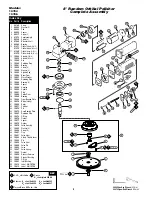

This service chart is published as a guide to expectant life of component parts. The replacement levels are based on average tool

usage over one year. Dynabrade Inc. considers one year usage to be 1,000 hours or 50% of a man year.

Parts Common to all Models:

Preventative Maintenance Schedule

For All 8" Random Orbital Polishers

Index Part

Description

Number High Wear Medium Wear Low Wear Non-Wear

#

Number

Required

100%

70%

30%

10%

1

96168

Screw

1

X

2

94594

Washer

2

X

3

50855

Pad

1

N/A

N/A

N/A

N/A

4

94595

Spacer

1

X

5

95217

Screw

2

X

6

61373

Counterweight

1

X

7

95235

Screw

3

X

8

57069

Balancer Shaft

1

X

9

56052

Bearing

1

X

10

See Note

Orbital Head

1

X

11

See Note

Orbital Head Assembly

1

X

12

See Note

Spindle

1

X

13

18563

Key

1

L

14

18562

Retaining Ring

1

T

15

18561

Bearing

1

T

16

18560

Screw

4

L

17

18559

Washer 4

L

18

18902

Spindle Cap

1

X

19

18593

Bevel Gear

1

X

20

18557

Wave Washer

1

L

21

18556

Retaining Ring

1

D

22

18555

Bearing

3

T

23

18554

Spacer

1

X

24

18552

Housing

1

X

25

18553

Handle

1

X

26

18551

Plug

1

X

27

18594

Pinion Gear

1

X

28

18568

Bearing

1

T

29

18569

Front Bearing Plate

1

X

30

18570

Blade (4/pkg.)

4

T

31

18595

Rotor

1

X

32

18571

Cylinder

1

X

33

18572

Pin

1

X

34

18573

Rear Bearing Plate

1

X

35

18567

Retaining Ring

1

D

36

18574

O-Ring

1

T

37

18576

Gasket

1

T

38

18577

Spacer

1

X

39

18578

Gasket

1

T

40

18579

Valve Housing

1

X

41

18559

Washer

4

L

42

18580

Screw 4

X

43

18601

Grip

1

X

44

18581

Valve Stem

1

X

45

18582

Safety Throttle Lever

1

L

46

18583

Pin

1

L

47

18584

Valve Seat

1

X

48

18585

Valve Pin

1

X

49

18586

Valve

1

X

50

18587

Valve Spring

1

X

51

18588

Gasket

1

X

52

18589

Exhaust Retainer

1

X

53

18592

Exhaust Bushing

1

X

54

18590

O-Ring

1

X

55

18591

Inlet Bushing

1

X

56

See Note

Label

1

X

98224 – Motor Tune-Up Kit

LEGEND

T

Included in Tune-Up Kit

X

Type of wear, no other

comments apply.

L

Easily lost. Care during

assembly/disassembly.

D

Easily damaged during

assembly/disassembly.

R

Replace each time tool is

disassembled.

Note:

Please refer to page 4 of tool manual for specific part number or number required.

7