11

11

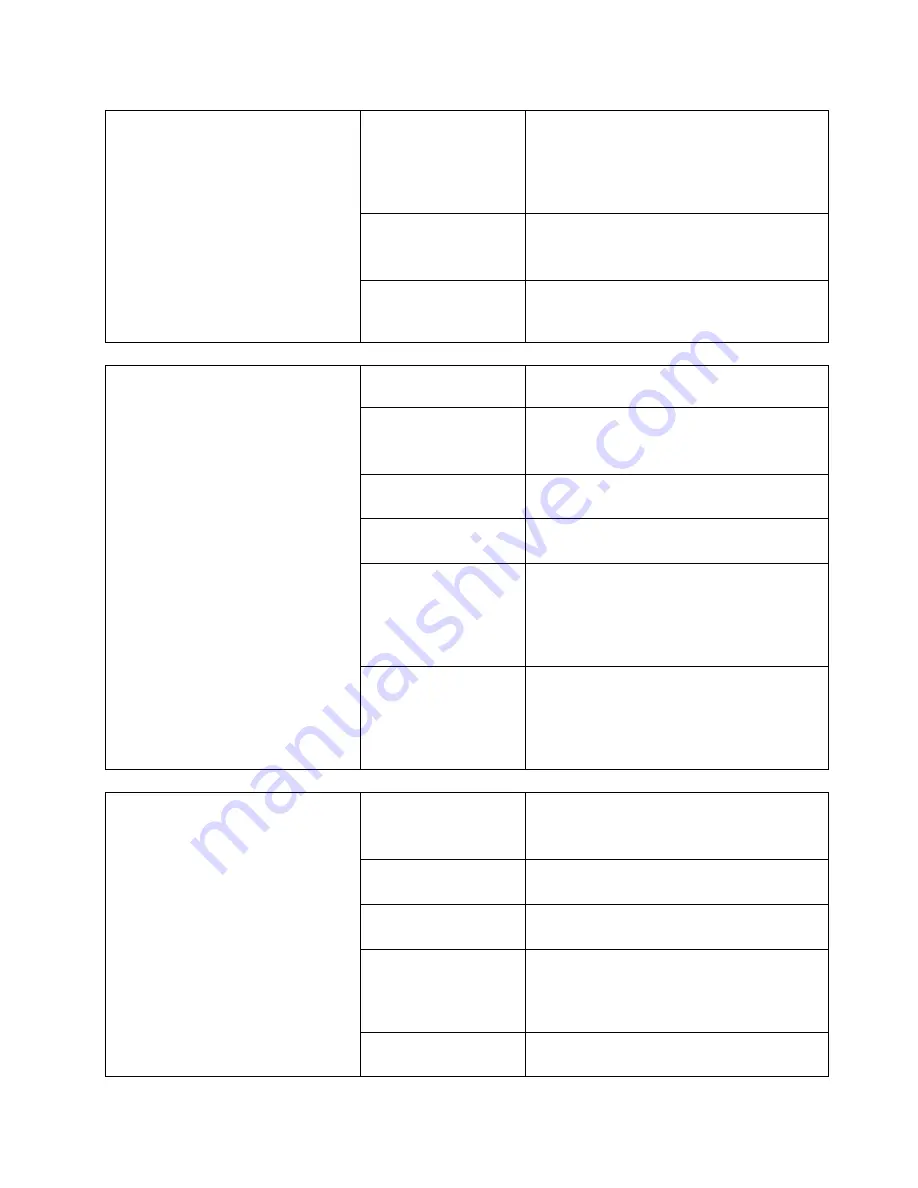

TROuBLESHOOTING

TROUBLESHOOTING

Problem

Cause

Fix

Arc is triggered but will not start

Incomplete Circuit

Check Ground connection. Make sure

that the ground is on a freshly cleaned

surface and close to the welding area. It is

suggested to weld towards the ground

connection.

Incorrect Tungsten

Consult chart for proper tungsten for the

base metal being welded. In most cases

Thoriated will be used for all steels.

No shielding gas

Make sure the shielding gas cylinder is

turned all the way open and set at the

correct flow rate.

Arc wanders and it is

hard to concentrate heat

in a specific area

Poorly prepped

tungsten

Follow guidelines for prepping tungsten.

Poor Gas Flow

Adjust the flow rate of the shielding gas

(refer to settings chart). Check for loose

fittings where gas could be leaking.

Contaminated

Tungsten

Remove tungsten from torch and break

off contaminated section and resharpen.

Incorrect arc length Make sure the tungsten is held 1/8 to 1/4

inch off the work piece.

Incomplete circuit

Check Ground connection. Make sure

that the ground is on a freshly cleaned

surface and close to the welding area. It

is suggested to weld towards the ground

connection.

Contaminated base

metal

Clean base metal making sure to remove

any oil, debris, coatings, or moisture. If

base metal is aluminum make sure all of

the oxide is removed using either a

dedicated stainless brush or flap wheel.

Porosity in weld bead

Poor Gas Flow

Adjust the flow rate of the shielding gas

(refer to settings chart). Check for loose

fittings where gas could be leaking.

Contaminated filler

metal

Clean filler metal making sure to remove

any oil, debris, or moisture.

Contaminated base

metal

Clean base metal making sure to remove

any oil, debris, coatings, or moisture.

Poor Shielding

Make sure to be in an area with no wind

and with any fans turned off. Wind or

fans will blow the shielding gas away

from the weld causing porosity.

Incorrect Tungsten

Stick Out

Adjust the tungsten so that 1/8 to ¼ inch

is sticking out of the collet.