29

9.

Maintenance

Caution! Danger of injury!

The maintenance operations should be performed only with the machine switched off and with the motor stopped!

In the following table there are given the operations which should be performed and the respective time intervals between the individual operations.

Operation

Time interval

Removal of the throat plate and its cleaning out.Cleaning out of the wheel feeder, hook and their

surrounding space. Removal of the residues of material and threads from the top roller.

1 day

Checking the oil level in oil reservoirs.

1 month

Checking the hook wear. Checking the function of the safety clutch against the hook overload.

6 months

Checking the V-belt and the indented belts.

1 year

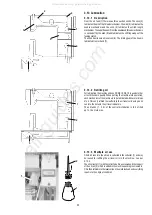

10. Setting the machine according to the sewing category

10.1 Introduction

The sewing machine enables sewing within the extent from the light to medium heavy-duty sewing. The setting of the machine

must be adapted to the sewing parameters including also replacement of some components, such as e.g. needle, the throat plate

insert. For this reason, the setting of the machine is divided into 2 categories:

1 ... light sewing

2 ... medium sewing

In the factory, where this machine has been manufactured, the machine has been set with respect to the standard parameters of

the required sewing category which is designed by the number included in the commercial designation of the machine. If the user

desires changing the given setting to another sewing category, this operation should be performed by a specialized mechanician.

The standard parameters of sewing are described in the following paragraph. The actual parameters of sewing inside the given

sewing category may be different, which means that the machine operative must adapt respectively the setting of the machine,

e.g. the tension of the upper thread.

All manuals and user guides at all-guides.com