P/N 1808922 Rev. C

4

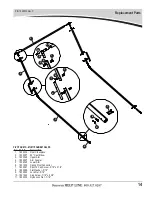

Spring Pivot Installation - Tandem Axle Hydraulic Housing Assembly

STEP 2A

: Use mounting plates, elbows and tubes to fabricate

spring pivot supports for spring assemblies, modifying

components as needed (see next page for necessary

dimensions).

STEP 1:

Determine location for spring assemblies. To locate

center of spring assemblies to support arms to cover

up to a 40-yard container, measure 147" from back of

base assembly. To ensure tarp does not extend past

rear of container, load truck’s largest container onto

truck and center spring assemblies between base

assembly and rear of container.

NOTE:

Fenders on most trucks are not strong enough to

support spring assemblies. Fabricate spring pivot supports

to support weight and torsion of spring assemblies. Supports

must be square and level for system to operate correctly.

IMPORTANT:

Locate spring assemblies as low on truck frame

as possible to allow clearance between roll-off container and

spring assemblies. Top of spring assemblies must be less

than 5" above rollers used to support container. If needed,

pull container onto truck and check for clearance.

Item Part #

Description

1. 1808664 Bridge Mount Spring Assembly -

Passenger Side

2. 1808665 Bridge Mount Spring Assembly -

Driver Side

3. 1808673 Frame Mount Plate - 3" Sq. Tube

4. 1808646 Frame Mount Gusset

5. 1808678 End Cap - 2 1/2" Square Tube

6. 1808679 Spring Pivot Mount Tube

7. 1808675 Spring Pivot Support Elbow

8. 1808672 Spring Pivot Support Tube

H. 1804139 Cap Screw - 3/8" x 3 1/4"

Q. 1800993 Nylon Lock Nut - 3/8"

Y. 1800994 Flat Washer - 3/8"

1

2

3

4

5

8

7

6

H

H

Y

Q

147"

NOTE:

Do not weld directly to truck frame as this can weaken

frame and potentially void warranty. Use mounting plates and

drill 5/8" holes and fasten with grade 5 or better 5/8" bolts,

washers and nuts (not included), or weld components to

structure existing on truck frame.

plate

support

tube

elbow

gusset

mounting

tube