ASSEMBLY INSTRUCTIONS

GENERAL ASSEMBLY INFORMATION

Construction of the Mark VI is very simple when com-

pared to other kits. The printed circuit board for audio has

been preassembled to save you some of the work, and the

assembly that remains is in an open, uncluttered layout to

make wiring quick and easy. The construction time will be

several hours. It is better to work slowly and carefully rather

than concern yourself about the time.

When you unpack the kit, check off the components

against the parts list on page 23. Separate the hardware

items in an egg carton or similar container. You can identify

unfamiliar parts by checking them against the Pictorial

Diagram, bearing in mind that the drawing is necessarily

somewhat distorted for visual separation.

Have the proper tools at hand before starting construction.

The tools necessary are:

1. A pencil-type soldering iron with a 3/16" tip or

smaller of 40 to 60 watts rating, with a tip tempera-

ture of 700 to 800° F.

2. A damp sponge or cloth to wipe the tip of the iron.

3. 60/40

rosin core

solder not larger than 1/16" diam-

eter.

4. A medium sized screwdriver (1/4" blade).

5. Long nosed and diagonal cutting pliers.

6. Heavy "slip joint" pliers.

7. A single edged razor blade or inexpensive wire strip

ping tool for removing insulation.

8. Wood toothpicks.

9. Transparent or masking tape.

10. Heavy cardboard.

We do

not

recommend using a soldering gun. Not only

can a gun provide more heat than is necessary—an unskilled

user might damage printed circuit boards—but also many

users tend to make poor solder connections, simply because

they do not wait long enough for the gun to reach its operat-

ing temperature each time. Use a conventional pencil type

iron.

A good solder connection does not require a large amount

of solder around the joint. A well-made connection looks

smooth and shiny because the solder

flows into the joint

when both parts are hot enough.

There are four steps to making a good solder connection:

1. Make a good mechanical connection.

2. Heat

both

parts with the tip of the iron at the

junction.

3. Apply solder to the

junction

until it melts and flows.

4. Allow the connection to cool undisturbed.

ALL SOLDERING MUST BE DONE WITH

A GOOD GRADE OF ROSIN CORE SOLDER

Under no circumstances should acid core solder be used.

Unmarked solder, cheap solder or any of doubtful origin

should be discarded, and

separate solder fluxes should never

be used.

The warranty is voided on any equipment in which

6

acid core solder or acid type fluxes have been used. Silver

solder is not suitable. The recommended solder is 60/40

(60% tin, 40% lead)

ROSIN CORE.

Do not confuse this

with 40/60, which is harder to use.

You should realize that many of the more delicate com-

ponents are less likely to be damaged in the soldering pro-

cess if you use a hot iron for a short time, rather than a cooler

iron for a longer period. You will also make a better connec-

tion with the hot iron. If you keep the iron clean by wiping

the tip frequently, and occasionally add a small amount of

solder to the tip, it will aid the transfer of heat to the con-

nection. Do not allow too much solder to build up on the

tip though, or it may fall onto adjacent circuitry.

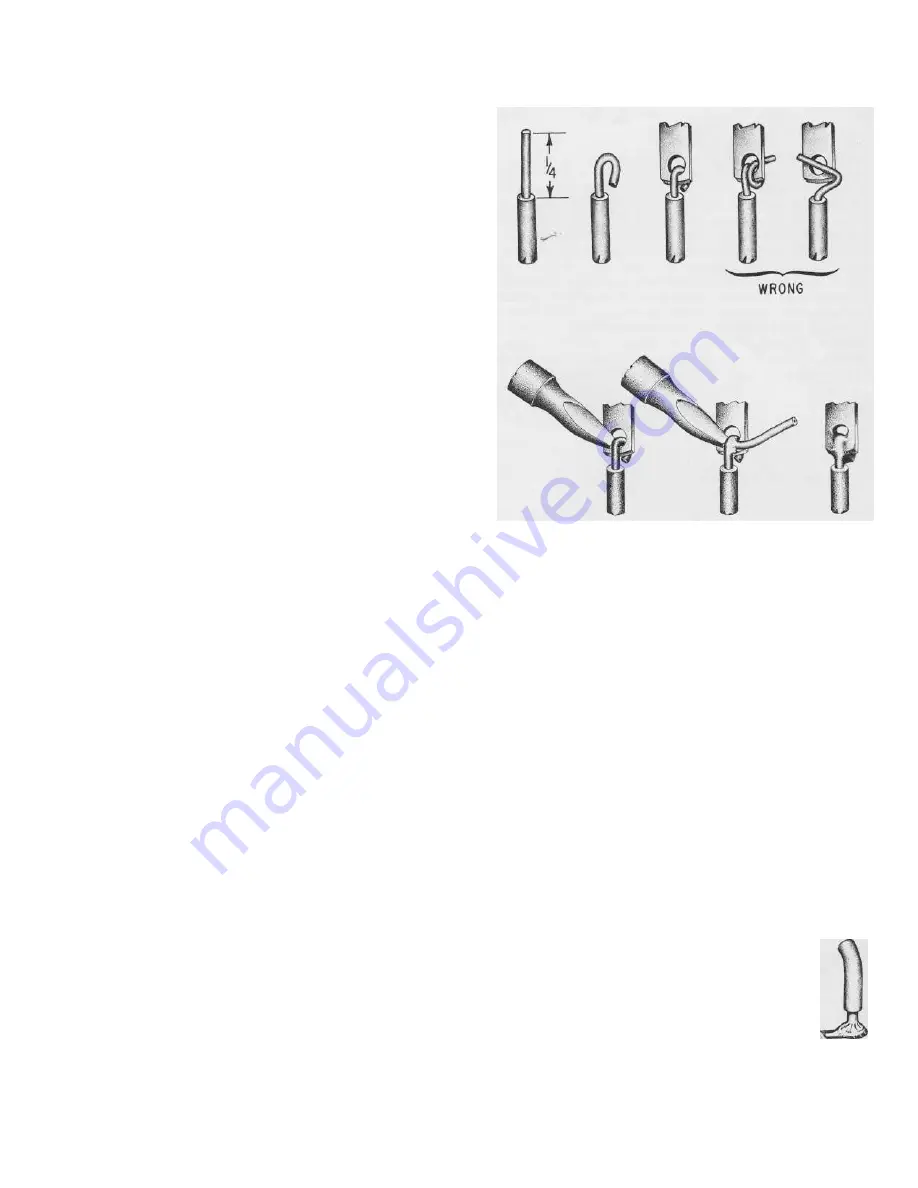

One of the best ways to make a good mechanical connec-

tion is to bend a small hook in the end of the wire, and then

to crimp the hook onto the terminal lug. The amount of bare

wire exposed need not be exactly 1/4 inch, but if it is too

long, the excess might touch another terminal lug or the

chassis. Do not wrap the wire around the lug more than one

time, as this makes the connection difficult to remove if an

error is made.

Many of the wiring steps will call for "preparing" a wire

of a certain length and color. This involves cutting the neces-

sary length of wire and stripping 1/4 inch of insulation from

each end. This is most easily done with wire strippers, but

diagonal cutters can be used if you are careful not to nick

the wire and weaken it.

When soldering a lead to a numbered, plated-

through hole on a circuit board, push the lead

through the hole first.

Do not push the wire all

the way into the hole up to the insulation.

Apply

the solder and the hot iron at the same time to

the junction of the hole and lead. The solder

should melt very quickly; it should flow easily

and fully into the hole and completely around the lead.

Remove the iron and allow the connection to cool. It is

essential

to have a smooth, shiny flow of solder from the lead

to the plated circuitry on the board.