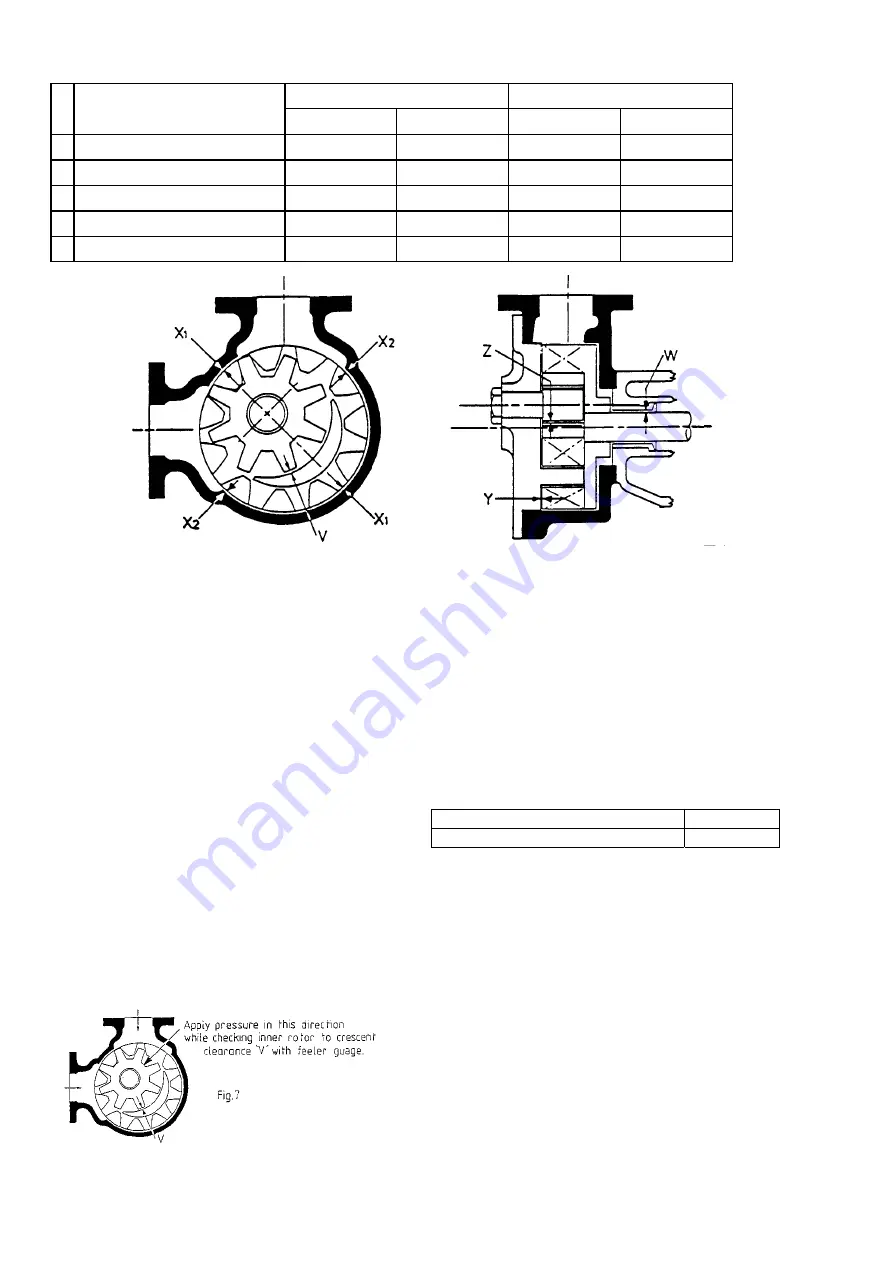

TABLE OF CLEARANCES

Metallic

Carbon

Running Clearances

'A'

CLEARANCE

'B'

CLEARANCE

'A'

CLEARANCE

'B'

CLEARANCE

Z

Diametral - Rotor Pin to Bearing

0.12-0.16 mm

0.12-0.16 mm

0.09-0.13mm

0.09-0.13mm

Y

Axial - Rotors to Cover

0.13-0.18 mm

0.17-0.22 mm

0.13-0.18 mm

0.17-0.22 mm

X

Diametral - Outer Rotor to Body

0.28-0.38 mm

0.40-0.53 mm

0.28-0.38 mm

0.40-0.53 mm

W Diametral - Shaft to Bearing

0.10-0.14 mm

0.13-0.16 mm

0.08-0.11mm

0.10-0.14mm

V

Radial - Inner Rotor to Crescent

0.03-0.08 mm

0.03-0.08 mm

0.02-0.06mm

0.02-0.06mm

Figure 6

6.

Carry out preliminary sizing checks:

a) Axial length of Inner Rotor, Outer Rotor teeth

and Cover crescent must be matched to within

+/- 0,02mm.

b) Outer Rotor in Body diametral clearance. Note:

If checking by feeler gauge method, allowance

or compensation must be made for eccentricity

caused by:

i) Weight of Rotor.

ii) Clearances between Shaft and Bracket

Bearing.

iii) Lack of Bearing support at drive end

6

To measure clearance, insert feeler gauge at

two opposite measurement points 'X

1

'. Add the

two clearances together. This will give the

diametral clearance 'X' for the two points.

Repeat this procedure for the other two

measurement points 'X

2

'.

c) To check clearance between Inner Rotor and

Cover crescent, Inner Rotor should be held

towards inlet plane. Refer Fig. 7

7.

Ensure all lubrication/cooling circulation

harness assemblies are clear of any

obstructions.

8.

EBSRAY recommend replacement of all

Gaskets, Seals and "O"rings at every overhaul,

to ensure positive sealing.

4.6

REASSEMBLY

(Refer Drg No. CMP051)

TORQUE SETTINGS

Cover to Body Studs and Nuts

203.4 Nm

Bracket to Body Setscrews:

203.4 Nm

During reassembly, lubrication is required in some

areas. All lubrication in areas where it may come into

contact with pumped product should be with a

product compatible lubricant. The Bracket Ball

Bearing and lockring Seals may be lubricated with

any high quality lithium base grease suitable for the

operating conditions.

1.

(For pumps fitted with SJ Cover Plate only)

Using a new Cover Gasket, locate the SJ Cover

Plate on the Cover with the Inner Rotor Pin bores in

alignment and temporarily fasten the two together

using bolts of the same diameter as the Cover

bolts. After fastening Inner Roror Pin (Step 4)

remove these temporary bolts.

2.

Fit Inner Rotor Pin Gasket to the Inner Rotor Pin

locating step.

Summary of Contents for HD600

Page 11: ...11 11 ...