- 13 -

3. Procedures for using the machine

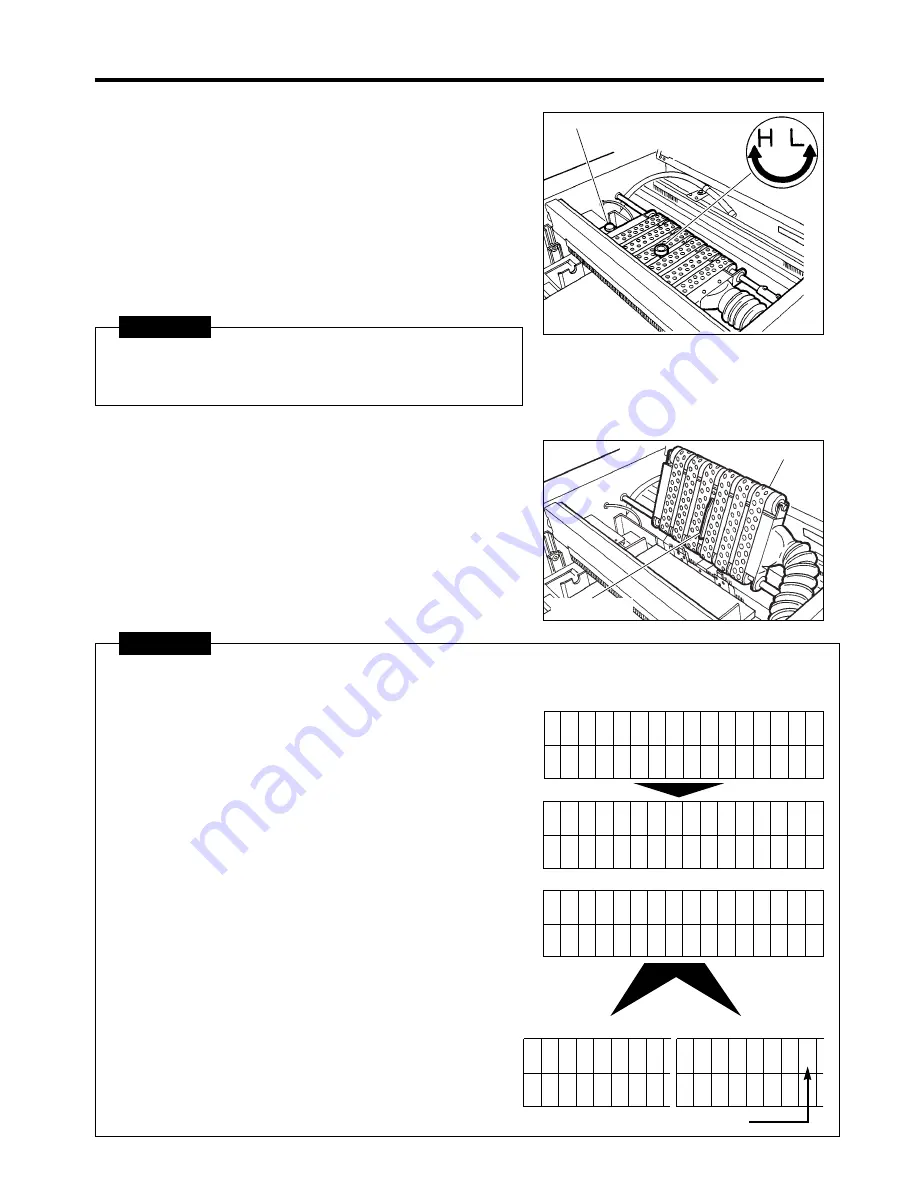

3. Check the separator plate's degree of emergence. To do

so, remove the thumb screw indicated, and open out the

suction unit. This will render the separator plate visible.

1. Press and hold down the F button, and press the MODE

button. The display will change in the way shown at

right.

2. Use the MODE button to select "Normal" or "Heavy".

(Pressing the MODE button toggles the asterisk "

1

"

between the two items. The asterisked item is the one

selected.) Select "Heavy" for thick paper.

3. Press the SET button. The item selected in 2. will be set,

and the RUN mode display will reappear.

*You can tell whether "Normal" or "Heavy" has been set

by the presence/absence of a "

1

" in the Run mode

display. See figure at right.

2. Turn the adjuster knob to adjust the separator plate's

position to match the paper thickness.

The separator plate's standard position is the fully-

emerged position.

¥

For thin paper: Turn the adjuster knob in the "L"

direction to make the separator plate emerge.

¥

For thick paper: Turn the adjuster knob in the "H"

direction to make the separator plate retract.

¥

Adjust the separator plate's position to suit the paper

feed situation.

Thumb screw

Adjuster knob

Suction unit

Separator plate

IMPORTANT

¥

If a jam occurs in the paper feed unit during operation,

carry out the following procedure to eliminate the jam.

IMPORTANT

[

R u n

]

N o . 0 1 :

3 : T

3 0 7 . 0

[

P a p e r

W e i g h t

]

1

N o r m a l

H e a v y

[

P a p e r

W e i g h t

]

N o r m a l

1

H e a v y

[

R u n

]

[

R u n

]

1

¡

When "Normal" is set:

¡

When "Heavy" is set:

Asterisk displayed