EATON

Torque Limiting Coupling Installation, Operation and Maintenance Manual E-MEQD-II002-E September 2015

11

Torque Limiting Coupling

2.5.3.6 Tighten the locknut sufficiently to take up all axial

clearance in the bearing/spacer/snap ring assembly.

2.5.3.7 Slide the housing back over the bearing and install

the snap ring.

2.5.3.8 Secure and tighten the bearing housing to the

adapter plate using four hex head screws and

lockwashers. Tighten the screws to 35 ft.-lbs.

(47 Nm).

2.5.3.9 After completing assembly, lubricate both bearings

with No. 2 EP grease.

2.6

Installation of element and drum

2.6.1

Note the orientation of the drum flange with respect

to the air connection(s) on the element and slide the

drum into the element.

2.6.2

Attach the axial locking device to the drum flange

with the appropriate screws and lockwashers.

There are tapped holes in the drum flange to accept

the screws.

2.6.3

Separate the (motor and pinion) shafts as far as the

bearing clearances will allow and hoist the element

drum (axial locking device) into position. Take special

care when hoisting the element between the shafts.

The axial locking device mounting plate can easily

bind against the spider face.

2.6.4

Attach the drum to the drum hub with the

appropriate fasteners. See Table 1. Make sure the

bore in the drum flange fully engages the pilot

on the drum hub.

2.6.5

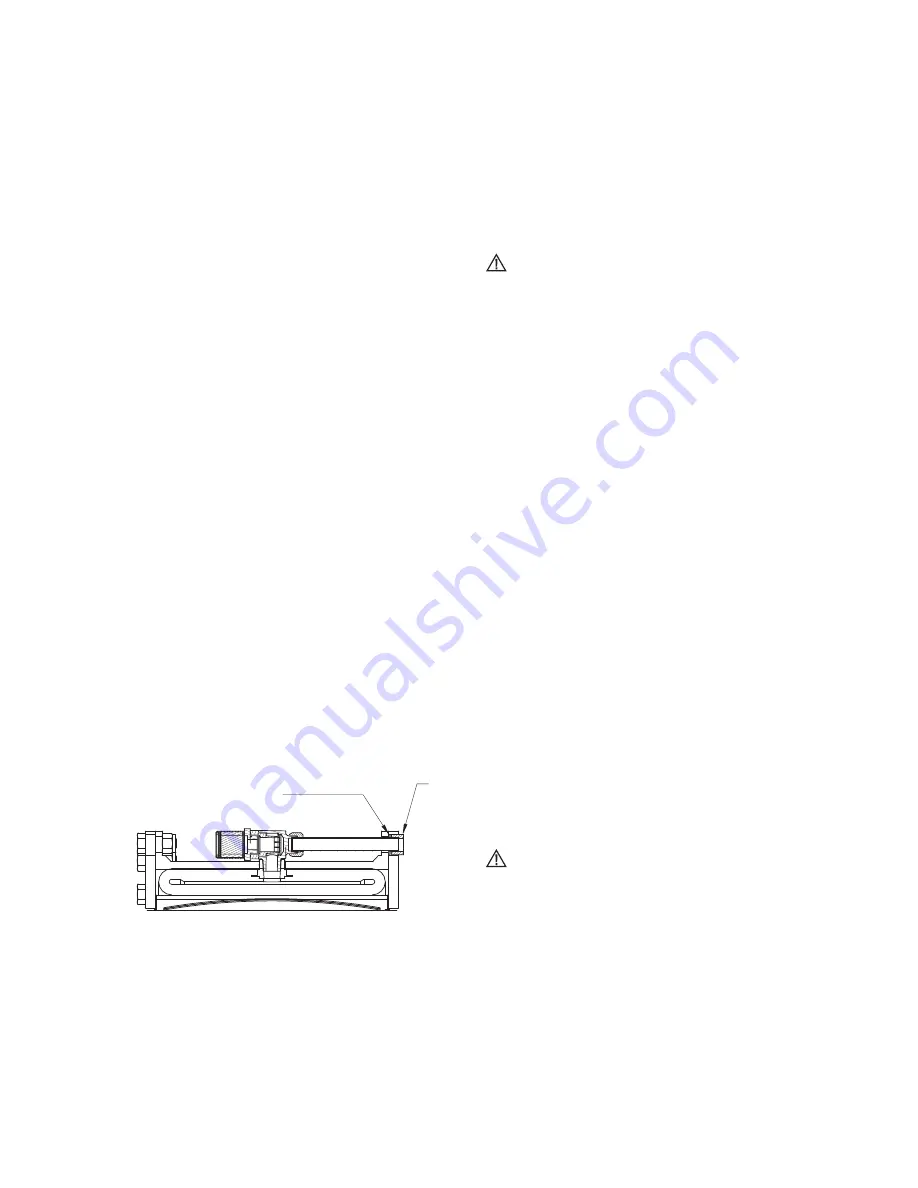

Install the air connection gaskets onto the air tubes.

The metal backup washer is to be positioned toward

the elbow (away from the spider). See Figure 9.

2.6.6

Align the element air connections with the passages

in the spider and attach the element to the spider

with the appropriate fasteners. See Table 1.

Make sure the element fully engages the register

in the spider.

2.6.7

Rotate the motor shaft and push the spider towards

the mill until the axial locking device mounting plate

is flush against the spider face and the motor is on

magnetic center. Attach the axial locking device

mounting plate to the spider with the appropriate

screws and lock washers. Tighten the screws.

Caution

Do not attempt to pull the motor shaft back onto

magnetic center by tightening the axial locking device

mounting screws. To do so will damage the axial

locking device.

2.7

Air control system

2.7.1

The typical TLC air control system(s) operating

charateristics vary from one grinding mill to another,

following are some general guidelines for installing

the air controls.

2.7.1.1 The air receiver tank(s) must be located as close to

the TLC as possible (the tank should be located

within 15 feet of the solenoid valve, and solenoid

valve should be within five feet from the rotorseal)

for consistent TLC response.

2.7.1.2 Use full size piping and valves consistent with the

rotorseal size and keep the number of elbows

to a minimum.

2.7.1.3 Use poppet-type solenoid valves. Spool valves should

not be used.

2.7.1.4 An air line lubricator is not required for the TLC

element; however, if one is used, it must be a

nonadjustable, mist-type.

2.7.1.5 Make sure the flow control valve is installed with free

flow (indicated by an arrow on the valve body) away

from the TLC (free flow to exhaust).

2.7.1.6 The final connection to the rotorseal MUST be made

with flexible hose and place no radial load upon the

rotorseal. Also, if the rotorseal is mounted onto the

end of a motor shaft, an insulating coupling must be

installed between the piping and the rotorseal.

Caution

Do not use rigid pipe at the connection to the

rotorseal. Rigid piping will result in excessive loads

on the rotorseal bearings, shortening life.

2.8

Electrical controls

2.8.1

The basic Airflex grinding mill TLC control provides

for engagement of the TLC when the motor is not

running and the mill is not turning. It also monitors

the TLC for slippage during operation and

disengages the TLC if slippage beyond the

allowable user set limits should occur. Refer

to the CP3130 TLC Slip control IOM for details.

Figure 9

Rubber backed washer

Steel Washer

Rubber

backing