10. Programming

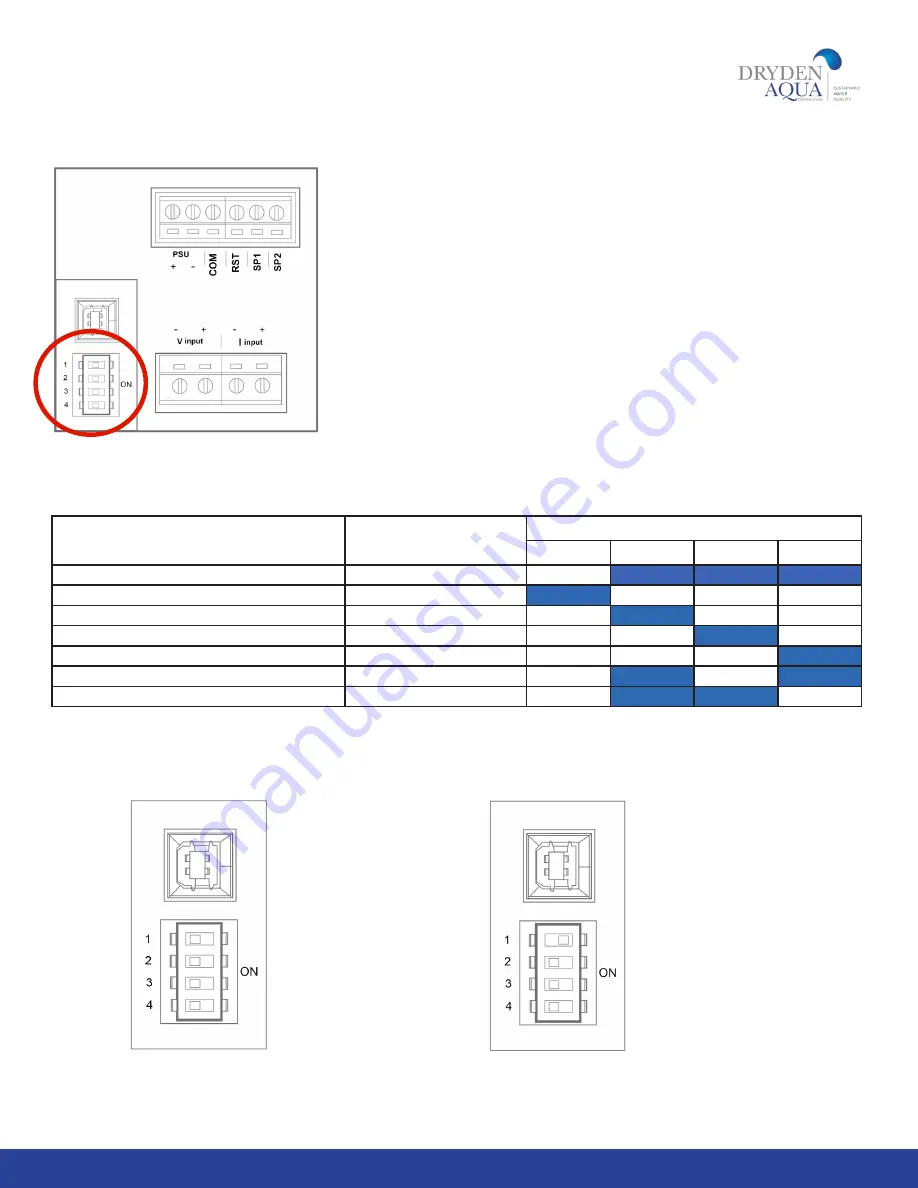

To proceed with programming, first locate the DIP switches on the back side

of the Digital display. Refer to the circled area in Fig.3.2.

Important Note: It is important to select the correct DIP switch position

based on BOTH the model (first column) and the pipe size (second column)

shown in the table below as multiple FlowVis models exist for the same pipe

diameter.

11

Fig 3.3 (left) The

default setting for

the DIP switches (all

switches set to the

OFF position).

Fig 3.4 (left) DIP

switch number 1 set

to the ON position.

Fig 3.2

WWW.DRYDENAQUA.COM

Flowvis model / reference #

Pipe size

DIP - Switch position

1

2

3

4

d 50mm / ref 90020

DN40 / d50mm / 1.5”

OFF

ON

ON

ON

d 63mm / ref 90021

DN50 / d63mm / 2”

ON

OFF

OFF

OFF

d 75mm / ref 90026

DN65 / d75mm / 2.5”

OFF

ON

OFF

OFF

d 90mm / ref 90022

DN80 / d90mm / 3”

OFF

OFF

ON

OFF

d 110mm / ref 90023

DN100 / d110mm / 4”

OFF

OFF

OFF

ON

d 160mm / ref 90027

DN150 / d160mm / 6”

OFF

ON

OFF

ON

d 200mm / ref 90028

DN200 / d225mm / 8”

OFF

ON

ON

OFF