16

5.

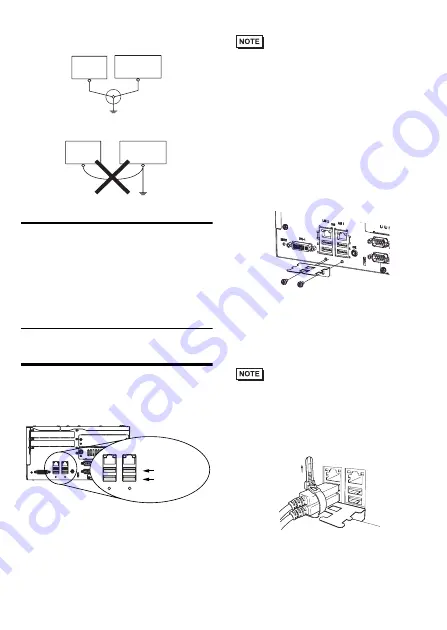

Input/Output Signal Line Cautions

• All PL Input and Output signal lines must

be separated from all operating circuit

(power) cables.

• If this is not possible, use a shielded cable

and ground the shield.

• To improve noise immunity, it is recommended

to attach a ferrite core to the power cord.

To prevent the USB cable

from coming off

Attaching the USB Cable Clamp

(1) Place the PL unit face-down on a flat sur-

face as shown below. Your PL unit has

four USB connectors.

• When using two or more USB ports, be sure

to first connect one USB cable to the lower

USB connector, and then connect the sec-

ond USB cable to the upper USB connector.

• When using only one of the USB ports, be

sure to use the lower USB connector. This

allows you to securely clamp the USB

cable in the cable clamp.

• The USB cable clamp is not compatible

with the USB connector on the front face.

(2) Fix the USB holder with two screws.

The torque required to tighten these

screws is 0.5 to 0.6 N•m.

(3) As the figure shows, pass the USB Cable

Clamp’s band around the depressed sur-

face of the holder, twist the USB Cable

Clamp’s band around the USB cable, pull

the band in the direction of the arrow, and

then fasten the band using the clamp.

• Be sure the clamp is securely holding the

USB cable’s plug and collar.

• Be sure the clamp is positioned as shown

below, with the clamp pointing upwards - not to

the side. This is to keep the clamp from interfer-

ing with nearby connectors and their cables.

Other

Equipment

Common Grounding (OK)

PL unit

Other

Equipment

Common Grounding

(Not OK)

PL unit

1

2

4

3

USB

LAN1

LAN2

1

2

4

3

USB

LAN1

LAN2

SPK

DV1-I

RESET

Lower USB

Interface

Upper USB

Interface

Summary of Contents for APL3600-TA

Page 18: ...18 ...