Technical Data

MiTime T721R

Voltage

230V a.c. +10% -10% 50Hz

Switch Rating

2 (1) A 230V a.c. each switch

Ambient temp

Operating: 0º to 45ºC

Storage: -20ºC to 50ºC

Without mains

power

Display: blank

Time: always kept

Programme times: always preserved

Programming

resolution

1 minute

Wiring

Fixed wiring only, to comply with

current IEE regulations

Maintenance

Must be maintained by a qualified

electrician or heating engineer

Pollution degree

2

Rated impulse

voltage

2.5kV

Ball pressure test

temperature

75ºC

Relevant EC

Directives:

2006/95/EC Low Voltage Directive

2004/108/EC Electromagnetic

Compatibility Directive

2006/66/EC Battery Directive

2011/65/EU RoHS Directive

Applied Standards:

En60730-1; En60730-2-7

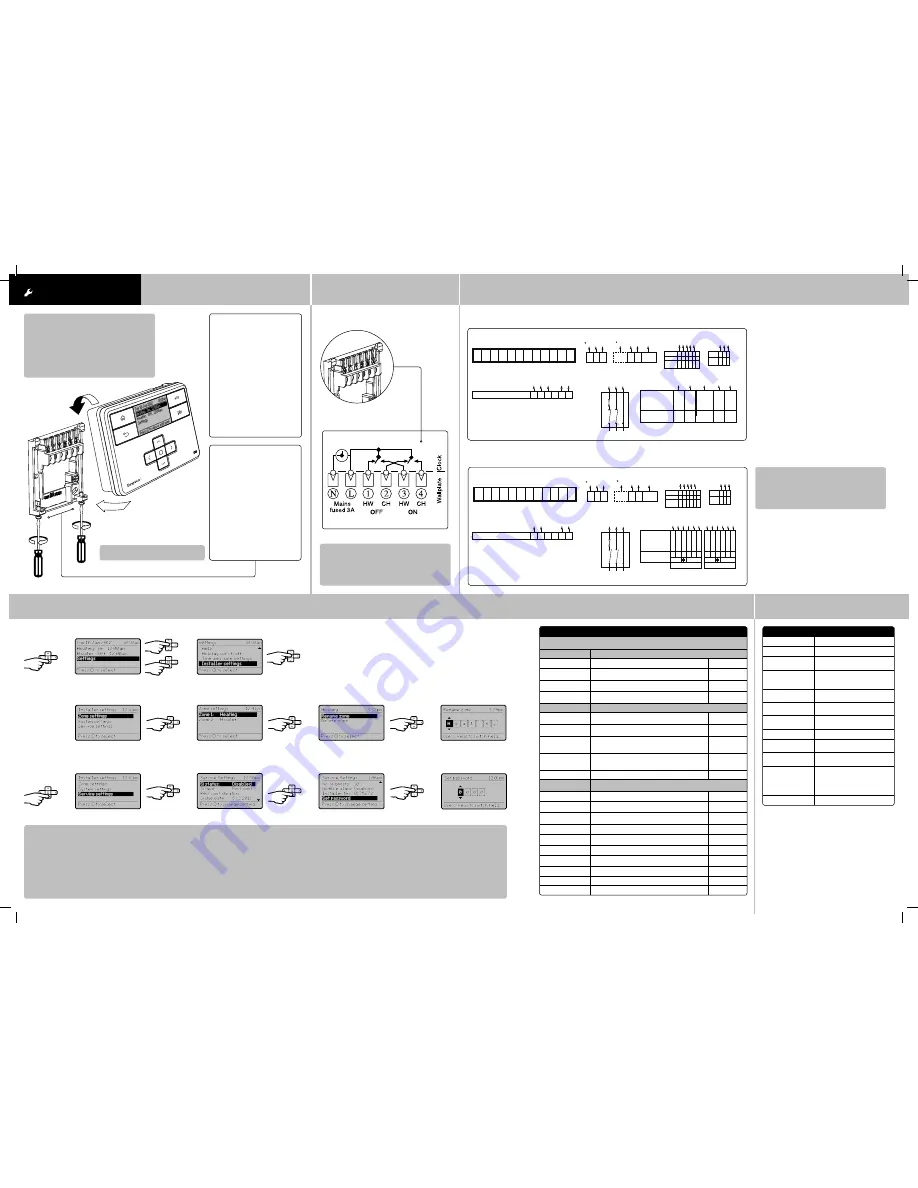

Step 2:

Wiring

→

Connect the wiring as shown below.

Step 3:

Connection Charts

Step 4:

Installer Settings

Arrowed numbers relate to the junction box.

* Consult boiler handbook for details of pump

overrun wiring.

Make the wiring connections, as shown, for the

appropriate system. For surface wiring, snap out the

cable entry strip on the bottom edge of the wall-plate.

MiTime units are double-insulated and need no earth

connection, but an earthing continuity (loop) terminal is

provided for convenience.

