OP000509

4-65

Inspection, Maintenance and Adjustment

Replace Pipes and Hoses

1.

Replace hoses that carry brake fluid to wheel brakes.

Also replace hoses that carry hydraulic fluid to steering

cylinders.

2.

It is difficult to determine condition of many hoses. The

best way to ensure safe operation and to maintain

maximum performance is to replace hoses on a regular

basis. If any brake or steering hoses become damaged

or appear defective in any way, replace them

immediately despite time interval since their last

replacement.

Bleed Brakes

When brake hoses or brake tubes are replaced, air can be

introduced into brake hydraulic system. Air can cause brakes

to operate intermittently, which is a dangerous condition.

Never operate machine with air in brake hydraulic system. A

spongy feel when pressing brake pedal is a sign that air is

present in brake hydraulic system.

To bleed air out of brake hydraulic system, perform the

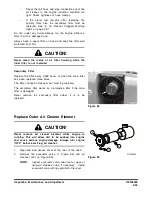

following steps: (Figure 102)

1.

Start engine and place transmission in "NEUTRAL."

2.

Remove rubber cap from bleeder screw on wheel.

3.

Place one end of a plastic hose (2) over bleeder screw

(1). Place other end of hose in a container (3) filled

with brake fluid.

4.

Station one person in operator’s cab, and one person

at bleeder screw on wheel being bled.

5.

Open bleeder screw (1). Then press down on brake

pedal until it rests on floor of cab. Hold pedal down on

floor of cab. Close bleeder screw while pedal is being

held down. After bleeder screw has been closed, allow

brake pedal to return to upright position. Continue to

open bleeder screw and press down pedal as

described in this step, until fluid expelled from bleeder

hose has no air bubbles present.

6.

Securely close bleeder screw (1). Install rubber cap on

bleeder screw.

1

2

3

HLB3018L

Figure 102

Summary of Contents for DL200

Page 2: ......

Page 6: ...K1024537E Table of Contents IV ...

Page 7: ...K1024537E I I Presentation 1Presentation PRESENTATION FG008047 Figure 1 ...

Page 17: ...OP000506 1 5 Safety 1 3 10 12 6 4 11 5 9 8 3 7 10 9 4 6 2 FG008049 Figure 1 ...

Page 60: ...OP000506 Safety 1 48 ...

Page 112: ...OP000507 Operating Controls 2 52 CD Player Optional AST DIR FG000109 Figure 101 ...

Page 122: ...OP000507 Operating Controls 2 62 ...

Page 232: ...OP000509 Inspection Maintenance and Adjustment 4 88 ...

Page 242: ...OP000040 Troubleshooting 6 8 ...

Page 252: ...OP000510 Specification 7 10 ...