6.

If measured superheat is:

• more than required, slowly add refrigerant to obtain

required superheat.

• Less than required, slowly recover refrigerant to

obtain required superheat.

NOTE:

Each time charge is added to or removed

from the system, allow the system to run

approximately 15 minutes before

pressure/temperature readings are re-taken

and superheat calculations made.

TXV System Charging

1.

Operate unit for minimum of 10 minutes.

2.

Measure pressure and temperature at liquid valve

service port. Use a good thermistor or electronic

thermometer.

3.

Subtract measured temperature from saturation

temperature (of measured pressure) measured to

obtain subcooling. Refer to

Table 4

for saturation

temperature of R-22.

4.

The subcooling level should be as specified on the unit

specification sheet. In the absence of the specification

sheet, use 12-14°F subcooling.

5.

If measured subcooling is:

• more than required, slowly recover refrigerant to

obtain required subcooling.

• less than required, slowly add refrigerant to obtain

required subcooling.

Defrost System (Heat Pumps Only)

A defrost system consisting of a defrost thermostat

(mounted to the outdoor coil) and a defrost control board

(in the control box) provides automatic defrosting of the

outdoor unit when required. The defrost function is

initiated and terminated based on time and temperature.

During frosting conditions, the compressor will operate for

30, 60 or 90 minutes (field adjustable, factory set for 90

minutes) before switching to the defrost mode.

In geographical areas where heavy snowfall, freezing

rain, or extensive operation in 20°F-40°F range is

expected, the setting should be changed to 30 or 60

minutes. This is performed by relocating the "RUN TIME"

jumper on the defrost board from the pins labelled "90" to

either the "30" or "60" pins.

The defrost board provides a five (5) minute time delay

for compressor short cycle protection. To bypass this

delay, short the two "TEST" terminals together for 2

seconds.

For defrost system checkout, with the system running in

the heating mode, short the two "TEST" terminals together.

The heat pump will go into the defrost mode for as long as

the "TEST" terminals are shorted together.

Unit Maintenance

The unit should be inspected and cleaned on an annual

basis by a qualified technician. This should include

checking for adequate clearances, electrical connections,

duct connections/blockages, air filters, airflow, lubrication,

and operational performance of system.

Coils may

require cleaning. The coil should always be cold when

cleaning. Use an alkaline-based cleaner only.

Cleaning a hot coil or using an acid based cleaner will

remove the paint from the fins and may clog the coil.

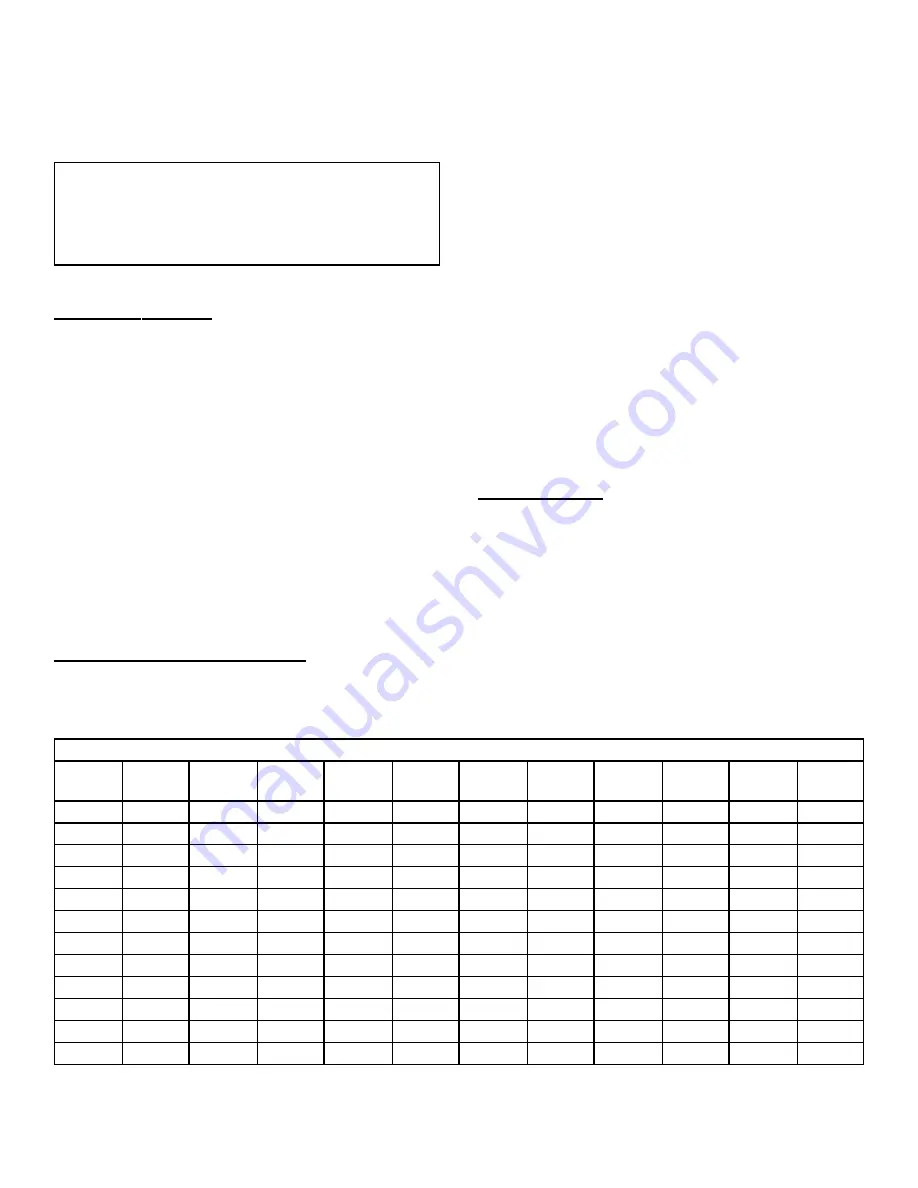

Table 4 - R-22 Saturation Temperature / Pressure Chart

Pressure

(psig)

Temp.

(°F)

Pressure

(psig)

Temp.

(°F)

Pressure

(psig)

Temp.

(°F)

Pressure

(psig)

Temp.

(°F)

Pressure

(psig)

Temp.

(°F)

Pressure

(psig)

Temp.

(°F)

19.3

-6

31.8

9

44.1

21

58.8

33

76.0

45

155.7

85

20.8

-4

32.8

10

45.3

22

60.1

34

77.6

46

168.4

90

22.4

-2

33.7

11

46.4

23

61.5

35

79.2

47

181.8

95

24.0

0

34.7

12

47.6

24

62.8

36

80.8

48

195.9

100

24.8

1

35.7

13

48.8

25

64.2

37

82.4

49

210.8

105

25.6

2

36.7

14

49.9

26

65.6

38

84.0

50

226.4

110

26.4

3

37.7

15

51.2

27

67.1

39

92.6

55

242.7

115

27.3

4

38.7

16

52.4

28

68.5

40

101.6

60

259.8

120

28.2

5

39.8

17

53.6

29

70.0

41

111.2

65

277.8

125

29.1

6

40.8

18

54.9

30

71.4

42

121.4

70

296.7

130

30.0

7

41.9

19

56.2

31

73.0

43

132.2

75

316.5

135

30.9

8

43.0

20

57.5

32

74.5

44

143.6

80

337.4

140

20407502

ISSUE 0144

Page 6 of 8