8. PREPARING THE WELDER

15

8.4 GAS/NO GAS WELDING PRINCIPLE

For a successful weld joint, the molten metal must be protected from contaminating gases

found in the air. This is either achieved by supplying the torch with gas from a bottle or

setting the machine up for no-gas and using a flux cored filler wire. The flux shield is

produced as the wire melts.

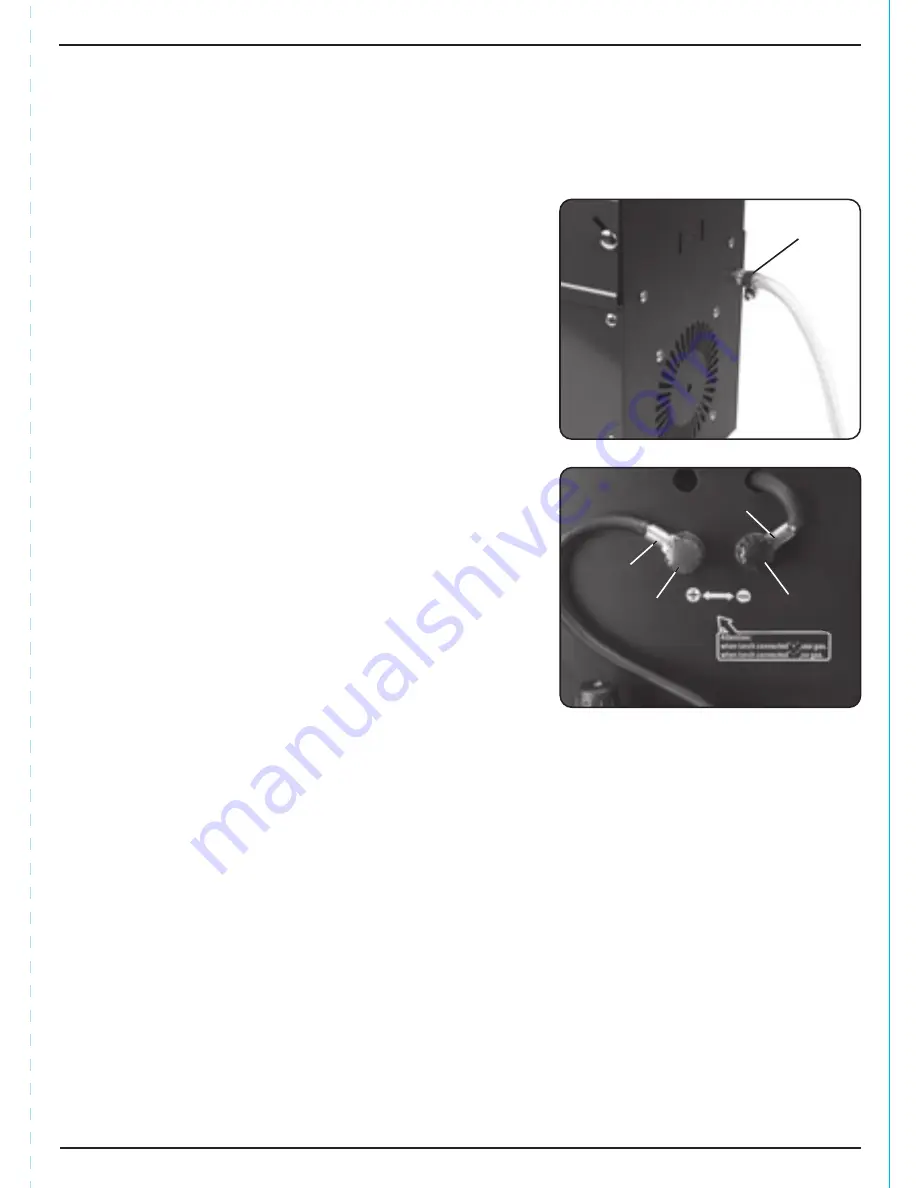

8.5 GAS BOTTLE CONNECTION – FIGS. 6

We recommend the use of a medium capacity gas

bottle for ease of connection.

– Attach a suitable gauge gas hose to the

gas bottle connector

and secure with a

hose clip and attach the other end to a suitable

regulator and gas bottle.

FIG.6

FIG.7

8.6 POLARITY – FIG. 7

The polarity of the torch and earth clamp must be

made correctly to suit the gas setup.

The connectors and terminals can be accessed by

lifting the top cover

.

i Attach the earth clamp connector

to the positive (red) terminal

.

ii Attach the direct (welding torch) connector

to the negative (black) terminal

.

Note:

This configuration is for no-gas (flux cored)

welding. Reverse the torch and earth clamp for gas

welding.

Summary of Contents for MIG100GG

Page 22: ...22 NOTES ...

Page 23: ...23 NOTES ...