PAS

®

Micro Series

Airline/Short duration respiratory protection equipment with PAS

®

ASV

Instructions for Use

i

3359994 (A3-D-P) Page 3 of 3

Additional inspection and testing may be required in the country of

use to ensure compliance with national regulations.

Notes

O

Dräger recommendations

1. Clean the equipment if it is dirty. If it the equipment has been

exposed to contaminants, disinfect any components that come

into direct and prolonged contact with the skin.

2. These maintenance tasks may only be carried out by Dräger or

trained service personnel. Details of the tests are contained in

the technical manual which is issued to service personnel that

have attended a relevant Dräger maintenance course.

3. For type A check the O-ring on the lung demand valve; and for

type ESA check the outer surface of the male part of the push-

in connector on the lung demand valve. As a guide, lubricant

should be felt on the fingers but not seen. If relubrication is

required, lightly apply Dow Corning

®

Molykote

®

111 (other

lubricants are not tested and may damage the equipment).

5.2

Maintenance tasks

5.2.1

Removing the cylinder

WARNING

High-pressure air release may cause injury to the user or

other personnel near the breathing apparatus. Close the

cylinder valve and fully vent the system before attempting

to disconnect the air cylinder.

1. Close the cylinder valve and press the front button

(Fig 3, Item 3) to fully vent the system.

2. Loosen the cylinder strap.

3. Disconnect the cylinder valve from the pressure reducer.

4. Remove the cylinder. To prevent damage, ensure that the

hand wheel of the pressure reducer remains clear of the

cylinder.

5.2.2

Air cylinder charging

WARNING

Air quality for compressed-air cylinders must conform to

requirements of EN 12021.

●

Refer also to the instructions supplied with the cylinder and the

charging unit for recharging the cylinder.

●

Only charge compressed-air cylinders which:

○

Conform to national standards.

○

Feature the original manufacturer’s test date and test mark.

○

Have not exceeded the test date indicated on the cylinder

by the last testing station.

○

Are not damaged.

●

To prevent ingress of moisture into the cylinder, ensure that the

cylinder valve remains closed until connected to the charging

unit.

●

Recharge to the rated working pressure of the cylinder. Dräger

recommend a charge rate of 27 bar/minute (rapid charging will

increase the temperature resulting in an incomplete charge).

●

To prevent overcharging of the cylinder, Dräger recommend

using a pressure-limiting device on the charging compressor.

