Please note:

If needed, the fabric panel heights can be adjusted so that the bottom

edges of the fabric panels are aligned. On large units, this procedure should be

done on only one panel at a time to minimize the amount of fabric weight that must

be supported during the adjustment procedure. Install and adjust rear/upper panls

before beginning on lower/front panels.

1.

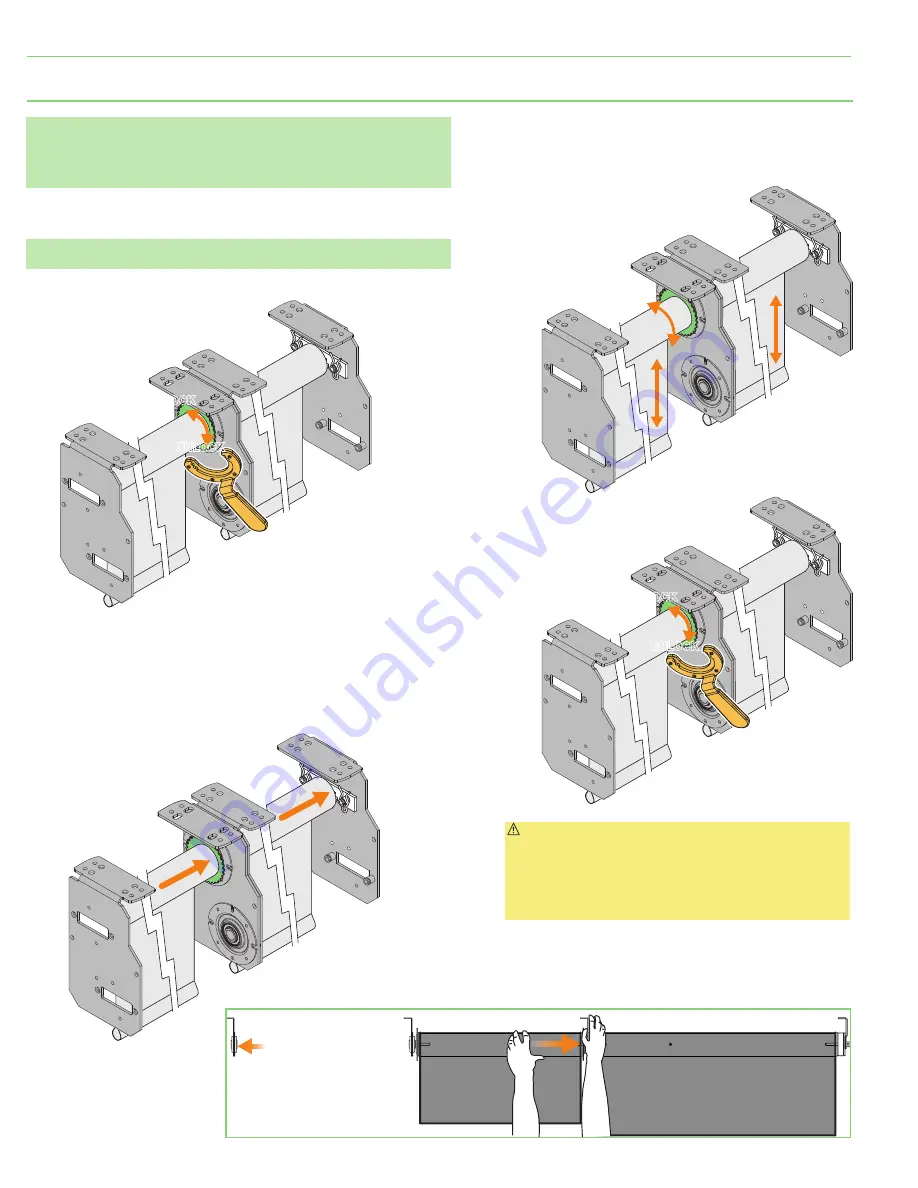

Unlock height adjuster mechanism

(or coupler shaft receiver)

located at the operator-

end of fabric roller assembly being adjusted by rotating the metal ring about ¼

turn counterclockwise when viewing the face of the coupler assembly

(Fig. 10)

.

Please note:

Do not use this procedure to adjust the operator-end assembly. Use the

limits to set the down travel of the operator-end assembly.

5.

Tighten the locking ring by firmly rotating it approximately ¼ turn

clockwise

(reverse of step 1)

(Fig. 13)

.

6.

Operate the unit to check for proper fabric position, tracking, etc.

2.

Push the fabric/roller assembly being adjusted toward the operator-end of the

unit. The fabric/roller assembly will move approximately

3/16

"

(8 mm)

toward the

operator end

(Figs. 11 and 12)

.

3.

Rotate the fabric/roller assembly being adjusted in either direction to raise or

lower the fabric panel

(Figs. 12 and 13)

.

4.

Allow the fabric/roller assembly being adjusted to move back, away from the

operator end of the unit, and check the position of the fabric panels.

Caution:

Ensure the locking ring on the idler-end coupler

assembly is fully tightened following height adjustment. Ensure

you are wearing a heavy glove on the hand you will be using to

grip the locking ring. Tighten the locking ring until it is fully

locked and you cannot rotate it any further. Check to ensure is it

tight and will not work loose. If you cannot tighten by hand, you

may need to use a flat screwdriver or other tool to assist.

Section 6 -

Fabric/Roller Assembly Alignment

(Steps are shown for right-hand operators)

Unlock coupler shaft receiver

by rotating the metal ring about

turn counterclockwise.

LOCK

UNLOCK

Figure 10

Rotate the fabric/roller assembly

being adjusted to adjust

the fabric length.

Figure 12

Tighten the locking ring

by firmly rotating it

approximately 1/4 turn

clockwise.

(Inverse of Step 1)

LOCK

UNLOCK

Figure 13

Push the fabric/roller assembly

approximately

toward

the operator end of the unit.

Figure 11

Figure 14

Operator Panel

Location of next panel

page 8 of 12

Dual Roller Coupled Motorized FlexShades

®

(Large Hardware)