24

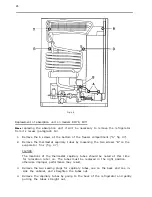

COOLING UN IT REPLACEMENT - RM36C, RM46, RM47, RM66, RM67

Remove the refrigerator from its recess as follows:

1.

2.

3 .

4 .

5.

6.

7.

Check that refrigerator is empty and remove

ice tray.

Turn off gas bottle.

Disconnect gas line to inlet valve

CAUTION: Use a backup wrench to prevent

undue rotation.

Unplug the electric line from the trailer

o u t l e t .

Remove the 4 screws in rear front f fame.

Check for any additional screws which the

vehicle manufacturer may have used to

fasten the refrigerator in place.

Carefully slide the refrigerator straight

out of its recess.

To remove the cooling unit from the cabinet,

proceed as follows:

1.

2.

3 .

4 .

5 .

6 .

Place the refrigerator on a work bench of

suitable height.

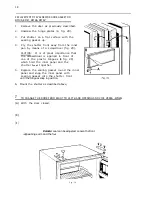

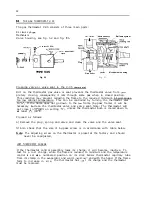

Remove the thermostat capillary tubes by

loosening the two screws “A” on the

evaporator fins (Fig. 41 and fig. 42).

CAUTION: The locations of the thermostat

capillary tubes should be noted at this

time for relocation later on. The tubes

must be placed in the right position,

i

Fig. 41

RM66

RM67

Fig. 42

otherwise, improper performance may result.

Remove the two sealing plugs for capillary

tubes, one on the back and one inside the

cabinet, and straighten the tubes.

Remove the capillary tubes by going to the

back of the refrigerator and gently pulling

the tubes straight out.

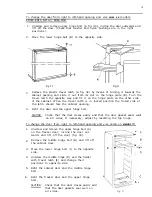

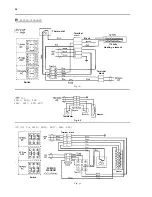

Remove the 4 screws “B” and take away the

evaporator fins “C”. (On RM46, RM47 and

RM66, RM67, 6 screws and 2 screws in the

freezer compartment).

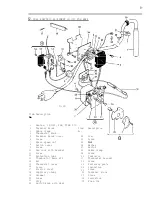

Remove the plastic cover “A” (Fig. 43) by

means of pulling it upwards on the right

hand side which will release it from the

cabinet liner (only on RM36C).

Fig. 43