FUJIFILM Dimatix, Inc. Confidential Information

Doc. # PM000040 Rev. 01

March 26, 2008

Chapter

10

Print Quality Troubleshooting

Printhead jetting issues and subsequent print quality issues typically fall into four main

categories. This section shows the most likely causes, the resulting print artifact and

corrective action that can be taken to mitigate the effects.

1.0

Misdirected Nozzles

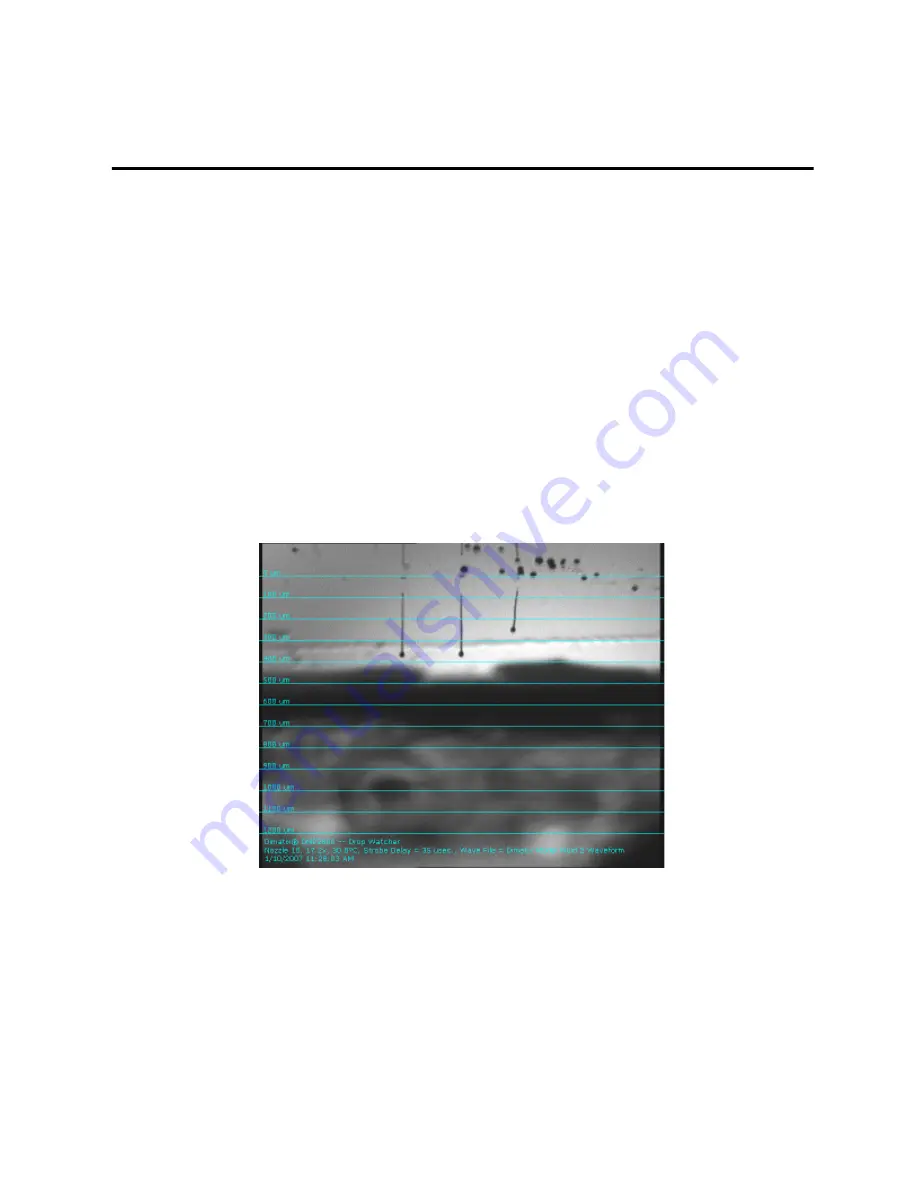

Misdirected nozzles refers to drops that are traveling off axis from left to right, or more

difficult to resolve is front to back. The following figure illustrates a jet ejection off axis in

the drop watcher.

Figure 10 - 1 Jets firing off axis

The primary causes of misdirected nozzles are contamination at or on the nozzle plate and

or air inside the nozzle descender. Contamination is typically a static condition, meaning

that the drop consistently jets to the side in spite of repeated cleaning cycles. This

indicates that debris is lodged just inside the nozzle and is forcing the drop to eject at an

angle.