After wiring, plug in the unit and tighten the securing

screws. Check the mains input has a 3A fuse, and switch

on the mains.

Biflo system: Model T721R

LWC3 Junction Box

Pump

Room Thermostat

Cyl. Thermostat

Boiler

Mains Input - 230V a.c.

Motorised Valve

*Refer to Boiler Handbook for wiring details of Pump Overrun boilers. Use boiler manufacturers instructions.

Connections: The numbers printed at the tip of each arrow represent the Junction Box Terminals to which those leads or terminals should be connected.

3A

MiTime Programmer

CH

ON

HW

ON

CH

OFF

HW

OFF

L

N

4

3

2

1

2 1 NOT

USED

8 4

L N E

7 2 3

Perm.

L

N E Switch

L

7

1

2 3

DHW VALVE

CH VALVE

Function of

Leads

Drayton

22mm 2 Port Valve

28mm 2 Port Valve

Aux.SW

Motor

N

L

Bro

wn

Blue

Yell/Green

Orange

Gre

y

White

(28mm

only)

N.C

N.O

C

E

6

3

2

7 1 9

5

3

2

7 1 10

Aux.SW

Motor

N

L

Bro

wn

N.C

N.O

C

E

Blue

Yell/Green

Orange

Gr

ey

White

(28mm

only)

The white wire (28mm Valves) becomes live when the valve closes, it is not

used and is wired to 'spare' terminals for safe isolation.

1

3

2

L N E

Mains

Isolator

3 2 1 4 5

COM

CALL

SA

T.

RTS 1&2

RTS 4,6,9&10

Function

N

L 3

N L

E N L

1 3

6

8

COM

CALL

SA

T.

Drayton

HTS 3

Function

C 1 2

1

L

2

N

3

E

4

5

6

7

8

9

10 11 12

LWC3 Junction Box

Pump

Room Thermostat

Cyl. Thermostat

Boiler

Mains Input - 230V a.c.

Motorised Valve

*Refer to Boiler Handbook for wiring details of Pump Overrun boilers. Use boiler manufacturers instructions.

Connections: The numbers printed at the tip of each arrow represent the Junction Box Terminals to which those leads or terminals should be connected.

3A

MiTime Programmer

CH

ON

HW

ON

CH

OFF

HW

OFF

L

N

4

3

2

1

2 1 NOT

USED

8 4

L N E

7 2 3

Perm.

L

N E Switch

L

7

1

2 3

DHW VALVE

CH VALVE

Function of

Leads

Drayton

22mm 2 Port Valve

28mm 2 Port Valve

Aux.SW

Motor

N

L

Bro

wn

Blue

Yell/Green

Orange

Gre

y

White

(28mm

only)

N.C

N.O

C

E

6

3

2

7 1 9

5

3

2

7 1 10

Aux.SW

Motor

N

L

Bro

wn

N.C

N.O

C

E

Blue

Yell/Green

Orange

Gr

ey

White

(28mm

only)

The white wire (28mm Valves) becomes live when the valve closes, it is not

used and is wired to 'spare' terminals for safe isolation.

1

3

2

L N E

Mains

Isolator

3 2 1 4 5

COM

CALL

SA

T.

RTS 1&2

RTS 4,6,9&10

Function

N

L 3

N L

E N L

1 3

6

8

COM

CALL

SA

T.

Drayton

HTS 3

Function

C 1 2

1

L

2

N

3

E

4

5

6

7

8

9

10 11 12

Twinzone system: Model T721R

→

INSTALLATION

Guide

Step 1:

Mounting the Wall-plate

!

IMPORTANT:

Installation must only be carried out by a

qualified electrician or heating engineer.

Make sure mains input has a 3 amp fuse.

!

CAUTION! Before installation, make sure the

mains supply is switched off!

MiTime

Option 2: Using an existing

wall-plate

Loosen the securing screws

on the old programmer and

unplug it. Check that there is

70mm clearance to the right of

the wall-plate and 25mm above

it. Check the wiring diagram for

your product model to compare

terminals and, if necessary,

change the wiring of the wall-

plate to suit. now plug the MiTime

unit into the wall-plate and tighten

the securing screws.

Check the 3A fuse, and switch on

the mains.

Option 1: Fitting a new wall-plate

The ideal location is 1.2m above

floor level, with reasonable

lighting, good access, no

condensation, no extremes of

temperature and a supporting

surface that fully covers the

back of the unit. Position with

70mm clearance to the right,

25mm above and sufficient room

to access the securing screws

underneath. Fix, with terminals

at the top, either direct to a flat

wall using wall plugs and no. 6 x

1” (25mm) woodscrews, or on a

flush mounting single conduit box

type UA1 (BS4662) using M3.5 x

14 bolts.

!

DO NOT use a surface mounting box

→

Feature:

Description:

Factory Pre-Set:

Installer Settings

!

CAUTION!

These settings should only be modified by a qualified

person. They can influence safety and the proper functioning of the system.

