Adjust Limits in User Mode

1.

Move motor to limit

(upper or lower)

to be changed. Screen must move

to previously set limit and will stop

automatically.

2.

Hold UP and DOWN buttons until motor

jogs.

3.

Move motor to its new limit location and

hold MY/STOP button until motor jogs.

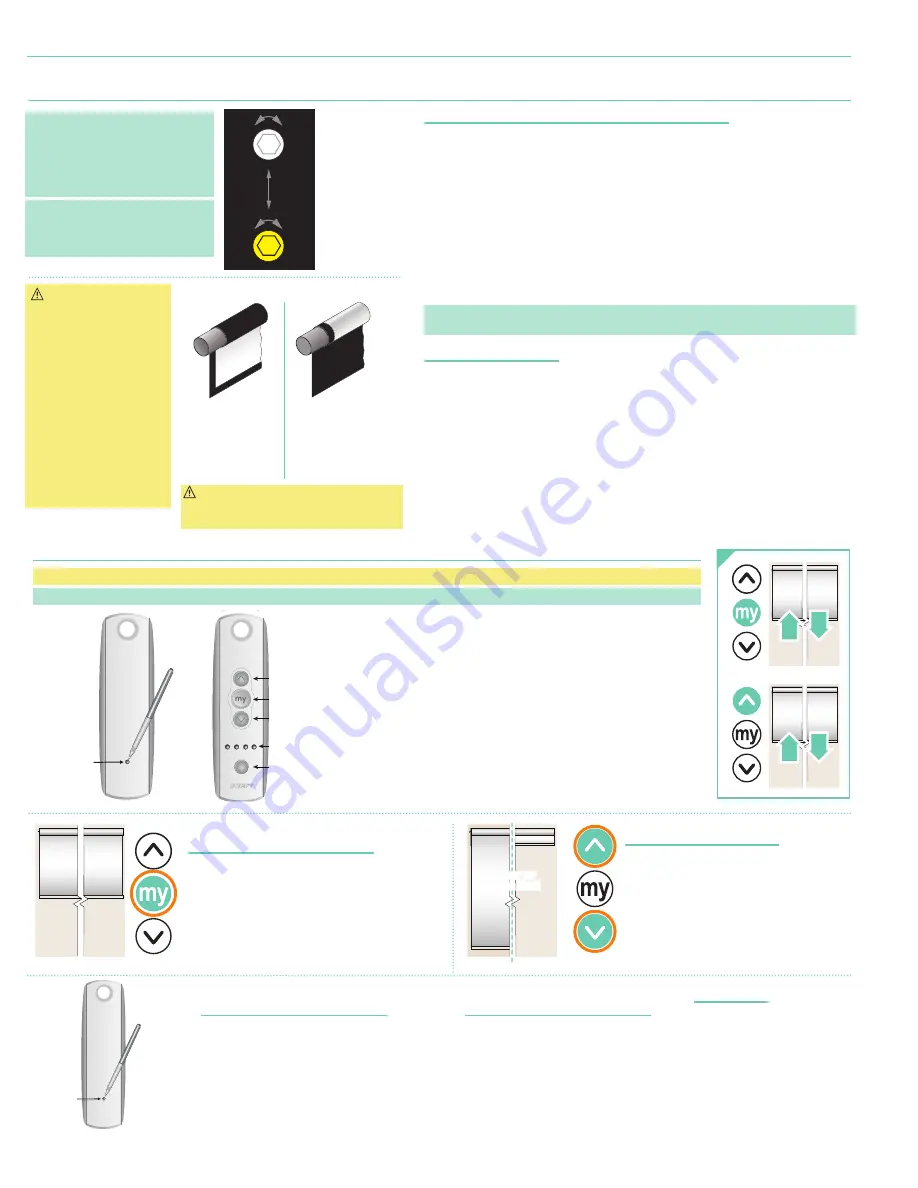

Section 6 -

RF Remote Programming Instructions

(ONLY used if optional RTS Motor is specified)

IMPORTANT:

This section

ONLY

applies if optional RTS Motor has been ordered.

Please Note:

The motor ships with no programming. Follow these instructions to program unit to the desired transmitter.

1.

Select a transmitter channel to assign motor. Hold UP and DOWN

buttons until motor jogs, then release.

2.

Check motor direction. To reverse motor direction, hold MY/STOP

button for 5 seconds until motor jogs. Check direction again.

3.

Move motor to upper limit position. Hold MY/STOP and DOWN

buttons until motor moves down, then release. Use UP and DOWN

buttons to move screen to correct lower limit and press MY/STOP.

