25

DIAGNOSTIC SERVICE MANUAL

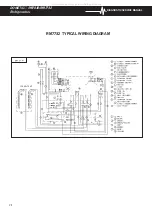

DOMETIC® RM7030/RM7732

Refrigerators

SECTION 9

OTHER

9.1

LEVELING

In an absorption refrigerator system, ammonia is

liquefied in the finned condenser coil at the top of the

refrigerator. The liquid ammonia then flows into the

evaporator (inside the freezer section) and is exposed

to a circulating flow of hydrogen gas, which causes the

ammonia to evaporate, creating a cold condition in the

freezer.

The tubing in the evaporator section is specifically

sloped to provide a continuous movement of liquid

ammonia downward by gravity through this section. If

the refrigerator is operated when it is not level and the

vehicle is not moving, liquid ammonia will accumulate in

sections of the evaporator tubing. This will slow the

circulation of hydrogen and ammonia gas, or in severe

cases, completely block it, resulting in a loss of cooling.

Any time the vehicle is parked for several hours with the

refrigerator operating, the vehicle should be level to

prevent this loss of cooling. The vehicle needs to be

leveled only so it is

comfortable to live in

(no notice-

able sloping of floors or walls).

When the vehicle is moving, the leveling is not critical as

the rolling and pitching motion of the vehicle will pass to

either side of level, keeping the liquid ammonia from

accumulating in the evaporator tubing.

9.2

VENTILATION

Ventilation is one of the requirements for proper cooling

unit operation. The coach vent system must be able to

provide a way to direct the hot air produced by the

action of the cooling unit, out away from the installation

of the refrigerator.

The refrigerator extracts heat from the interior of the

refrigerator cabinet and dissipates the heat out through

the vent system. In a proper installation there should be

as little open space as possible surrounding the sides

and top of the refrigerator to achieve proper air flow. All

potential dead air pockets should be blocked or baffled

to ensure that heat won't be trapped in these spaces

and reduce efficiency.

NOTE

: Refrigerators should be installed in accordance

with appropriate installation instructions received with

the refrigerator.

9.3

AIR LEAKS

Check the gasket on the doors to be sure of a positive

air seal. A simple method to check gaskets is to close

the door on a dollar bill, then pull the dollar bill out. If no

resistance is felt, the gasket is not sealing properly. This

should be done on all four sides of the door. If a gasket

is not sealing properly, first warm the gasket material

with a hair drier.

DO NOT OVERHEAT AS YOU CAN MELT

THE MATERIAL.

Then close the door and the magnetic strip should pull

the gasket to the metal frame. Leave door closed until

the material has cooled. Then recheck for a positive

seal. If a positive seal cannot be achieved, replace the

gasket. Also check that the cooling unit is installed

properly. The cooling unit's foam block, the portion that

surrounds the evaporator coils, must be flush to the

cabinet at the back of the refrigerator and have a

positive seal. If the cooling unit is not installed properly,

remove and install properly.

RM7030:

The refrigerator is secured in the enclosure with six

screws and they must be installed in the following order:

First Two Screws

installed on front base;

Second Two Screws

installed in the top frame;

Third Two Screws

installed in the rear base.

Failure to follow the sequence in securing refrigerator in

enclosure can

cause leakage

between the

frame and

cabinet.

NOTE

: Air

leaks will

cause insuffi-

cient cooling

as well as

rapid forma-

tion of frost.

0" CLEARANCE

FROM SIDE OF

CABINET

PATH OF

AIR FLOW

CLEARANCE

FROM

COMBUSTIBLE

MATERIALS

2ND

1ST

3RD

All manuals and user guides at all-guides.com