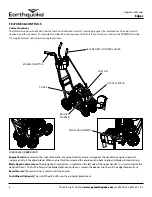

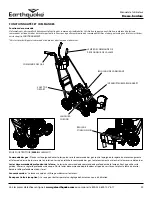

ASSEMBLY INSTRUCTIONS

INSTALL HANDLEBAR

1. Position dash panel between the lower handlebar attach

points. Position the upper handlebar outside of the lower

handlebar attach points. Attach handlebars and dash panel to

the handlebar mount with 6 x M6X20 bolts and 6 x M6 nuts.

SEE FIGURE 1.

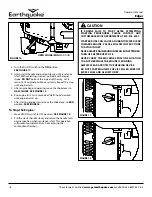

IMPORTANT

ENSURE BLADE DOES NOT TURN WHEN LEVER IS IN

TOP NOTCH (DISENGAGED) BY SLOWLY PULLING

ENGINE RECOIL AND OBSERVING THAT THE BLADE

DOES NOT ROTATE.

ASSEMBLY

UNPACKING

1. Set aside the operator’s manual and parts bag. Carefully lift

the top foam out of the box, remove all loose parts from both

the top and bottom foam packaging.

2. Parts Bag Content

Note: Ensure that all parts have been removed from

inside and underside slots of foam packaging.

KEY DESCRIPTION

23275

QTY.

24000

QTY.

1

BOLT M8 X 25

3

3

2

BOLT M8 X 30

1

1

3

BOLT M6 X 20

6

6

4

BOLT M8 X 20

1

1

5

NUT M8

5

5

6

NUT M6

6

6

7

NUT M10

2

2

8

COTTER PIN 2 MM

6

8

9

SPACER AXLE

4

2

10

SPACER WHEEL POSITION

1

1

11

DOUBLE ANGLE BRACKET

1

1

12

WASHER M12

2

5

13

STRAP CUP HOLDER

1

1

14

WASHER M10

6

6

INSTALL TOOL HOLDER AND HEIGHT ADJUSTMENT

CONTROLS

2. Position the tool holder strap onto the front of the tool

holder. Then position the tool holder onto the front of the

handlebar mount plate. Position the blade height control

on the backside of the handlebar mount plate. Attach tool

holder strap, tool holder and blade height controls to the

handlebars with 3 x M8X25 bolts, 1 x M8X30 and 4 x M8 nuts.

The M8x30mm long bolt is attached through the lower left

hand side mount point on the tool holder, when standing at

the operator’s position.

SEE FIGURE 2.

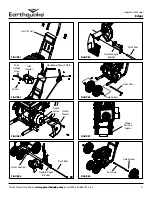

INSTALL CUTTING HEAD ASSEMBLY

3. Remove the clutch shield. Connect the engine belt to the

clutch pulley. Reattach the clutch shield.

SEE FIGURE 3.

4. Position the cutting head assembly onto the pivot location

on the engine mount. Position the double angle bracket onto

the cutting head assembly. Insert the pivot rod through the

double angle bracket, cutting head assembly and engine

mount. Attach the pivot rod to the engine mount with 2 x

M10 washers and 2 x 2mm cotter pins on each end of the rod.

Attach the double angle bracket to the engine mount with 1

x M8 x 20 bolt and 1 x M8 nut.

SEE FIGURE 4 AND FIGURE 5.

NOTE THE ORIENTATION OF THE DOUBLE ANGLE BRACKET

IN FIGURE 5.

INSTALL WHEELS

5. Position the front axle with the front mount points on the

engine mount. Insert the front axle into the engine mount.

Assemble the front wheels in the following order:

1.

Axle spacer

2.

Front wheel (bearing side facing the spacer)

3.

Front wheel (bearing side facing away from the other

wheel)

4.

Axle spacer

SEE FIGURE 6.

Attach the front axle to the engine mount with

2 x M12 washers and 2 x 2mm cotter pins

6. Slide the front wheels, one to each end of the front axle. Clip

the wheel position spacer onto the front axle between the

front wheels.

SEE FIGURE 7.

7. Slide a rear wheel onto the rear axle. Slide an axle spacer

onto the rear axle up to the rear wheel. The rear wheel should

have the bearing side facing the spacer. Position the rear axle

with the rear mount points on the engine mount. Insert the

rear axle into the engine mount and through the other side.

Slide an axle spacer onto the rear axle and then another rear

wheel. Attach the rear axle with 2 x M10 nuts on each end.

SEE FIGURE 8.

Operator’s Manual

Edger

10

Check for parts online at

www.getearthquake.com

or call 800-345-6007 M-F 8-5