14

User Manual EE680

Air Velocity and Temperature Sensor for Laminar Flow

5.4.6 Optical Status Indication for Probe and Laminar Flow

Menu Item

Configurable Items

Optical status

indication

Status indication active or inactive

Selection between error indication and laminar flow status

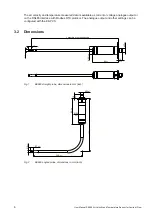

Fig. 15

Selection of optical status indication mode

The status of the laminar flow and the probe is indicated optically by the LED ring embedded in the

probe body.

The user can adjust the behaviour of the optical status indication and choose from the

following options:

Status indication is active / inactive

If active, two status indication modes are selectable :

Error indication - probe status: normal operation

(GREEN)

/ failure

(RED FLASHING)

Laminar flow status: measurand within

(GREEN)

/

out of a given range

(YELLOW FLASHING)

+

Error indication - probe status: normal operation

(GREEN)

/ failure

(RED FLASHING)

The table below summarizes the meaning of LED indication:

Colour

Function / Failure

None

No suitable supply, status indication disabled

GREEN

Probe status: normal operation, no failure

Laminar flow status: measured value in range

YELLOW FLASHING

Probe status: normal operation, no failure

Laminar flow status: measured value out of range

RED FLASHING

Probe status: failure, return sensor for investigation

Tab. 3

Meaning of LED ring light characteristics

The laminar flow status is monitored with the help of one of the measurands and an associated value

range. On delivery, the EE680 monitors the standardized air velocity using the factory preset values

according to Tab. 4. Via the EE-PCS, the standardized air velocity vn or the temperature can be

mode, the status indication shows both, the flow status and the probe status. In case of a probe failure,

the

RED FLASHING

overrides the flow status indication.

Please note:

Setting the parameters for laminar flow monitoring is independent of activation of the

optical status indication. See Fig. 16: The parameters come into effect as soon as the optical status

indication is turned on.