stick it on a narrow side of the bottle. Proceed to step B.

7

6

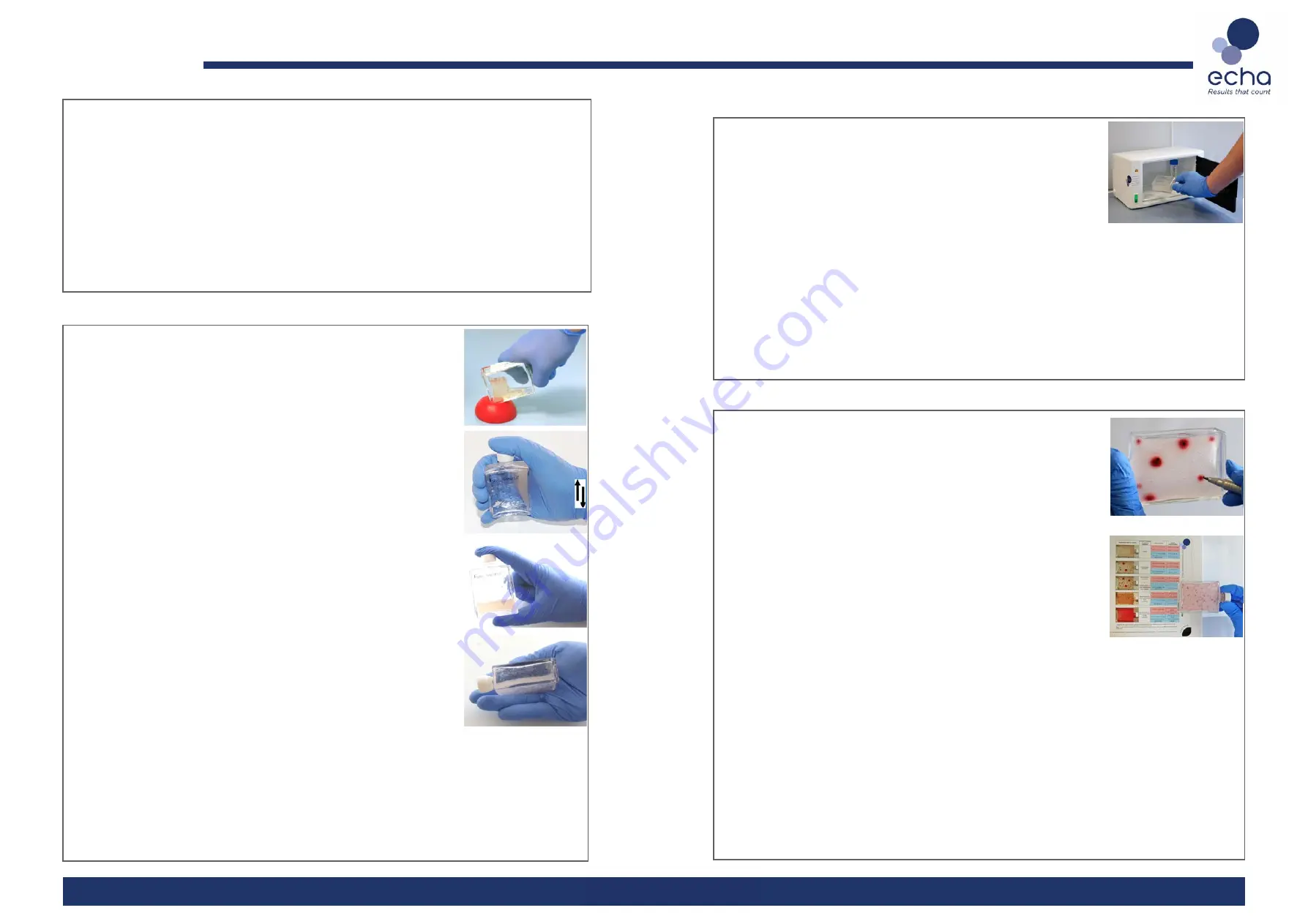

B.1 Loosen and break up the gel in the MicrobMonitor2

bottle containing the dispensed

sample, by tapping the bottle firmly in the palm of your hand or on a rubber bung or

MicrobMonitor “Bumper” (available separately).

B.2 Shake the bottle vigorously for approximately 30 seconds to liquefy the gel and

disperse the sample. The test bottle can be tapped repeatedly for 30 seconds on a

MicrobMonitor “Bumper” to assist with shaking. After shaking, the gel should be slightly

viscous but free of lumps and have a uniform consistency and clarity. The presence of

bubbles in the gel is normal and will not affect the test.

B.3 Stop shaking the test bottle abruptly so that the gel collects in the bottom of the

bottle. Proceed immediately to B4.

B.4 Tap the bottle in the palm of the hand until the gel forms a flat layer on one of

the larger flat sides. Ensure that a uniform layer reaching all corners is obtained.

Notes on transport of tests

It is preferable to conduct testing on-site to avoid errors due to changes in the microbial content of samples during transport. If there are

likely to be delays of more than 24 hours in transporting samples to a testing facility, these errors can be avoided by conducting the first

stages of the MicrobMonitor2

test procedure (up to and including step B) on-site at the sampling location and then returning the

MicrobMonitor2

test to the testing facility to complete the incubation (step C). The test bottle should be kept flat during transport, should

not be agitated excessively and should be returned to the testing facility within 4 days. See note on incubation of tests (step C)

concerning appropriate adjustment of the incubation time.

