10

5. GETTING READY TO PROFILE

A.

Place of installation

The DIPRO P4600 profiling machine can be used both in a workshop and on site.

Do not expose your machine to the effects of weather

B.

Power

The power supply is directly on the 220 V, 50 Hz network as standard single phase. (References 084746)

Operation on a 110V network requires the purchase of a specific model. (References 084745)

This machine must be supplied by a transformer with the following specification:

min 3 kVA (1650 VA Continuous)

Very important: the electrical line intended to supply the machine must comply

with the standards in force and in particular be protected by a 30 mA differential

circuit breaker

C.

SPACE NEEDED

If working from a coil, the coil must be positioned at least 2 meters from the guides of the profiling machine. For the direction of

insertion of the sheet into the machine (marking on the upper or lower face), you must refer to the suppliers’ recommendations. It

must be ensured that the metal strip is aligned with the entry of the machine and that no constraint disturbs its unrolling.

Do not forget to service your machine (see "Maintenance" on pages 15).

Depending on the material, deformations may occur, which are not caused by the roll-forming but by the

improper installation of the profiling machine.

It is recommended to install a conveyor at the exit of the profiling machine to receive the trays.

Keep your workspace tidy:

A messy workspace causes accidents and reduces your freedom of movement.

D.

Handling of consumables

The metal sheets should not be profiled at too low a temperature (

no less than 7°C for zinc

).

EN

G

2m

EN

G

Summary of Contents for 084745

Page 1: ...EN G EN G DIPRO P4600 Standing seam profiling machine Ref 220V 084746 Ref 110V 084745 EN G ...

Page 2: ...2 ...

Page 4: ...4 ...

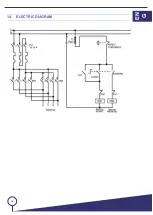

Page 18: ...18 14 ELECTRIC DIAGRAM EN G ...

Page 20: ...20 ...