European Safety Systems Ltd.

Impress House, Mansell Road, Acton, London W3 7QH

www.e2s.com

Tel: +44 (0)208 743 8880

Document No. D157-00-001-IS

Issue 7

02-11-21

Sheet 2 of 7

2) Warnings

•

DO NOT OPEN WHEN ENERGISED.

•

DO NOT OPEN WHEN AN EXPLOSIVE

ATMOSPHERE IS

PRESENT.

•

POTENTIAL ELECTROSTATIC CHARGING HAZARD.

•

ALL ENTRIES M20 X 1.5MM.

•

IF TEMPERATURE EXCEEDS 70°C AT ENTRY OR 80°C

AT BRANCHING POINT USE SUITABLE RATED CABLE

AND CABLE GLANDS.

•

IF OPENING THE UNIT DURING MAINTENANCE

OPERATIONS A CLEAN ENVIRONMENT MUST BE

MAINTAINED AND ANY DUST LAYER REMOVED PRIOR

TO OPENING THE UNIT.

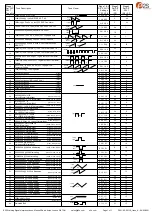

3) Marking & Rating Information

All units have a rating label, which carries the following

important information.

Products may have further approvals, see E2S website for

further details.

ATEX / IECEx Ratings

Standards

EN60079-0:2018 EN IEC60079-0:2018

General Requirements

EN60079-1:2014 A/C:2018 EN 60079-1:2014 ed. 7

Flameproof Enclosure ‘d’

Model No:

Rating

GNExS1DC024

GNExS1DC048

GNExS1AC230

Ex db IIC T4 Gb for Ta

–

60°C to +50°C

Ex db IIC T3 Gb for Ta

–

60°C to +70°C

Ex db IIB T6 Gb for Ta

–

60°C to +50°C

Ex db IIB T5 Gb for Ta

–

60°C to +65°C

Ex db IIB T4 Gb for Ta

–

60°C to +70°C

Certificate No.

SIRA 13ATEX1139X

IECEx SIR 13.0029X

Epsilon x

Equipment Group

and Category:

II 2G

CE Marking and

Notified Body No.

2813

4) Zones, Gas Group, Category and

Temperature Classification

The units can be installed in locations with the following

conditions:

Area Classification

Zone 1

Explosive gas air mixture likely to occur in

normal operation.

Zone 2

Explosive gas air mixture not likely to occur in

normal operation, and if it does, it will only exist

for a short time.

Gas Groupings

Group IIA

Propane

Group IIB

Ethylene

Group IIC

Hydrogen and Acetylene

Temperature Classification for Gas Applications

T1

450

o

C

T2

300

o

C

T3

200

o

C

T4

135

o

C

T5

100ºC

T6

85ºC

Equipment Category

2G

Ambient Temperature Range

GNExS1

-60°C to +70°C

IP Rating

IP6X to EN/IEC60079-0

IP66 to EN60529

5) Special Conditions for Safe Use

Repair of the Flame Path is not permitted.

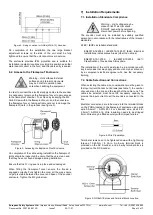

Figure 1: Flame Path.

The enclosure is non-conducting and under certain extreme

conditions may generate an ignition capable level of

electrostatic charge. The user shall ensure that the equipment

is not installed in a location where it may be subjected to

extreme conditions (such as high-pressure steam) which might

cause a build-up of electrostatic charge on non-conducting

surfaces.

6) Product Mounting and Access

6.1. Location and Mounting

The sounder should be secured to any flat surface using the

three 7mm fixing holes (see figure 2). The angle can then be

adjusted as required but the mounting restrictions must be

observed (see outline drawings for details, D157-05-001 for

GNExS1F and D157-05-051 for GNExS1R). This can be

achieved by loosening the two large bracket screws in the side

of the unit, which allow adjustments in steps of 18°.