2

8. Step 8 does not apply to the expansion bearing location, or

the non-expansion bearing location in which integral thrust

collars are used (integral thrust collars are defined as collars

that are machined into the shaft). Use step 8 for split thrust

collars.

Thrust collars in a fixed unit should now be installed.

Remove both clamp screws, and separate both halves of

the split thrust collar (this can require some force). Thrust

collars are cracked, and the split line can be difficult to

identify. Back off set screws to clear inside of collar. Place

one collar half on shaft so that flinger groove is next to liner

base in the nonexpansion (fixed) bearing. Rotate collar half

around shaft and place other collar half in position. Bring

halves together at joint, making sure match at joint is perfect

and insert clamp screws. There should be no offset at collar

face. Tap halves together and tighten clamp screws. Repeat

above operation for opposite end of bearing. Assemble two

collars on one bearing only. Tap collar up to face of liner

allowing a total of .012” to .018” running clearance and

tighten set screws on both collars to recommended torque.

Collar should run parallel to end face of liner within .002”.

Apply oil to mating thrust faces on collar and bearing.

9. Apply oil to bearing surface of liner cap. Locate cap in place

on lower liner making sure oil rings are in their cavities and

are free to rotate. Install and torque liner cap screws given

in Table 2.

NOTE: If liner cap does not seem to fit properly, ensure

match marks are aligned and try again.

These Sleevoil liners have match marks permanently

stamped at the joint near one end. These match marks

permanently ensure parts stay paired and critical orientation

of assemblies is maintained.

10. Tighten housing base to pedestal. Torque bolts to value

given in Table 2.

