REMOVAL, SHARPENING AND RE-INSTALLATION OF CHIPPER KNIFE

HOW TO REMOVE THE KNIFE

•

Stop the engine.

•

Remove both spark plug wires and keep away from spark plugs.

•

Disconnect battery at negative terminal.

•

Remove both access covers from the chipper basic machine.

•

Rotate the chipper disk until the three countersunk screws and nylock nuts attaching the

knife to the flywheel are visible through the access doors.

•

Clean out the heads of the allen screws with an awl or sharp tool.

•

Insert a 3/16” allen wrench into the heads of the screws.

•

Use a ½” socket and ratchet to remove the nylock nuts from the screws.

•

Remove all three allen screws and nuts in this manner.

KNIFE SHARPENING

•

You should never attempt to sharpen the chipper knife (or knives) freehand.

•

It is extremely important that the 45 degree angle be maintained consistently for proper

performance.

•

The chipper knife should be taken to a machine shop for proper sharpening.

•

Excessive heat generated during the sharpening process will damage knives and weaken

the metal.

Be sure the knife is not overheated.

KNIFE INFORMATION

•

The chipper knife should be checked routinely for sharpness.

•

Using a dull knife will decrease performance and cause excessive vibration that will

cause damage to the chipper.

•

How many times a knife can be sharpened is determined by how much material needs to

be taken off to sharpen or to compensate for dents or gouges.

•

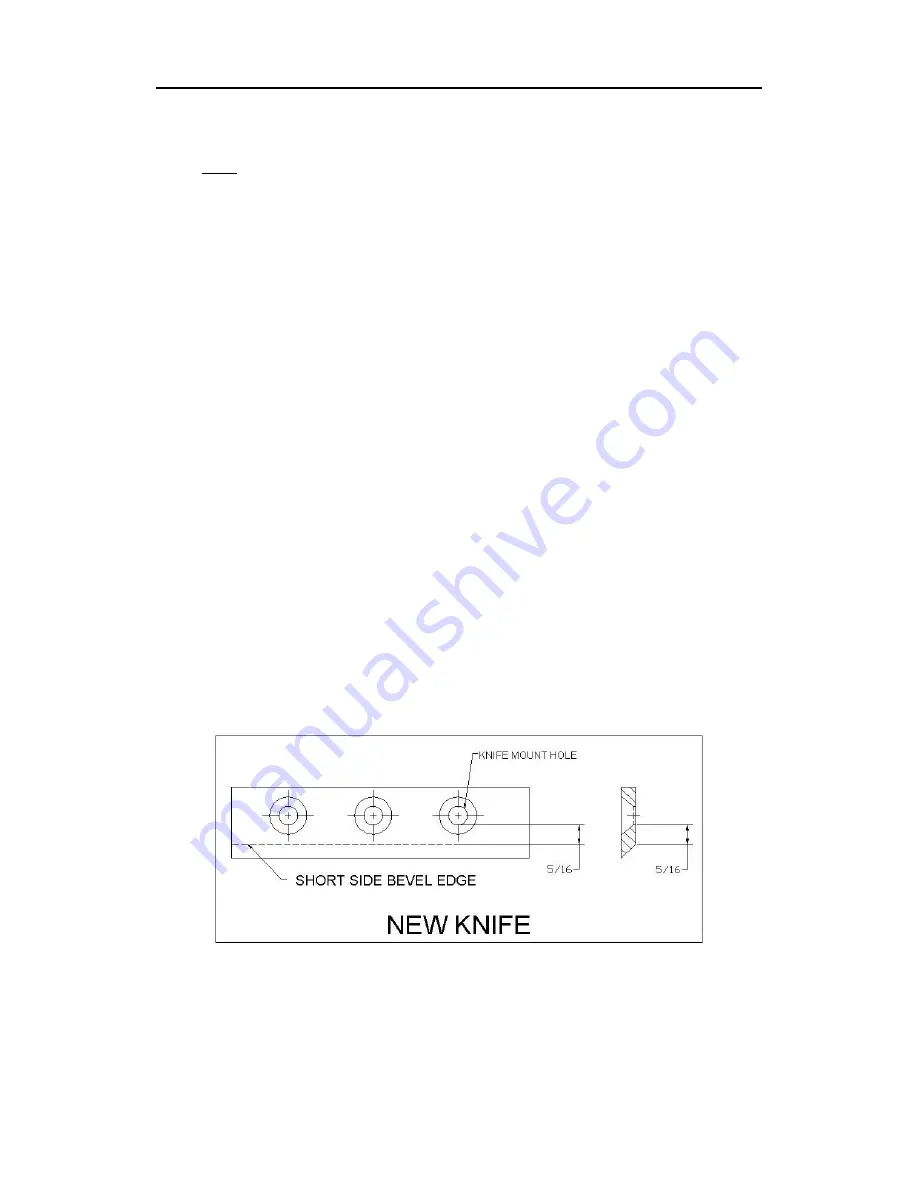

A new chipper knife has 5/16” measurement between the short side bevel edge and the

knife mounting holes. See figure 2.

Figure 2

22

Summary of Contents for TLC18-CHP

Page 4: ...091 0057 091 0059 091 0062 091 0088 091 0093 4...

Page 5: ...091 0256 091 0378 091 0379 091 0380 091 0381 5...

Page 6: ...091 0384 913 0265 6...

Page 31: ...31...

Page 32: ...32...

Page 34: ...34...

Page 35: ...NOTES 35...