– 5 –

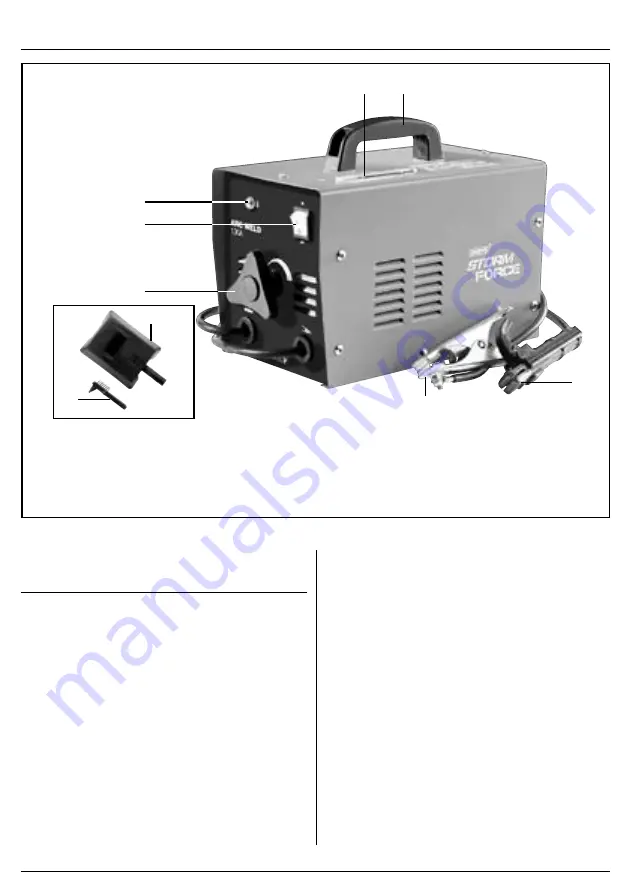

5. IDENTIFICATION – FIG.A

(1)

(2)

(3)

(5)

(8)

(9)

(7)

(6)

(4)

FIG.A

(1)

Carry handle

(2)

Welding current indicator

(3)

On/off switch

(4)

Thermal overload indicator

(5)

Current adjustment control

(6)

Electrode holder

(7)

Direct fit earth clamp

(8)

Face mask

(9)

Brush/hammer

6. ASSEMBLING THE

WELDER

Make sure the power supply information on the

machine’s rating plate is compatible with the power

supply you intend to connect it to.

A suitable plug must be fitted by a qualified

electrician.

This machines wiring has insulation stripped in

preparation for wiring a 16A plug (not supplied).

It is designed for connection to a 16amp

power supply

rated at 230V AC.

Because it is constructed mostly of metal parts, it is a

Class 1 machine; meaning, it must have an earth

connection in the power supply. This is to prevent

electrocution in the event of a failure.

NOTE: Remove the plug from the socket before carrying

out adjustment, servicing or maintenance.

Check that the electrical supply delivers the voltage and

frequency corresponding to the welding machine and

that it is fitted with a delayed fuse suited to the maximum

delivered rated current.

NOTE: The welding machines are set to the highest

voltage at the factory.

6.1 PREPARING THE WELDING

CIRCUIT

Connect the ground “lead” to the piece to be welded.

Connect the welding electrode to the electrode holder.

When the machine is turned on and the electrode

touches, the workpiece, the electrical circuit is complete,

this will result in the welding arc being produced.