OP000599

Inspection, Maintenance and Adjustment

4-18

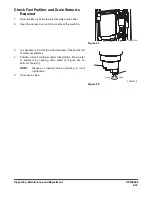

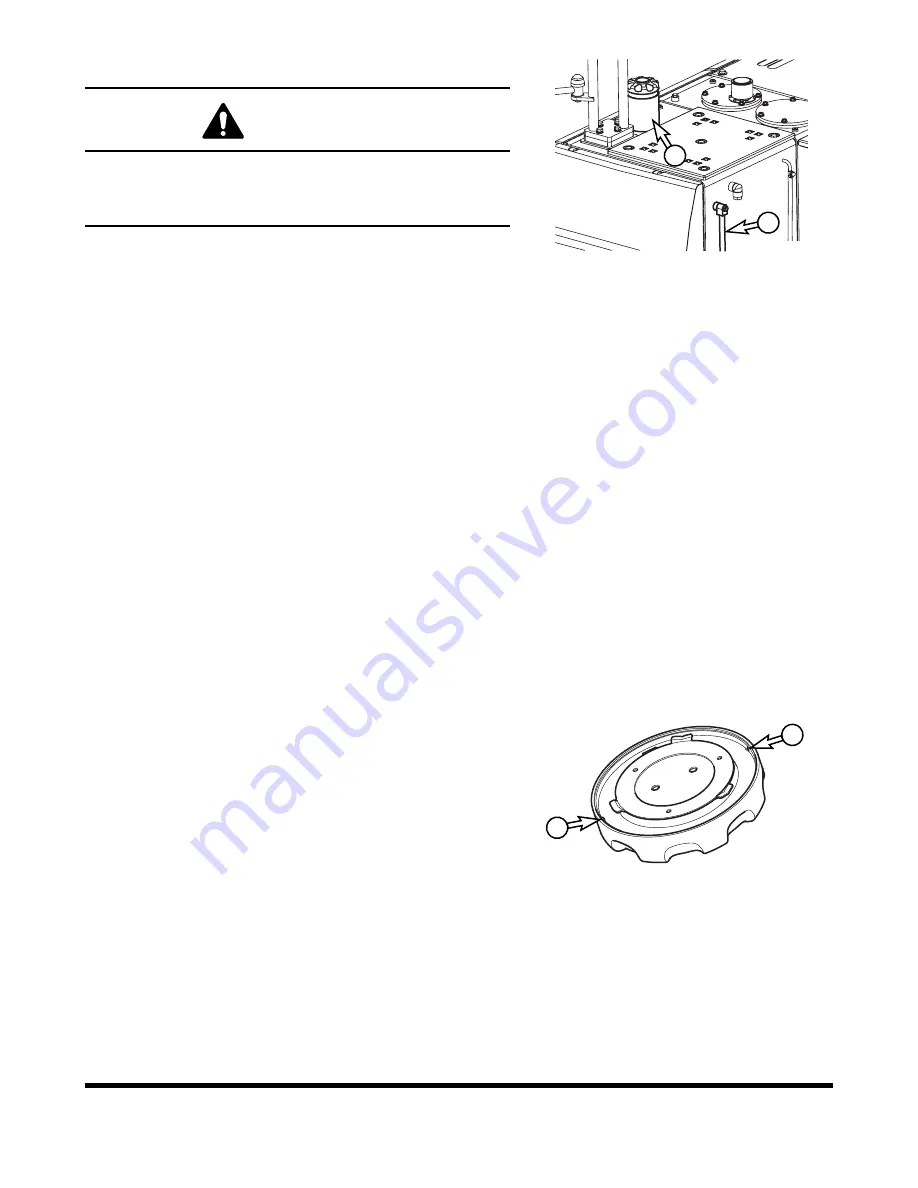

Check Fuel Level

1.

At end of each work day, fill fuel tank. Add fuel through fuel

fill tube (1, Figure 21). When working at a temperature of

0°C (32°F) or higher, use ASTM No. 2-D or its equivalent.

At temperatures below 0°C (32°F) use ASTM No. 1-D or its

equivalent.

2.

Make sure that the fuel fill hose is grounded to the

excavator before fueling begins.

3.

Check the amount of fuel in the tank by observing the fuel

tank sight gauge (2, Figure 21).

NOTE:

See “Fluid Capacities” on page 4-8. for

capacity.

4.

The excavator may be equipped with the optional battery

operated fuel fill pump. The pump assembly is in the

hydraulic pump compartment. Put the suction hose of the

pump into the fuel resupply tank. Turn the switch in the

pump compartment "ON," and the fuel will be pumped into

the excavator fuel tank.

NOTE:

See “Fuel Transfer Pump (Optional)” on

page 4-78, for further information.

5.

Do not overfill the tank.

6.

Securely tighten cap after fueling.

NOTE:

If breather holes (3, Figure 22) in cap are

clogged, a vacuum may form in the tank

preventing proper fuel flow to engine. Keep

holes in fuel cap clean.

Check for Leaks in Fuel System

1.

Perform an inspection of the engine compartment to verify

that the fuel system is not leaking. If any is noted,

determine the source of the leak and repair.

Figure 21

1

2

FG009552

WARNING!

Use extreme safety precautions while refueling to prevent

explosions or fire.

Immediately clean up any split fuel.

Figure 22

FG000317

3

3

Summary of Contents for DX140LC

Page 2: ......

Page 67: ...OP000597 2 3 Operating Controls ...

Page 87: ...OP000597 2 23 Operating Controls ...

Page 122: ...OP000597 Operating Controls 2 58 CD Player Optional AST DIR FG000109 Figure 123 ...

Page 184: ...OP000598 Operation 3 48 ...

Page 193: ...OP000599 4 9 Inspection Maintenance and Adjustment ...

Page 272: ...OP000599 Inspection Maintenance and Adjustment 4 88 ...

Page 278: ...OP000600 Transportation 5 6 ...

Page 284: ...OP000013 Troubleshooting 6 6 ...

Page 292: ...OP000601 Specification 7 8 ...