INM831B Rev 4

1

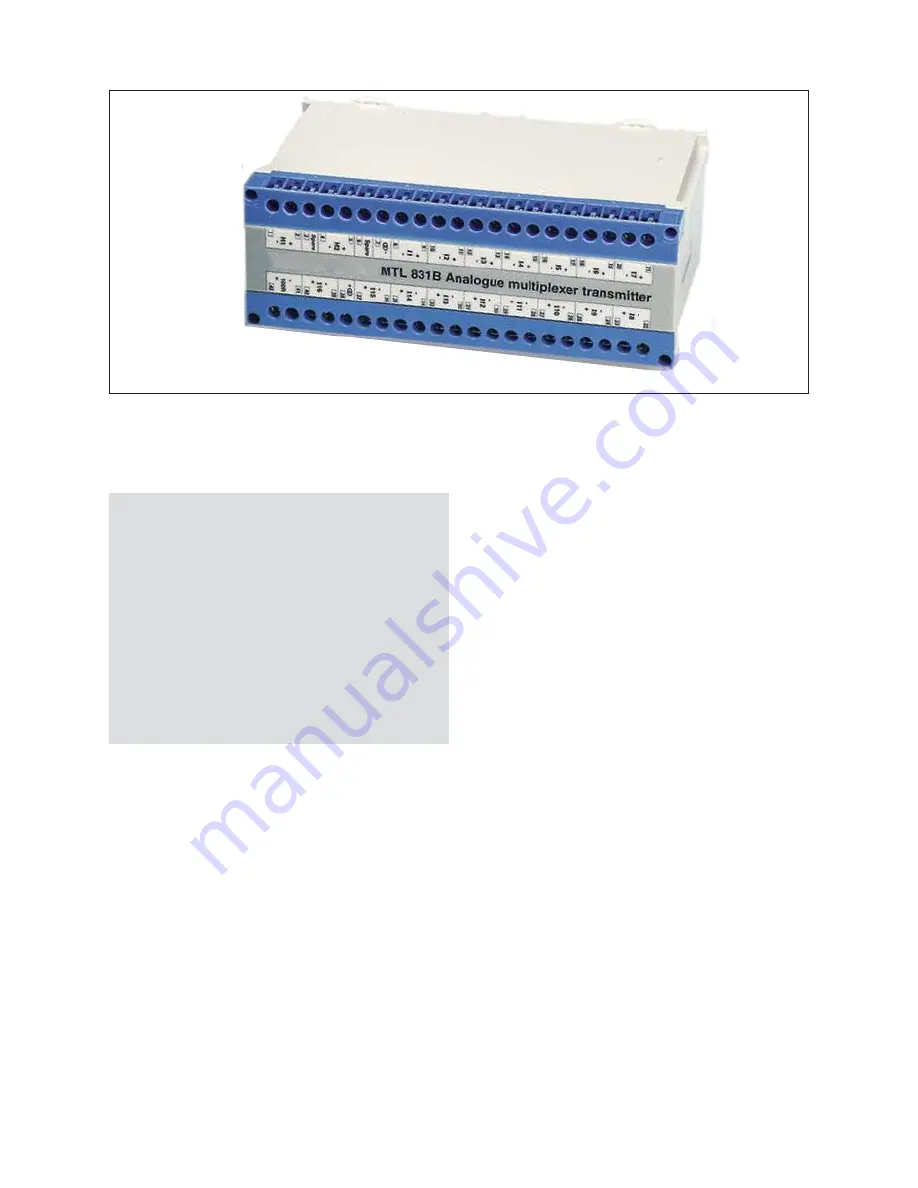

MTL831B

IS analogue multiplexer transmitter

INM831B Rev 3

1

ABOUT THIS MANUAL

The purpose of this manual is to provide the user with information on

the installation, connection and configuration of the MTL831B

analogue mutliplexer transmitter.

1.1

Related documents

This manual does NOT cover the connection or configuration of the

MTL838B-MBF receiver. For details of this item consult:

INM838B-MBF.

Additional application information is available in:

AN9010

.

1.2

Product description

The MTL831B analogue transmitter can transfer a number of

hazardous area input signals to the safe area down a data highway

consisting of a single twisted pair cable. It is intrinsically safe and can

therefore be mounted in Zone 0 hazardous areas or Class I, Division

1 hazardous locations.

The MTL831B can monitor up to 16 inputs from THC or millivolt

sources or up to 15 inputs from 2, 3 or 4-wire RTDs.

Two (i.e. dual redundant) data highway outputs are provided that can

carry both signal and power over distances up to 3km, depending on

the application, the cable and the (noise) environment - see Section

4.4. The highway cables can be simple twisted-wire pairs or pairs of

wire within an IS multi-core cable.

Modbus

®

is a registered trademark of Schneider Automation Inc.

At the other end of the data highway, MTL838B-MBF receivers are

used to translate the information transmitted from the MTL831B. The

MTL838B-MBF provides a Modbus

®

serial data output representation

of the inputs together with status information.

When the MTL831B transmitter is mounted in the hazardous area,

each data highway must be protected by an MTL3052 digital isolator

mounted in the safe area.

2

GETTING STARTED

Installation of the MTL831B multiplexer transmitter is divided into

three main topics.

Mechanical Installation

- how to mount the MTL831B and

how it may be fitted into our enclosure.

Electrical Connections

- the sensor and highway

connections. If units are installed in our enclosures, it details any

special wiring arrangements.

Configuration

- the address and input mode selection by the

setting of internal switches.

Note

: A new user might find it helpful to set up the system, or a

simple version of it, in an indoor test area to gain familiarisation

before undertaking installation on site.

3

MECHANICAL INSTALLATION

3.1

Location

The MTL831B can be installed in either safe or hazardous areas

(including Zone 0 or Division 1) depending upon the requirements of

the application.

3.2

Mounting options

The unit can be mounted on T-section DIN-rail or onto a flat surface.

Eaton has a range of enclosures - ENC8, ENC8-SS, ENC83 or

ENC83-SS - to provide suitable IP67 protection if the transmitter is

located in an exposed area.

3.2.1

Mounting on T-section DIN-rail (Figure 1)

Hook the side opposite the central mounting clip onto standard 35mm

DIN46277 T-section rail and push downwards until the unit clicks into

place.

To remove, ease the central clip below the base of the unit outwards

(with a screwdriver) and unhook the clips on the other side.

MTL831B transmitter and MTL838B-MBF reciever

"

Cautionary Note

: In common with all other electrical apparatus

installed in hazardous areas, this apparatus must only be installed,

operated and maintained by competent personnel. Such personnel

shall have undergone training, which included instruction on the

various types of protection and installation practices, the relevant

rules and regulations, and on the general principles of area

classification. Appropriate refresher training shall be given on a

regular basis. [See clause 4.2 of EN 60079-17].

This instruction manual supplements the requirements of nationally

accepted codes of practice, for example, IEC/EN 60079-14 in

Europe and the National Electrical Code, combined with

ANSI/ISA-RP 12.12 in the USA. All installations should comply with

the relevant sections of these codes.

In addition, particular industries or end users may have specific

requirements relating to the safety of their installations, and these

requirements should also be met".