OP000599

4-33

Inspection, Maintenance and Adjustment

4.

When replacing belts and pulleys, pulley alignment must

be checked with belts tensioned and brackets securely

clamped. A misalignment that can be detected by the

naked eye is detrimental to belt performance.

5.

Do not force the belts into the pulley grooves by prying with

a screwdriver or pry bar. This will damage the belt side

cords which will cause the belts to turn and result in

complete destruction of the belts in operation.

6.

Belts on new machines and replacement belts lose their

tension as they seat into the pulley grooves. Check the

tension of new belts at 50 hour intervals until tension is

stabilized and thereafter, every 250 hours. If the tension

falls below the required minimum, the belt slips damaging

the belts and pulley grooves.

NOTE:

When operating in abrasive conditions, check

tension every 100 hours.

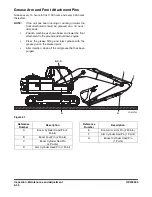

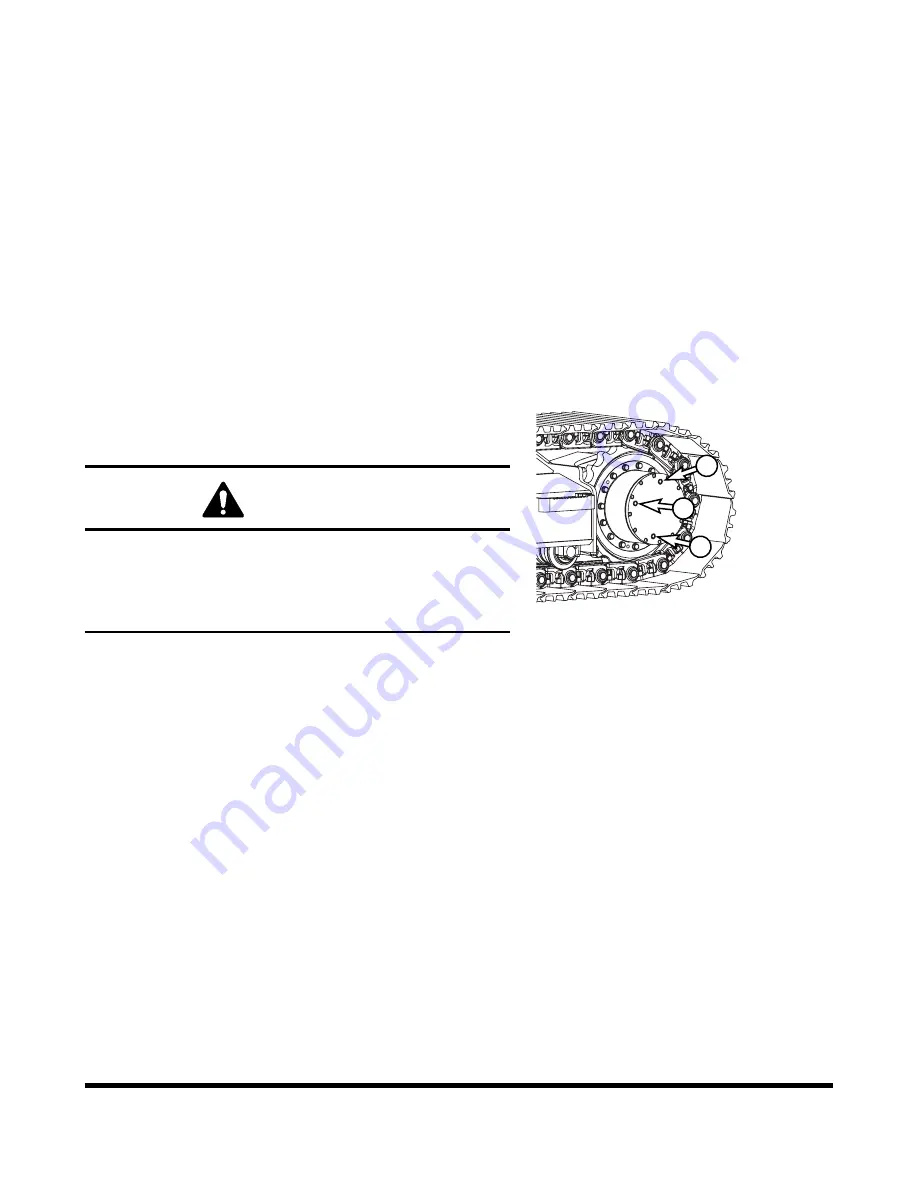

Check Oil Level in Travel Reduction

Device (One on Each Side of Unit)

1.

Make sure that the machine is on firm, level ground.

2.

Rotate the track until ports (1 thru 3, Figure 48) are in their

proper positions as shown.

3.

Loosen fill plug (3, Figure 48) slightly to allow pressurized

air to escape.

4.

Remove oil level plug (1, Figure 48).

5.

Check oil level. The oil should be near the bottom of the

level plug opening.

6.

Add oil through the fill plug (3, Figure 48) opening, if

necessary.

7.

Clean and install oil level and fill plugs (1 and 3, Figure 48).

8.

Repeat this procedure on the other travel reduction device.

Figure 48

2

3

1

FG009568

WARNING!

The gear oil is very hot after the machine has been

operating. Shut all systems down and allow them to cool.

Before fully removing any motor case inspection port plug,

etc., loosen the plug slightly to allow pressurized air to

escape.

Summary of Contents for DX140LC

Page 2: ......

Page 67: ...OP000597 2 3 Operating Controls ...

Page 87: ...OP000597 2 23 Operating Controls ...

Page 122: ...OP000597 Operating Controls 2 58 CD Player Optional AST DIR FG000109 Figure 123 ...

Page 184: ...OP000598 Operation 3 48 ...

Page 193: ...OP000599 4 9 Inspection Maintenance and Adjustment ...

Page 272: ...OP000599 Inspection Maintenance and Adjustment 4 88 ...

Page 278: ...OP000600 Transportation 5 6 ...

Page 284: ...OP000013 Troubleshooting 6 6 ...

Page 292: ...OP000601 Specification 7 8 ...