DRAFT - 07 March 2016

DRAFT - 07 March 2016

INM MTL GECMA WS display rev 2

32

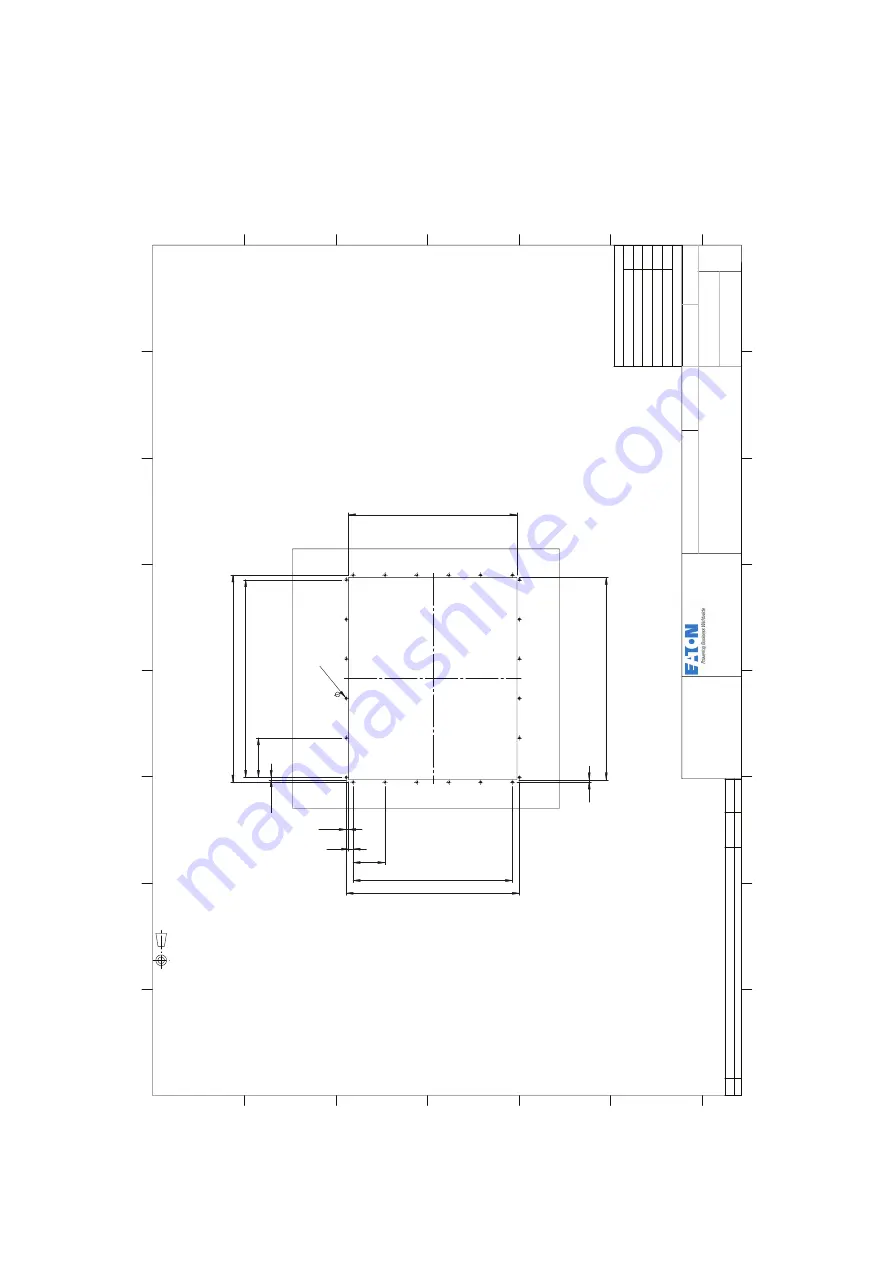

Appendix A – Display panel cut-out and mounting dimensions

The following drawings show the necessary dimensions of cutting and drilling

operations appropriate to the mounting of the individual display models.

MTL GECMA WS 19” display cutout

5,5

93

(5x93=)465

5,65

10,5

75

(5x75=)375

5,5

476

396

5,5(24x)

407,3

487

TOLERANCE TABLE

GENERAL TOL

±0.3

HOLE CENTRES

±0.1

HOLE DIA

±0.1

ANGLES

±0.5°

ENCL OVERALL DIMS

±2

UNLESS OTHERWISE SPECIFIED

2

Drawing border changed

02.02.2016

MW

REV.

DESCRIPTION

DATE

DRN BY

2

Iss.

SolidWorks

A3

Eaton's Crouse-Hinds Division, GeCma Components electronic GmbH Heinrich-Hertz-Str. 12 D-50170 Kerpen Telephone: +49 (0)2273 9812-0 Web: www.gecma.com

Title

F

E

D

C

B

A

Scale 1:5

Drg. No.

Third Angle Projection

Do Not Scale

Dimensions in mm

Sheet 1 of 1

10104560

1

2

3

4

5

6

7

8

3

6

4

7

2

1

5

8

E

A

C

B

F

D

Material

Cut-out drawing RT19 Display

SAP-No.

This drawing and any information or descriptive material set out on it are the confidential and copyright property of Gecma Components electronic GmbH (Eaton's Crouse-Hinds Division) and MUST NOT BE DISCLOSED, COPIED, LOANED in whole or part or used for any purpose without the written permission of Gecma Components electronic GmbH (Eaton's Crouse-Hinds Division).

Weight

kg