Alternatively, MicrobMonitor2 test bottles can be transported to the test facility after sample has been added (step A) before shaking; the

test can then be shaken (step B) at the test facility. Incubation (step C) should be commenced within 6 hours of the sample being added

to the test bottle (or within 2 days if tests are kept cool (2 to 8°C)). If tests are transported to a test facility before shaking, it is not necessary

to keep them flat during transport and moderate agitation will not affect the test result.

B

Shake to disperse sample in the

MICROBMONITOR

2

®

gel.

Transfer the MicrobMonitor2 test bottle to a warm, dark location or incubator to maintain a

nominal temperature of 25°C ± 3°C. In normal circumstances the gel should be incubated

for 4 days. Avoid exposure to light during incubation.

The gel will set firmly after a few hours. Keep the gel on the lower surface of the bottle and

avoid excessive agitation or prolonged tilting of the bottle during incubation, examination

and any transportation.

Notes on incubation of tests.

Occasional temperature fluctuations (e.g. overnight) below the specified temperature range should not affect the number of colonies

which develop and will not critically affect the test result, but microbial colonies may take longer to become visible and thus an extension of

the specified incubation time should be applied. If the temperature falls below the specified range during incubation, the incubation time

should be extended by a time equivalent to the total time the temperature is estimated to have fallen below the specified range. If the

incubation temperature falls below the specified range for a period or periods totaling 4 days or more, microbial contamination will be

underestimated and the result should be considered invalid. The temperature should not be allowed to drop below 4°C during incubation.

Incubation of the culture medium above the specified temperature range may prejudice the ability to detect some types of microorganism.

However, where microbial contamination occurs in tanks or systems where the contents have a higher temperature than 25°C, the

contaminating microorganisms will often have a preference for growth at higher temperatures; in such cases it may be appropriate to

incubate the test at a temperature similar to the system sampled.

When using MicrobMonitor2 to test for compliance with a specific industry standard (e.g. the IATA Contamination Limits shown in table 2 on

page 8), if the test result indicates contamination is in the highest category (e.g. Heavy) before 4 days, it is generally acceptable to read

and report the result without further incubation.

C Incubate

the

MICROBMONITOR

2

®

test.

D Examine

the

MICROBMONITOR

2

®

test.

D.1 If possible examine the test daily during incubation. As a minimum, examine it on at

least one occasion in the first 3 days and again on the final day of incubation. To examine

the test, hold it against a light background and count the number of all visible purple

colonies. A hand magnifying lens may help you to identify and count small colonies. All

purple colonies in all parts of the test bottle should be counted, including any which are in

gel which is not part of the flat layer. Once a colony is counted do not count it again

even if it grows larger; it is the number of colonies that is important, not their size. It is

recommended that colonies are marked with a marker pen on the bottle to ensure that

they are not counted twice. Ignore any air bubbles which may form in the gel.

Notes on examining tests

Colonies are usually circular but may have irregular edges. Different types of microorganisms can grow at different rates in the gel culture

medium and therefore the colonies may be of different sizes. At the recommended incubation temperature, colonies of bacteria and

yeasts usually develop within 1 to 2 days and remain quite small. Moulds develop more slowly but eventually produce large colonies which

may have a powdery or "fuzzy" appearance. Generally, the more colonies there are in the test bottle, the smaller the colonies will be.

Ignore any microbial colonies which develop after the specified incubation period is complete (allowing for any extension applied due to

temperature falling below the specified range). The test may change appearance on prolonged incubation but this should be disregarded.

Colonies will tend to become visible more quickly in samples with a higher viable microbial content.

Occasionally, some antioxidant additives in fuels may interfere with the growth indicating compound in the test and produce a uniform light

peach or orange colour in the gel (usually within 12 hours). This colour change will not interfere with the growth of any microorganisms and

in most cases microbial colonies can be counted or estimated ignoring the background colour. In exceptional cases the interference may

be so strong that users may find it difficult to distinguish colour interference from an estimated count of 10,000 colonies. In such cases the

fuel should be retested using a smaller test volume (e.g. 0.01 ml) so that the interference effect is diluted out; if the original result was

genuinely due to heavy microbial contamination it would normally be expected that the retest will show a discernible number of red/purple

colonies and the background colour will be less intense.

Some bacteria can, on prolonged incubation, spread through the gel producing a large irregularly shaped colony, streak or patch of red or

purple colour in the gel. These bacteria usually grow quickly and thus if tests are examined while the colonies are still small (e.g. after 1 or 2

days incubation) they are more easily counted. The centre of each streak or patch should be counted as a single colony. Continue

incubation and count any new colonies which develop.

See technical leaflet EP157 Technical Assistance Reading Results of MicrobMonitor2 for further information on reading and interpreting tests

with unusual or atypical appearance.

D.2 It is usually possible to count up to about 250 colonies. If the number of colonies is too

numerous to count, visually compare the test to the Test Results Chart (see page 9)

holding the test against a white background. The chart provides an estimate of the

colony count.

MICROBMONITOR

2

®

T R U S T E D

I N N O V A T I V E

A C C U R A T E

D E P E N D A B L E

+

+

+

Results that count

Results that count