2

11.01.21 en / 335A

- If standstill is not detected, the braking cycle is interrupted after 20 s.

- The brake current switches off after 0.5 sec standstill detection.

- After activation of the start input mains frequency, phase sequence and

presence of all 3 phases is checked.

- Internal temperature monitoring protects the thyristors. By switching on

or off of the power supply this fault can be reset after the temperature

has dropped.

- To protect the power circuit the current is monitored in L1-T1. If the fixed

settings are exceeded, the device switches off and a failure indication is

displayed by a red LED.

- Monitoring of phases and phase shift protects the motor or the

system. After removing the fault this error can be reset by switching

the power supply on and off.

-

External bimetallic switches or PTC-thermo sensors are used to

monitor motors on thermal overload. (variant /_1_). Overload results in

disconnection of the motor and failure indication via the red error LED.

After a cooling down period for the motor, the failure can be reset reset

switching the power supply OFF and ON again.

Variation of speed is not possible with this device. Without load a softstart

cannot be achieved. It is recommended that the softstart is protected by

superfast semiconductor fuses rated as per the current rating of the softstart

or motor. However, standard line and motor protection is acceptable, but

for high starting frequencies motor winding temperature monitoring is

recommended. The softstarter must not be operated with capacitive load

e.g. power factor compensation on the output.

In respect to safety of persons and plant only qualified staff is allowed to

work on this device.

Green LED: perm. on:

- When auxiliary supply connected or

bypass relay energized

flasher light: - While starting and breaking

Monitoring relay 1

Yellow LED: perm. on:

- When contact 13-14 switched on

Monitoring relay 2

Yellow LED: perm. on:

- When contact 13-24 switched on

Monitoring relay 4

Yellow LED: perm. on:

- When contact 43-44 switched on

Red LED:

steady

flashing:

- Motor current is > 3 x device current

Red LED:

flasher light : - Error

1*

)

:

- Overtemperature on thyristor (internal)

2*

)

:

- Overtemperature on motor or broken wire in

sensor circuit P

1

/ P

2

or bi-metal contact

at sensor circuit P

2

/ P

3

has tripped (ooen)

3*

)

:

- Short circuit on sensor circuit P

1

/ P

2

4*

)

:

- Phase failure

5*

)

:

- Incorrect phase sequence,

exchange connections on L1 and L2

6*

)

:

- Incorrect frequency

7*

)

:

- Incorrect brake circuit

9*

)

:

- Incorrect internal temperature sensor

10*

)

:

- Incorrect RAM

13*

)

:

- Overcurrent

14*

)

:

- Brake current to high

15*

)

:

- Overcurrent at end of ramp up

16*

)

:

- Internal communication error

17*

)

:

- Overcurrent on bridging relay

1-17*

)

= Number of flashing pulses in short sequence

Monitoring Features

Notes

Indicators

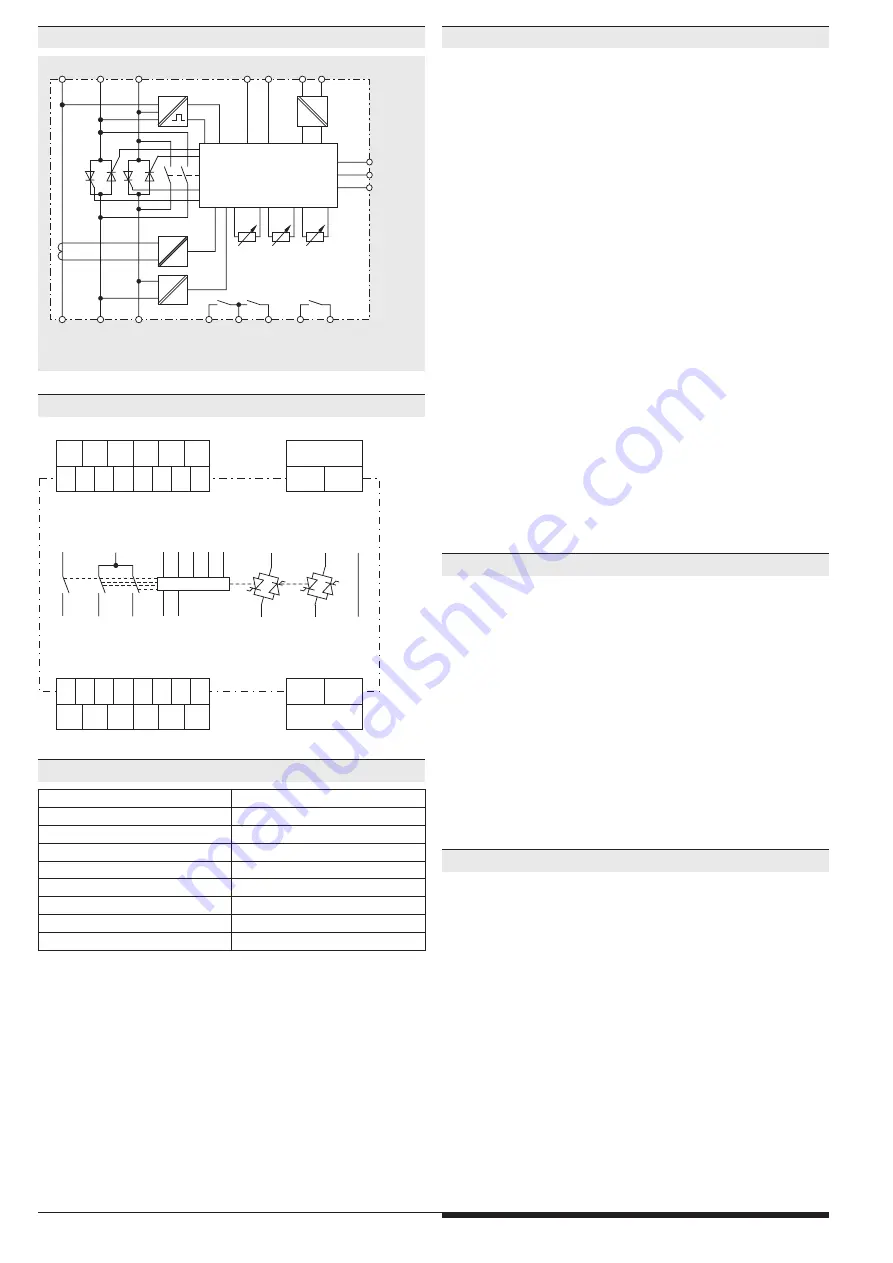

Block Diagram

Circuit Diagram

Terminal designation

Signal description

X1, X2

Start-/Stop-Signal

13, 14

Monitoring relay 1 bridging operation

13, 24

Monitoring relay 2 Ready

43, 44

Monitoring relay4 Standstill

A1(+) , A2

Auxiliary voltage DC 24 V

L1, L2, L3

Phase voltage

T1, T2, T3

Motor connection

P1, P2 , P3

PTC thermal sensor, bi-metal contact

Terminal Connection

M10200_b

13

A1+

X1+

24

A2

X2

L1

T1

L3

T3

14

P3

P2

P1

43

44

L2

T2

L2

43

44

A2

T2

L3

L1

T3

T1

A1 X1 P1 P2 P3

X2

13

24

14

Variante /_1_

L1

L2

L3

T1

T2

T3

M10206_b

M on

t on

I Br

14

43

13

44

24

I

U

U

U

U

P1

variant

/_1_

P2

P3

micro control

A1+ A2

X1+ X2