3. Connect one output of the

Power Splitter

to the Doric

LED Driver

12 V input, the other to the

Power Extension Cable

.

4. Connect the

Power Extension Cable

to the

Fan Power Adapter 12 V

input.

5. Connect each channel of the LED driver to the input connectors of the

Fan Power Adapter

using M8 cables.

6. Connect

LEDFRJ

to the

Fan Power Adapter

using M8 cables.

7. Connect the 12 V power supply to the wall plug.

8. Ensure the power key and the interlock plug are properly set in place.

9. Apply current and voltage within the limits indicated in table

. On the

Combined LED

models, it is critical not to

block or insert objects into the grids as this could block airflow and reduce cooling efficiency.

10. When not in use, place plastic caps on the connectors for protection and cleanness.

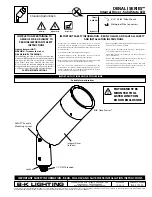

2.2 FC Connector Installation

1. Clean the optical fiber connector before insertion. Use isopropanol and a lint-free wipe.

2. With an FC connector, the connector key must be oriented to enter within the receptacle slot to ensure proper

connection (Fig.

Figure 2.2:

FC connector, Fiber Installation

To reduce the risk of eye injury,

it is sound practice to NOT CONNECT/DISCONNECT OPTICAL

FIBERS when the light source is turned on

.

Chapter 2. Operations Guide

7