Enterprise Power Solutions Installation and Operation Guide

38

Copyright © 2008 Eaton Corporation. All Rights Reserved.

IPN 997-00012-56C September 2008

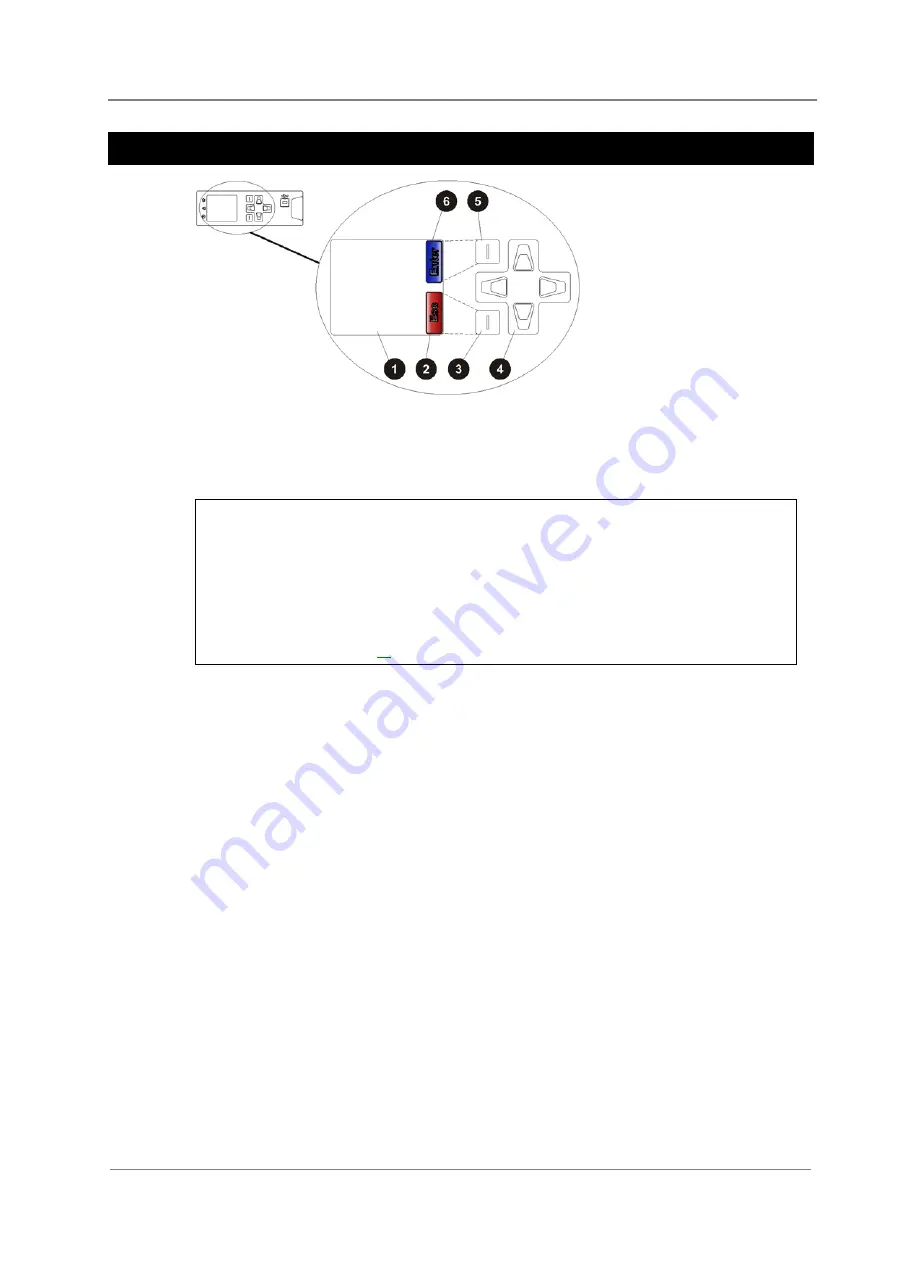

SC200 or SC100 Operation using the Keypad and Screen

"

LCD display

#

Soft key 1 label (SC200 only)

$

Soft key 1 (SC200 only)

%

Navigation keys (Up - Down -

Left - Right)

!

Soft key 2 (SC200 only)

&

Soft key 2 label (SC200 only)

Keypad Access Security

This feature prevents accidental or unauthorized changes to settings from the SC200 or

SC100 keypad.

All access to change an SC200's settings will be lost if:

•

All communications are disabled. See S3P Access and HTTP/HTTPS Access in

the System Controller Operation Handbook, and

•

Keypad access is PIN Protected, and

•

The keypad access PIN is lost.

The SC200 will continue to function, but no configuration changes can be made.

Contact your Powerware dc product supplier or Eaton for advice (see Worldwide

Support on page

►

To use DCTools/Web to enable/disable keypad access

•

In DCTools/Web go to

Communications

>

Front Panel

.

•

Set

Access

to:

•

Unprotected

- keypad access is allowed, or

•

Protected

- keypad access is denied (can be temporarily over-ridden, see below), or

•

PIN Protected (SC200 only)

- keypad access is allowed when a 4-digit number is

entered in the Access

PIN

field.

►

To temporarily enable keypad access when access is set to Protected

•

Press

Up

and

Down

keys together for approximately 10 seconds.

Keypad access is now temporarily enabled. Keypad access control reverts back to Protected

mode after return to the Summary Screen (or after the display time-out period).

►

To temporarily enable keypad access when access is set to PIN Protected (SC200

only)

•

Press

Up

and

Down

keys together for approximately 10 seconds.

•

Use the navigation keys to enter the correct 4-digit number.

Keypad access is now temporarily enabled. Keypad access control reverts back to PIN

Protected mode after return to the Summary Screen (or after the display time-out period).