7

COBRA-H-DLC 09/2003

Daily

Monthly

Yearly

P

M

U

P

&

S

E

N

I

L

H

S

U

L

F

X

R

E

T

L

I

F

T

A

O

L

F

M

U

U

C

A

V

N

A

E

L

C

X

R

E

T

L

I

F

N

O

I

T

U

L

O

S

N

A

E

L

C

X

S

Y

A

W

R

I

A

T

E

L

N

I

K

C

E

H

C

X

E

N

I

H

C

A

M

E

L

A

C

S

E

D

X

S

E

H

S

U

R

B

R

O

T

O

M

M

U

U

C

A

V

K

C

E

H

C

X

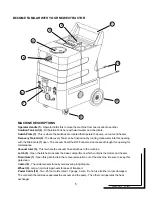

MAINTENANCE

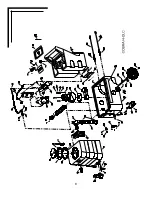

TROUBLESHOOTING

CHECK THIS

Solution tank is empty

Clogged spray tip

Pump not running

Valve on tool not operating

Solution path is clogged. Pump only runs when spraying occurs

Solution tank may be empty, or nearly empty

No power to pump. Test the switch. Test the pump motor.

Partially clogged solution path (hose, heater, tool)

Worn pressure switch in pump. Adjust pressure sensor in pump head.

Debris plugging cleaning tool or vacuum hose

Drain gate is not completely closed, or seals are damaged

Internal vacuum hose is cracked

Recovery tank lid is not closed, is cracked or gasket is damaged

Recovery tank is warpped or cracked

Debris impeding air movement on vac motor impellors

No power to motor. Test the switch. Test the vacuum motor.

Trying to spray too long. Try spraying for 12 -15 seconds per cycle

Heat exchanger needs to be flushed

Wrong tool being used. Too much water passing through

Longer hose, or larger diameter hose, than standard

Heat switch is off

No power in the wall outlet — check to see if breaker has tripped

No power to heat switch — check power cord for ‘opens’

No power out of heat switch. Check power at Bi-metalic switch

Follow troubleshooting steps to isolate the problem. Call your distributor.

IF PROBLEM OCCURS

NO SPRAY

PUMP

DOESN’T

RUN

PUMP

PULSATES

LOW

SUCTION

NO SUCTION

LOW

HEAT

NO

HEAT

If you are unable to diagnose the problem, contact the company from which you purchased your Cobra-H-DLC

Summary of Contents for COBRA-H-DLC

Page 1: ...1 COBRA H DLC 09 2003 COBRA H DLC OPERATOR S MANUAL ...

Page 8: ...8 ...