24

Section VI – Installation

A. Installation Drawings

The installation drawings listed in Table 1 show installation

dimensions, port locations and operating parameters. Man-

ifold, subplate and bolt kit information is also included.

NOTE

Detent valves must be installed with the valve spool

in the horizontal position for good machine

reliability. The mounting position of spring offset and

spring centered models is unrestricted.

NOTE

Make sure the “Y” drain port is piped directly to the

tank. Back pressure cannot be tolerated at this

valve port.

CAUTION

On solenoid operated directional valves make sure

an electrical ground is connected to the valve. This

prevents the possibility of a shock hazard if a coil

develops a short circuit to the frame.

B. Fluids and Seals

Standard seals (Nitrile) can be used with petroleum,

water-glycols, and water-oil emulsion type fluids.

F1 seals (Butyl, EPR) must be used for alkyl phosphate-es-

ter base fluids and aircraft type fire-resistant fluids. F1 seals

cannot be used with petroleum or phosphate ester-hydrocar-

bon blends.

F3 seals (Viton*) can be used with all commonly used

industrial hydraulic fluids. Viton* is compatible with

petroleum, water-base and synthetic fire-resistant fluids.

*Trademark of Dupont DeNemours Co., Inc.

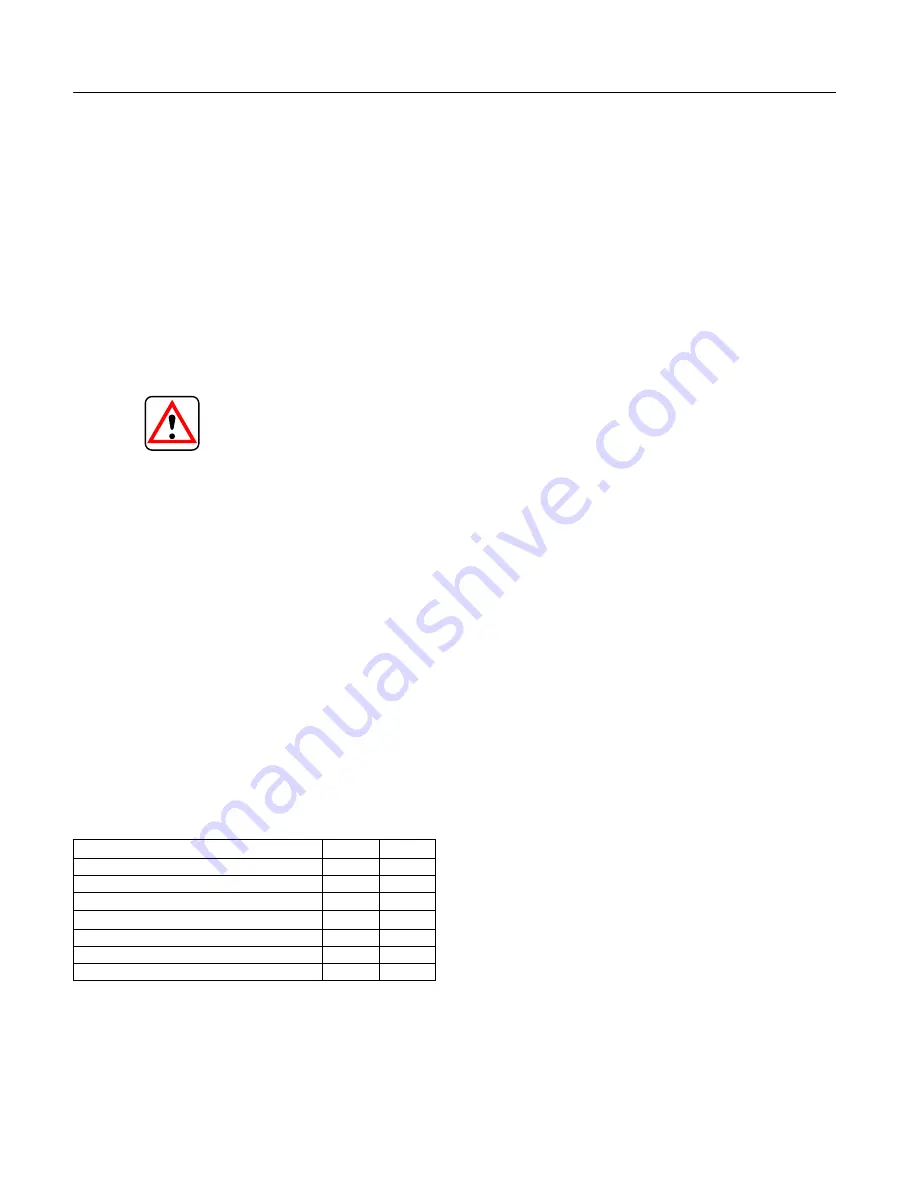

Fluid Type

Skydrol

Yes

No

Pydraul 10-E

Yes

No

Pydraul 29-E-L-T, 50-E, 65-E, 115-E

Yes

Yes

Pydraul 230-C, 312-C, & 540-C

No

Yes

Fyrquel & Fyrlube

Yes

Yes

Fyrtek

No

Yes

Houghto Safe 1000 Series

Yes

Yes

The following table summarizes the compatibilities of the

most common phosphate ester fluids.

F3

F1

C. Piping and Tubing

1. All pipes and tubing must be thoroughly cleaned

before installation. Recommended cleaning methods are

sandblasting, wire brushing and pickling. Refer to instruction

sheet 1221-S for pickling instructions.

2. To minimize flow resistance and the possibility of

external leakage, use only the necessary fittings and con-

nections required for proper installation.

3. The number of bends in tubing should be kept to a

minimum to prevent excessive turbulence and friction of fluid

flow. Tubing must not be bent too sharply. The recom-

mended radius for tube bends is three times the inside

diameter.

D. Hydraulic Fluid Recommendations

Hydraulic fluid within the system performs the dual function

of lubrication and transmission of power. To insure proper

lubrication, system life, and component reliability, fluid

selection should be made carefully with the assistance of a

reputable supplier. Fluid selection should be acceptable for

use with all valves, motors and pumps within the system.

Data sheets for fluid selection are available from your local

Sales or Engineering representative to order data sheet

I-286-S.

The fluid recommendations noted in the data sheet are

based on our experience in industry as a hydraulic

component supplier. Where special considerations indicate a

need to depart from these recommendations, see your sales

representative.

E. Cleanliness

To insure your hydraulic system is clean, perform the

following steps:

1. Clean (flush) the entire system to remove paint, metal

chips, welding shot, etc.

2. Filter each oil change to prevent introduction of

contaminants.

3. Provide continuous oil filtration to remove sludge,

products of wear and corrosion generated during the life of

the system.

4. Provide protection to all areas that can introduce

airborne contaminants into the system.

5. Perform regular servicing procedures of filters,

breathers, and reservoirs.

F. Overload Protection

A relief valve must be installed in the system as close to the

pump as possible. The relief valve limits pressure in the

system to a prescribed maximum. The setting of the relief

valve depends on the work requirements of the system.