- 7 -

Pre Installation Preparations

Planning a projection television installation is a critical part of the installation. Even with the extended range

of mechanical and electronic correction circuitry built into the HD-700, incorrect physical placement of the

projector may place it outside the range of the circuits.

Using the

HD-700

Projector installation software provided by DWIN (see www.dwin.com), enter the width of

the screen, the aspect ratio and the mounting position of the projector (ceiling, center of screen or floor). The

program will automatically calculate the correct distance from the screen to the projector. Make certain that

you correctly plan the mounting position and that the information obtained from the planning software is

carefully transferred to the installation venue.

For Floor Mount Installations

Floor mount locations should be level and solid, with an unobstructed view of the screen. DO NOT place the

projector on carpeting or other materials that will interfere with the circulation of air into the ventilation holes at

the bottom of the unit. Also, be careful not to place the projector in a location that is in the direct flow of

heating or cooling vents or in a damp location.

For Center Screen Installations

Follow the same basic instructions as for Floor Mount locations. In addition, make certain that the mounting

location is capable of supporting the weight of the projector.

For Ceiling Mount Installations

Make certain that the ceiling mount bracket is carefully attached to structural beams capable of supporting

the weight of the projector. Then use the handles provided to mount the projector to the bracket. To access

the handles, remove the front portion of the top cover by loosening the two screws on either side of the

green lens and loosening the two screws on the top of the projector. It is not necessary to completely remove

the screws. While holding the cover, pull it upward to remove it from the unit. The handles are the black bars

on the outside of the red & blue lenses.

Plan for connections to the projector of AC power, RGBS connections from the signal source, and a DB-9

connection if the RS-232C port will be used for external control. A separate and properly grounded AC circuit

should be provided. Avoid the use of circuits connected to mechanical equipment, as they may induce noise

in the video system.

Pre Installation Adjustment and Set Up

We strongly recommend that these instructions be followed BEFORE final installation. However, if the

projector is already mounted in place, follow these steps to establish proper operating conditions.

Unpacking

When the unit is first received, verify that the carton does not show any signs that may indicate internal

damage. If damage is suspected, make a report to the freight carrier immediately, and follow their claim

procedures. In addition, please report any carrier damage to DWIN.

If there is no obvious sign of damage, carefully unpack the projector. Due to the weight of the unit two

people should lift the projector from the carton. Carefully place the unit in the location where it will be tested

and inspect it again for any signs of concealed damage that may have been incurred in shipping. Report any

interior damage to the freight carrier and to DWIN.

Before proceeding, you may wish to store the carton for future use should the unit require return to DWIN. If

you discard the carton and shipping material, please observe local recycling rules.

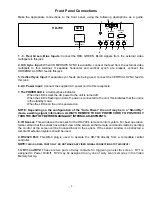

Signal Connections

The HD-700 is an RGB/Sync monitor, which means that it requires an external, video line multiplier

(TranScanner) for video playback. A computer interface may be required for display of computer images.

Connect your video and/or data sources to the external interface or processor, and then connect the RGBS

outputs of the processor, doubler, quadrupler or interface to the signal and sync connections on the HD-

700’s front panel.

If composite sync is used, connect it to the “H/C Sync” terminal. If separate horizontal and vertical sync are

used, make connections to the appropriate terminals. The HD-700 will not operate with “sync on green”.

Connect the AC power cord to the front panel and THEN to a wall mounted AC power outlet. The use of

extension cords is not recommended.