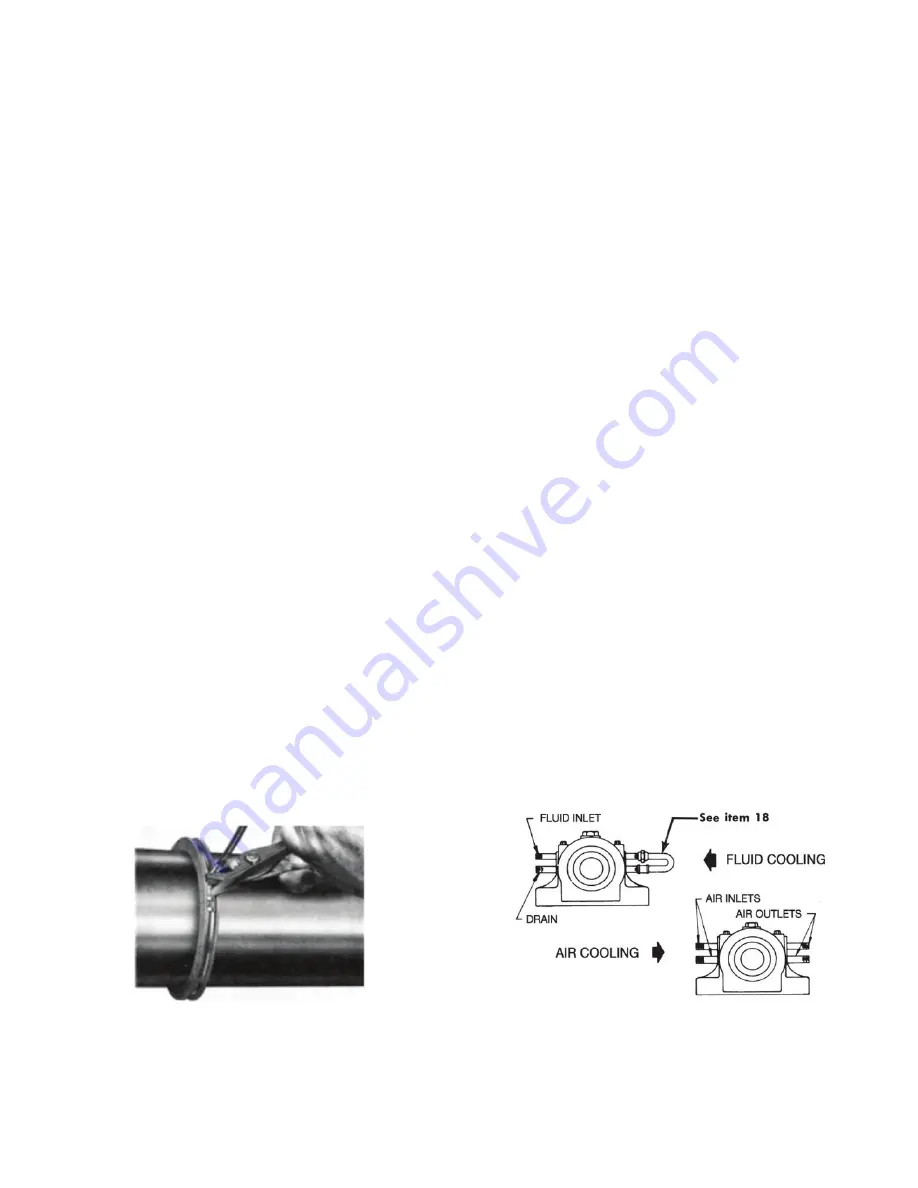

11. Thread dust seal and seal retainer into groove at end of

housing base and around shaft. Slide free end of seal retainer

thru clasp and pull tightly. Hold clasp with screwdriver and

pull free end of retainer as tightly as possible with pliers.

After tightening, it should be difficult to move seal from side

to side. Cut off excess material.

Dust Seals have been upgraded from a cork compound to

HNBR (2014). Cork compound seals have been discontinued.

Use HNBR Dust Seals.

Aluminum seals, when specified for the application by the

OEM, are packaged separately. When using aluminum

seals, discard standard seals and seal retainers packaged

with the housing. To install aluminum seals, wrap the O-ring

(rubber cord), around the shaft in the seal area and cut it

to fit the shaft. Disassemble one seal and place one half

on shaft. Locate O-ring in seal groove and rotate seal half

around shaft into housing base groove. For most effective

sealing the ends of the O-ring must meet. Cementing ends

together is recommended. Install other half of seal and

tighten screws. Install second seal in same manner.

If using End Closure, install neoprene disc(s) at this time.

Consult construction drawing for type of seal recommended.

12. Sleevoil housing gaskets have been replaced by 515 Gasket

Eliminator. Apply gasket eliminator to Sleevoil housing base

along outer contour of joint.

NOTE: Special care should be taken at grommet area.

Cap Loaded Bearings:

With shaft held down (Do not over-

tighten shaft hold-down as this can misalign the bearing)

and plunger screw completely loose, tighten cap bolts to

value shown in Table 2. Tighten plunger screw to torque

value in Table 2 with shaft held down. Mark position of

plunger screw. Loosen plunger screw one complete turn,

then slightly loosen shaft hold down. Tighten plunger screw

to the mark, tighten plunger screw locknut and remove shaft

hold down.

NOTE: Do not tighten plunger screw on accompanying

base loaded bearing until cap loaded bearing has been

installed and hold down removed.

Base Loaded Bearings:

Back off plunger screw completely

and locate housing cap on base taking care not to damage

dust seals or gasket material. Tighten housing bolts to

torque value in Table 2. To reduce chances for leakage a

non-hardening sealant may be used under cap bolts. The

plunger screw must be loose until the housing bolts have

been tightened. Tighten plunger screw to value given

in Table 2. These Sleevoil housings have match marks

permanently stamped near the joint area. These match

marks permanently ensure parts stay paired and critical

orientation of assemblies is maintained.

NOTE: Check and re-torque plunger screw to the

specified torque after 24 hours of initial start-up and

then check & re-torque periodically as required.

13. Plain Liner

: When using a Plain Liner (without coolant

pipes), install grommet and grommet plate over openings in

the sides of the housing. To reduce chances for oil leakage,

a non-hardening sealant may be used. Ensure pipe plugs

are installed in liner.

Externally Cooled Liner:

For XC (Water Cooled Liners with

coolant pipes), punch out 2 holes in each neoprene grommet

to match correct coolant pipe size in liner. Install grommet

and grommet plate over pipes and tighten screws.

Apply

a non-hardening sealant (not supplied) on the housing

grommet area and between the grommet and grommet

plate, and around coolant pipes.