7

0$5.$1'',5(&7'5,9(,167$//$7,21

,QVWDOODWLRQ3URFHGXUH

1. Unscrew cover. Keep threads clean and free from

damage.

2. Switches are set at factory when in counterclockwise

position. Index marks should appear as shown (Mark

1 only). Set screws, or holes in manual cams, (#2, 4

DQGRQ&ORVHGVZLWFKHVZLOOEHGLUHFWO\DERYH

index marks.

2 Switch Unit #1 Open #2 Closed

4 Switch Unit #1, 3 Open #2, 4 Closed

6ZLWFK8QLW2SHQ&ORVHG

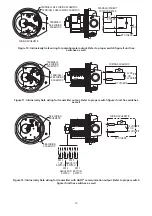

3. Attach appropriate Drive Yoke onto two pins using

DVFUHZSURYLGHG

Note:

Coupling is a special

spring temper yoke or solid metal block. Do not

attempt to fabricate your own yokes.)

4. Attach mounting bracket (127-003 is shown) to

VZLWFKKRXVLQJXVLQJÝVFUHZVSURYLGHG

5. With actuator shaft rotated to its counterclockwise

position, spread the drive yoke and slip it down

onto the square (or rectangular) part of the actuator

shaft. Attach bracket with two hex cap screws. Before

tightening screws, operate control slowly with

a wrench or power, and observe that drive shaft

and drive yoke are concentric and perpendicular

LQFRPSOHWHVWURNH$GMXVWSRVLWLRQDVUHTXLUHGDQG

tighten all the mounting screws. Check concentricity

DQGSHUSHQGLFXODULW\5HDGMXVWSHUDERYHVWHSVDV

necessary.

$GMXVWPHQW3URFHGXUH

A. Using a wrench or power, rotate the actuator shaft to

extreme clockwise position. All switches should

change to their opposite function.

B. The cam can be relocated and repositioned by

ORRVHQLQJWKHVHWVFUHZ7RDGMXVWPDQXDOFDPV

grasp cam on knurled segment of cam surface.

Simply rotate the cam on spline attached to the

VKDIW)HHOLQJRUVRXQGRIFOLFNVLQGLFDWHV

LQFUHPHQWDODGMXVWPHQWV6WRSURWDWLQJDQGUHOHDVH

pressure on cam when it is at proper actuation point.

This allows cam to engage spline. Check the circuit

to verify contact at proper point. Rotate shaft. Repeat

steps above as necessary. Lock manual cam on

spline by tightening set screw provided for additional

security.

C. Screw on cover and tighten against O-ring seal until

cover does not turn.

6HH 3DJHV

for wiring procedure, intrinsic safety

parameters, relevant warnings and schematics.

1.

2.

3.

4.

5.