4-55

Inspection, Maintenance and Adjustment

Hydraulic Oil Exchange and Suction

Strainer Cleaning

NOTE:

Based on the type of excavating being completed,

the working conditions (extremely hot or dusty) and

the extra front end attachments being used (hydraulic

breaker, etc.), the hydraulic fluid will need to be

changed more frequently.

1.

Position the machine on firm, level ground. Swing upper

structure perpendicular (90°) to tracks. Lower boom and

position bucket on ground as shown in Figure 101.

2.

Set safety lever on "LOCK" position.

3.

Shut down engine.

4.

Release pressurized air from hydraulic tank by lifting

breather cap (1, Figure 104).

Figure 100

ARO1760L

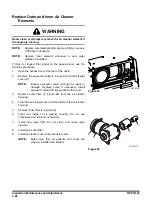

WARNING

The hydraulic oil will be hot after normal machine

operation. Allow the system to cool before attempting to

service any of the hydraulic components.

The hydraulic tank is pressurized. Lift the breather cap to

allow the pressurized air to vent. After the pressure has

been released, it is safe to remove either the fill cap or

service covers.

IMPORTANT

Make sure to clean any dirt or water from the top of the

hydraulic tank, especially around the fill port and filter ports.

Hydraulic oil change interval is 2,000 hours, only when

DOOSAN

Genuine Oil is used. If another brand of oil is

used, guaranteed change interval is 1,000 hours.

Figure 101

FG015805

Summary of Contents for DX700LC

Page 2: ......

Page 72: ...OP001120 Safety 1 66 ...

Page 142: ...OP001121 Operating Controls 2 70 ...

Page 188: ...OP001122 Operation 3 46 ...

Page 197: ...OP001123 4 9 Inspection Maintenance and Adjustment ...

Page 282: ...OP001123 Inspection Maintenance and Adjustment 4 94 ...

Page 298: ...OP000030 Troubleshooting 6 6 ...

Page 301: ...OP001125 7 3 Specification ...

Page 308: ...OP001125 Specification 7 10 ...

Page 314: ...950106 00012E Index 8 6 ...