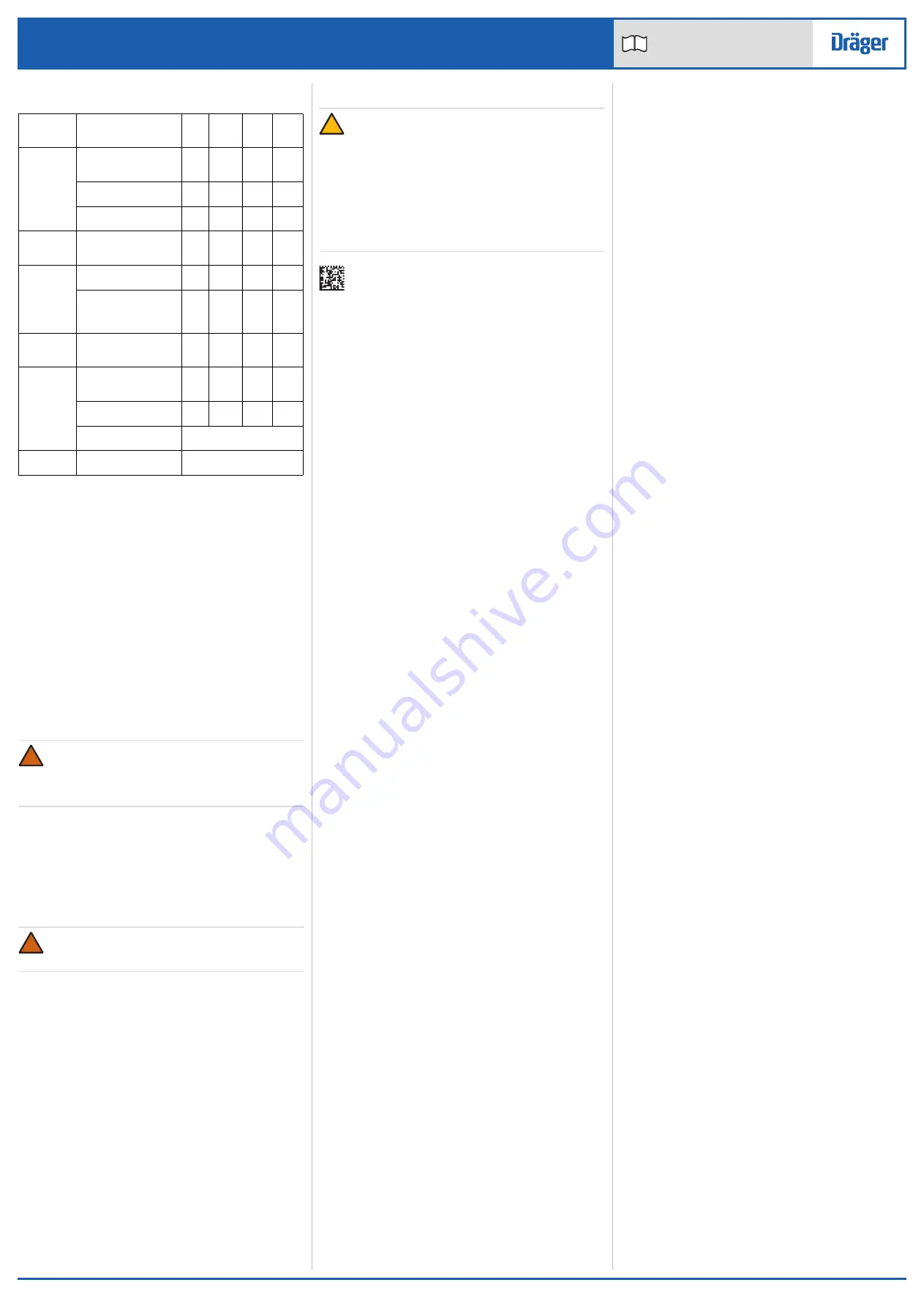

Component/

System

Task

After

use

Every

month

Every

year

Every

six

years

Complete

equipment

Visual inspection

(see Note 1 and

Section 3.1.1)

O

O

Functional test

(see Section 3.1.3)

O

O

Flow and static tests (see

Note 2)

O

Lung

demand

valve O-ring

Check and lubricate if

necessary (see Note 1)

O

Pressure

reducer

Medium-pressure check

(see Note 2)

O

Renew the high-pressure

connector O-ring and

sintered filter (see

Note 2)

O

Pressure

reducer and

PAS

®

ASV

Overhaul – Contact

Dräger for the Repair &

Exchange (REX) service

O

Cylinder

Charge to correct

pressure

(see Section 5.2.2)

O

Check the initial test date

stamped on the cylinder

O

Cylinder pressure test

and recertification

Carry out in line with national

regulations

Cylinder

valve

Basic overhaul

During cylinder pressure test

or on condition

!

!

5.3

Cleaning and disinfecting

CAUTION

Do not exceed 60 °C for drying, and remove components

from the drying facility immediately when dry. Drying time

in a heated dryer must not exceed 30 minutes.

Do not immerse pneumatic or electronic components in

cleaning solutions or water.

If water is trapped and then freezes inside the pneumatic

system of the breathing apparatus (such as the lung

demand valve), operation will be impaired. Prevent any

liquid from entering, and thoroughly dry the breathing

apparatus after cleaning to prevent this from occurring.

For information about suitable cleaning and disinfecting

agents and their specifications refer to document 9100081

on www.draeger.com/IFU.

Refer also to the Instructions for Use for the lung demand valve,

face mask and other associated equipment.

●

Use only clean lint-free cloths

1. Clean the breathing apparatus manually using a cloth

moistened with cleaning solution to remove excess dirt.

2. Apply disinfecting solution to all internal and external surfaces.

3. Rinse all components thoroughly with clean water to remove all

cleaning and disinfecting agents.

4. Dry all components using a dry cloth, in a heated dryer or in air.

5. Contact service personnel or Dräger if disassembly of

pneumatic or electronic components is required.

6

Storage

Store the equipment between -15 °C and +25 °C. Ensure that the

environment is dry, free from dust and dirt, and does not subject

the equipment to wear or damage due to abrasion. Do not store

the equipment in direct sunlight. Note also the following:

●

Extend the shoulder straps, the waist belt and the head

harness straps of the face mask.

●

For hygienic storage, place the face mask in a protective bag

(contact Dräger for supply of a suitable bag).

●

Route rubber hoses in such a way that the bend radius is not

too acute and the hose is not stretched, compressed or

twisted.

●

Fix the apparatus securely to any raised mounting point to

prevent it from falling.

7

Disposal

When required, dispose of the PAS

®

Micro in accordance with

national or local regulations for waste disposal.

8

Technical data

●

High-pressure connector: 200 bar or 300 bar, standard G5/8”

as per EN 144-2.

●

Independent air supply (single user):

○

Airline pressure and flow requirements: pressure 6 to

10 bar, air flow rate at least 550 litres/minute.

Important

note

: do not exceed 10 bar.

○

Airline hose requirements: maximum of 100 m of Dräger

approved hose.

Important note

: no more than four

individual hoses (a maximum of five hose connections) are

permitted in the airline.

●

PAS

®

ASV: whistle activates and switch-over occurs in the

range: 3.5 to 5.5 bar (airline pressure).

●

Pressure reducer: whistle commences in the range:

110 to 100 bar (cylinder pressure).

●

Whistles cease in the range: 1.75 to 0 bar (cylinder pressure).

●

Whistle volume: >90 dBA.

!