ZTR 501 - PARTS LIST

PART# DESCRIPTION

1657

Spring - Belt Idler

1668

Drive Pulley

1675

Clutch Anchor

1682

L-Rod

1701

Wheel/Deck Hub Bearing

1702

Locking Collar

1712

Battery Strap

1714

T-Box Drive Belt

1715

Rear Wheel & Tire

1732

Pulley - T-Box

1733

Pulley - T-Box Drive

1734

Pulley Hydrostat

1739

Hydrostat Idler Bracket

1742

Bumper

1743

Hydrostat Flat Idler Pulley HO

1744

Hydrostat Drive Belt

1745

Pulley

2128

Sleeve

2414

Spring

2460

Parking Brake Decal

2823

Oil Drain Assembly

3005

5/16"-18 UNC Hex Nut

3006

5/16"-18 x 1 1/4" HH Bolt Gr 5

3007

1/4"-20 UNC Hex Nut

3008

1/4" ID x 3/4" 00 Flat Washer

3009

5/16"-18 UNC x 1 3/4" HH Bolt Gr 5

3014

l/4"-20 UNC x 3/4" HH Bolt Gr 5

3019

5/16" Helical Lock Washer

3020

5/16" Std Flat Washer

3023

1/4" Helical Lock Washer

3029

Front Grommet

3031

5/16"-18 UNC Acorn Nut

3033

1/2" SAE Flat Washer

3035

1/2"-13 UNC Hex Jam Lock Nut

3037

3/8"-24 UNF x I 1/4" HH Bolt Gr 5

3047

3/8"-24 UNF Hex Lock Nut

3048

3/8"-16 UNC x 1 i/2" HH Bolt

3052

3/32" Dia x 1" Cotter P1n

3054

3/16" Dia x 1" Roll P1n

3056

5/16" Fender Washer

3057

3/8" Std Flat Washer

3061

5/16"-18 UNC 1 3/4" Soc Set Screw

3065

3/8" Helical Lock Washer

3066

3/16" Std Flat Washer

3072

1/8" x 1 3/4" Hatr Pin Cotter

3074

5/16"-24 UNF Hex Jam Nut

3081

16-32 UNC Hex Nut

3082

16 Lock Washer

3087

5/16"-18 UNC x 3/4" HH Bolt Sr S

3088

l/4"-20 x 1" HH Bolt Gr 5

3090

l/4"-20 x 1 1/4" HH Bolt Gr 5

3091

l/4"-20 UNF Hex Lug Nut

3093

5/16"-18 UNC x 1" HH Bolt Gr 5

3101

7/16" Helical Lock Washer

3106

1/4" x 1" Spirol P1n

3107

1/4" x 1 1/2" Spiral Pin

3118

Disc Spring

3133

#8-32 x 1 1/2" TR 3 Screw

3134

l/4"-28 x 1/4" Soc Set Screw

3145

#6 Std Flat Washer

3151

16-32 UNC x 1/2" Rd Hd Screw

3161

5/16"-24 UNF LH Thread

3163

1/2" Int Tooth Lock Washer

3169

3/8"-16 x 1" HH Bolt Gr 5

3174

l/2"-13 x 1" HH Bolt

PART# DESCRIPTION

3180

l/4"-2Q Hex Locknut

3182

Flip Lock Bushing

3184

5/l6"-18 x 1 1/4" Pan Hd Phillips Screw

3185

Washer

3186

#12-24 x 3/4" Drill & Tap Screw

3187

#10-32 Hex Nut

3188

#10 Ext Tooth Lock Washer

3193

Washer .43 x 1.38 x .25

3194

Face Nut 5/8"-32

3195

Face Nut l/2"-27

3196

Face Nut 7/16"-28

3198

l/4"-20 Wing Nut w/Nylok

3204

1/4"-20 Hex Nut w/Nylok

3205

5/16"-18 Hex Nut w/Nylok

3206

3/8"-16 Hex Nut w/Nylok

3208

#10-24 Hex Nut w/Nylok

3220

7/16"-20 x 2 3/4" HH Bolt Gr 5

3224

5/8"-18 x 3/4" HH Bolt w/Nylok Gr 5

3225

3/8"-16 x 2 1/4" HH Bolt

3228

5/B"-11 x 6 1/4" Carriage Bolt

3229

Washer

3231

9/16" Std Flatwasher

3233

Battery Hold Down Bolt

3235

#10-24 x 5/8" Phillips Pan Hd Screw

3243

5/16"-18 x 3 1/4" HH Bolt Gr 5

3245

3/8"-16 Thin Profile Nylok Nut

3247

#6-20 x 1/2" Phillips Pan Hd Screw

3248

5/16" ID x 1/8" Thick Washer

3249

5/8" Int Tooth Lock Washer

3256

Snap Ring

3257

7/16" Int Tooth Lock Washer

3258

5/16"-18 x 4 1/2" HH Bolt Gr 8

3259

5/16"-18 x 5" HH Bolt Gr 8

3260

1/4”-20 x 1/2" HH Bolt Gr 5

3262

3/4”-10 Thin Profile Nylok Nut

3263

5/8”--11 Thin Profile Nylok Nut

3264

5/I6" Disc Spring HD

3265

#10-24 x 3/4" Truss Hd Phillips Screw

3266

1/4” Int Tooth Lockwasher (Not Shown)

3267

5/16"-18 x 1 3/8" HH Bolt Gr 5

3268

3/8"-24 x 1 1/4" HH Bolt Gr 8 w/Nylok

3269

5/16"-18 x 1" Soc HB

3270

5/16"-18 x 3" Soc HB

3271

1"-14 Thin Profile Nylok Nut

3300

Foam Pad

3511

Adhesive Bumper Pad

3521

Engaging Cam Mount Bushing

3531

Decal - OPERATING INSTRUCTIONS

3S36

Decal - DANGER

3552

Tank Mount Bracket - Long

3553

Tank Mount Bracket - Short

3554

Fuel Cap/Guage

3558.

2 Gal Tank w/Cap-Gauge

3578

Nylon Bushing

3585

Decal - CUTTING HEIGHT

3589

Spacer (Electic Clutch)

3590

Key 1/4" Sq x 1/2"

3599

Iso Mount Assembly

3600

Rebound Mount

3601

Load Mount

3602

Spacer Tube

3603

Iso Mount Insert

3617

Decal - DIXON

3635

Tee-Fuel Line

3644

Fuel Line 7 1/2"

Page 29

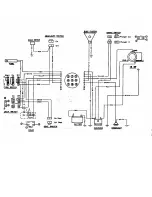

Summary of Contents for ZTR 501

Page 1: ......

Page 20: ... 1 HYDROSTAT MOUNTING BOLTS 2 THREADED ADJUSTERS TO TENSION CHAINS Page 17 ...

Page 21: ... 1 ADJUSTMENT POINTS FOR T BOX BELT TENSION Page 18 ...

Page 22: ... 1 Forward lever stop adjustment Page 19 ...

Page 28: ...Illustration Mower Deck Assembly 50 Model 501 ...

Page 29: ...Illustration Body Assembly Model 501 ...

Page 30: ...Illustration Transmission Assembly Model 501 ...

Page 31: ...Illustration Chassis Assembly Model 501 ...

Page 35: ......