English

-

53

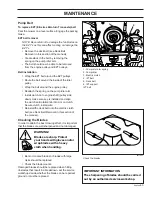

7.

Drain old oil filters of all free flowing oil prior

to disposal. Place used oil in appropriate

containers and dispose of it in accordance

with laws in your area.

8.

Remove the top port plug (see illustration)

from the left side and right side of the

transaxles prior to filling with oil. This will

allow the transaxles to vent during oil fill.

9.

Remove the cap from the transaxles’

expansion tank located on the vehicle

frame.

10. Fill with 20W50 motor oil until oil just

appears at the bottom of each transaxles’

top port (approximately 2 quarts per

transaxle, 4 quarts total). Install the top port

lug into each transaxle as the oil level

reaches this port.

11. Install and torque the top port plugs to 180

in./lbs.

12. Continue to fill the transaxles through the

expansion tank until the “Full Cold” line is

reached (this will take approximately 23

additional ounces).

13. Re-install the expansion tank cap by hand.

Be careful to not overtighten.

14. Proceed to the purge procedure.

1. Filter

2. Top Port Plug

3. Filter Guard

4. Screws

Changing the oil filter

8019-010

1

3

4

2

1

3

2

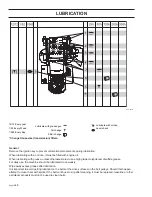

Expansion Tank

1. Expansion Tank

2. Cap

3. Transaxles

8019-012

LUBRICATION