Operation

Customization process

1.

Open the safe door and close the bolt work (by turning the locking/release lever clockwise as far as

possible).

2.

With the safe door open

, turn the valid key counterclockwise as far as possible (closing).

3.

Remove the key.

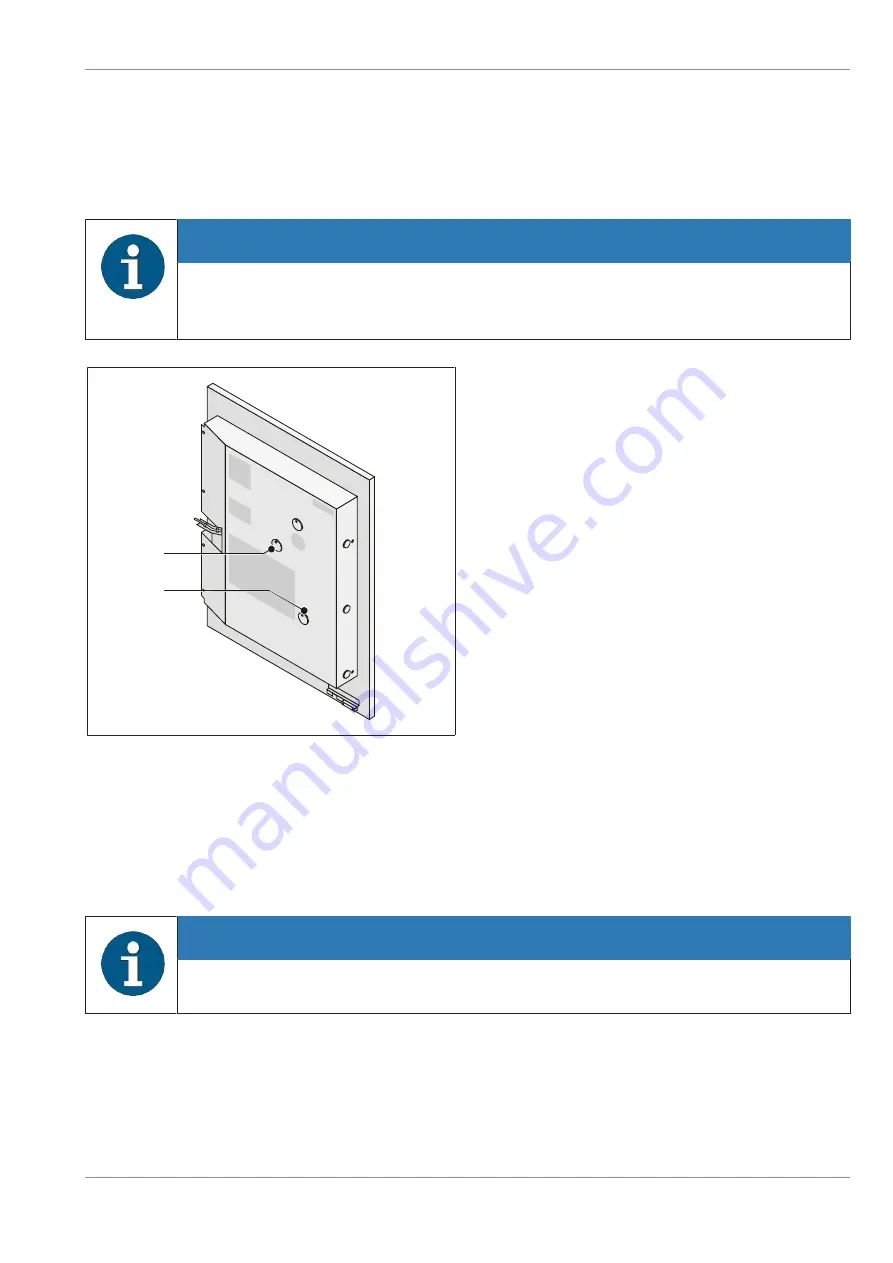

NOTE

The position of the service opening on the inside of the safe door depends on the safe

type used. The illustration shows possible locations (1) or (2) of the sealing plug or the

flap.

1

2

1

2

4.

On the inside of the safe door either remove

the sealing plug of the service opening or

push the flap of the service opening aside.

5.

Press the pushbutton behind the sealing plug or the flap and keep it pressed.

6.

Insert the old key and turn it clockwise as far as possible (opening; approx. 180 degrees).

7.

Release the pushbutton and remove the key (without turning the key again!).

8.

Insert the new key and turn it counterclockwise as far as possible (closing; approx. 180 degrees).

9.

Remove the key.

The lock is now set to the new key.

NOTE

Before you close the door, check at least three times that the lock works correctly with the

new key.

Copyright © 2021, Diebold Nixdorf

01750340329 E

4-10