4.

While motor is at lower limit, hold UP and MY/STOP buttons until

motor moves up, then release. The screen should move to upper

limit and stop.

5.

Next, hold MY/STOP button until motor jogs.

6.

Put motor into USER MODE by holding small programming button

on the back of transmitter and waiting for motor to jog.

Setting an Intermediate Stop -

Screen MUST BE in USER mode.

1.

Move screen to desired mid-point location and

hold MY/STOP button until motor jogs.

2.

To test, press the MY/STOP button when

motor is standing still. The screen will move to

that intermediate location.

3.

To delete an intermediate stop, go to the

intermediate stop and hold the MY/STOP

button until motor jogs.

Add a Channel -

Screen MUST BE in USER mode.

1.

Select channel currently operating

motor, then hold programming

button until motor jogs.

2.

Select new channel to add to

motor, then hold programming

button until motor jogs.

3.

The motor should now work on

both old and new channel.

Delete a Channel -

Screen MUST BE in USER mode.

1.

Select channel operating motor

desired, then hold programming

button until motor jogs.

2.

Select channel to remove, then

hold programming button until

motor jogs. Motor should now

only work on channel kept from

Step 1.

Reset Motor

1.

Disconnect for 3 seconds,

reconnect for 10 seconds,

disconnect for 3 seconds.

Screen will roll.

2.

Hold program button on

remote and wait for 2

separate jogs.

Motor is now reset.

Section 5 -

Limit Adjustments

(Standard Motors)

Figure 7

"Down" Limit Adjustment

(requires

5/32

" (4mm) Allen wrench)

To Reduce Screen Drop:

1.

Raise screen surface approximately 1'

(30cm)

above desired setting and turn off.

2.

Turn DOWN

(I)

limit screw clockwise

(3 screw turns =

1/2

roller revolution)

.

3.

Test by lowering screen. Repeat steps 1 & 2 until desired position

is reached.

To Increase Screen Drop:

1.

Lower screen to down limit.

2.

With down switch on, turn DOWN

(I)

limit screw counterclockwise

(3 screw turns = ½ roller revolution)

to increase drop.

3.

Test by raising screen approximately 1'

(30cm)

then lower to new down limit.

4.

Repeat steps 2 and 3 until desired position reached.

Please Note:

For Quiet Motor with alternate limit screws:

WHITE screw = UP and RED screw = DOWN.

(Fig. 10)

.

"Up" Limit Adjustment

If Screen Raises Too High:

1.

Lower screen surface approx. 1'

(30cm)

below desired setting and turn off.

2.

Turn UP

(II)

limit screw clockwise

(3 screw turns = ½ roller revolution).

3.

Test by advancing screen up.

4.

Repeat steps 1 through 3 until desired position is reached.

If Screen Needs to Raise Higher:

1.

Lower screen surface approx. 1'

(30cm)

below desired setting and turn off.

2.

With UP switch on, turn UP

(II)

limit screw counterclockwise

(3 screw turns =

1/2

roller revolution)

.

3.

Repeat steps 1 and 2 until desired position is reached.

CAUTION:

- Be sure all switches

are in “off" position

before adjusting limit

switches.

- Be prepared to shut off

manually while testing.

- Screen may be

damaged by lowering

it too far and

exposing roller.

- Motor must be

installed so that limit

switches are pointed

down.

Left hand motor:

White Socket—Down

Yellow Socket—Up

Right hand motor:

White Socket—Up

Yellow Socket—Down

Left hand motor:

White Socket—Down

Yellow Socket—Up

Right hand motor:

White Socket—Up

Yellow Socket—Down

Standard Roll

Motor

End

Audience

Side

Reverse Roll

Motor

End

Back

Side

CAUTION:

DO NOT allow dowel to

wrap over roller when operating screen!

This could damage screen.

Figure 6

Please Note:

Screen limits

are factory set for optimum

performance. Any adjustment of

these limits could void the warranty.

Please check with Draper prior to

resetting screen limits.

Please Note:

If Screen is “Right

Hand Motor" the WHITE/DOWN

(I)

and YELLOW/UP

(II)

limit screws

are reversed

(Fig. 7)

.

lI

I

+

+

DOWN Limit

(I)

:

Clockwise

decreases

down

travel.

UP Limit

(II)

:

Counterclockwise

increases

up

travel.

Channel

Selector

UP

STOP

DOWN

LED Lights

BACK

Programming

Button

Pen

Programming

Button

Pen

upper or

lower limit

page 8 of 12

N E