Zone Settings

Customise the MiTime according to personal requirements

Select zone

Select a zone for the following actions

Rename zone

To rename an existing zone

Heating,

H Water

Delete zone

To delete an existing zone. The last zone cannot be

deleted

Min. 1 Zone

Add Zone

Add a new zone, apply a name & bind a thermostat.

A time table can be applied.

Max. 2 Zones

System Settings

These are the settings which will be applied to the MiTime unit

View product

information

View the product details, e.g. Part number, Firmware

revision etc.

Backlight settings

Available options are: On with timeout, Always On,

Always Off

On with

timeout

Screen lock

Enable or disable the lock in the MiTime unit

To Lock: Enter a 3 digit code for protection

To Unlock: Enter the 3 digit code

000

Master Code 401

Powersave

To reduce power use when not being adjusted.

Available options are: Powersave off, partial display

with key data, no display until button press

Powersave off

System Reset

Will reset all settings to factory pre-sets

Service Settings

To help comply with regulation 36 of the Gas safety [Installation & Use]

regulations 1998

Si Status

Enable or disable Service mode

Disabled

Si Type

Select between, Reduced Comfort, Switched Off &

no Effect (warnings only)

Reduced

Comfort

Reduced comfort

duration

Set the duration for the reduced comfort setting (0

to 60mins.)

15 min.

Si due date

Set the date the next boiler service is due

Today

Warning start

Set the number of days for the on-screen service due

warning (0 to 60 days)

30 days

Boost status

Enable or disable Service Boost

Disabled

no. of boosts

Set the number of Boosts to be available after service

is due (1 to 99)

10

Audible Alarm

Enable or disable Service Alarm

Enabled

Installer tel

Enter the Installer telephone number if required

Set password

Set password to restrict access to the Service settings

0000

From the Home screen, select

Settings

, then

Installer settings

as shown.

From here you can edit the assigned zones, rename them if required and adjust the Service settings.

If using the Service feature, remember to set the

Password

when complete.

!

IMPORTANT:

Always switch off the mains before removing

the MiTime programmer – and never fit it to a live

wall-plate!

→

LWC3 Junction Box

Pump

Room Thermostat

Cyl. Thermostat

Boiler

Mains Input - 230V a.c.

Motorised Valve

*Refer to Boiler Handbook for wiring details of Pump Overrun boilers. Use boiler manufacturers instructions.

Connections: The numbers printed at the tip of each arrow represent the Junction Box Terminals to which those leads or terminals should be connected.

3A

L N E

7 2 3

Perm.

L

N E Switch

L

7

1

2 3

1

3

2

L N E

Mains

Isolator

3 2 1 4 5

COM

CALL

SA

T.

RTS 1&2

RTS 4,6,9&10

Function

N

L 3

N L

E N L

1 3

7 8

6

COM

CALL

SA

T.

Drayton

HTS 3

Function

C 1 2

1

L

2

N

3

E

4

5

6

7

8

9

10 11 12

MiTime Programmer

CH

ON

HW

ON

CH

OFF

HW

OFF

L

N

4

3

2

1

2 1 8 NOT

USED

6 4

Function

Drayton

22mm 3 Port Mid Position Valve

28mm 3 Port Mid Position Valve

White

Gre

y

Orange

Blue

Yello

w/Green

CH

On

HW

Off

Boiler

Live &

HW On

N

E

2

5

3

8

7

LWC3 Junction Box

Pump

Room Thermostat

Cyl. Thermostat

Boiler

Mains Input - 230V a.c.

Motorised Valve

*Refer to Boiler Handbook for wiring details of Pump Overrun boilers. Use boiler manufacturers instructions.

Connections: The numbers printed at the tip of each arrow represent the Junction Box Terminals to which those leads or terminals should be connected.

3A

L N E

7 2 3

Perm.

L

N E Switch

L

7

1

2 3

1

3

2

L N E

Mains

Isolator

3 2 1 4 5

COM

CALL

SA

T.

RTS 1&2

RTS 4,6,9&10

Function

N

L 3

N L

E N L

1 3

7 8

6

COM

CALL

SA

T.

Drayton

HTS 3

Function

C 1 2

1

L

2

N

3

E

4

5

6

7

8

9

10 11 12

MiTime Programmer

CH

ON

HW

ON

CH

OFF

HW

OFF

L

N

4

3

2

1

2 1 8 NOT

USED

6 4

Function

Drayton

22mm 3 Port Mid Position Valve

28mm 3 Port Mid Position Valve

White

Gre

y

Orange

Blue

Yello

w/Green

CH

On

HW

Off

Boiler

Live &

HW On

N

E

2

5

3

8

7

!

IMPORTANT:

Always switch off the mains before removing

the MiTime programmer – and never fit it to a live

wall-plate!

Internal Wiring

→

→

→

→

→

→

→

→

→

→

✎

Installer Notes:

6444 Invensys MiSeries 2 Channel 06490187001 IssE.indd 2

27/09/2013 09:09