DUO-100 v2.4 (04/2021)

Page 18

Operation

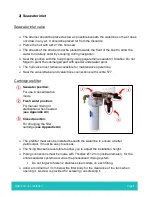

Membranes are delicate components

Reverse osmosis membranes must be carefully maintained as they are the most sensitive

parts of your system. Follow the instructions given to avoid damaging them and voiding the

warranty. The nominal production capacity of the watermaker is given for a temperature of

25°C for seawater and depend on the salinity of the seawater in your navigation area. Each

degree below this given temperature decreases the flow rate by 2.5 to 5%.

Extremes temperatures

The membranes should not be exposed to temperatures below

0°C

. Overpressure, caused

by expansion resulting from freezing, can rupture the membranes and prevent the salt from

being filtered out.

The membranes must not be exposed to temperatures above

60°C

, as high temperatures

may also prevent salt from being removed.

Drying out of the membranes

After the first use, the membranes should be kept immersed in liquid, either in treated

seawater, in a mix of fresh water and sterilizing solution or, temporarily, in fresh water (see

Sterilization methods,

Appendix A4

).

Recommendations for use

The different quality and salinity level of seawater influence the yield of the membranes.

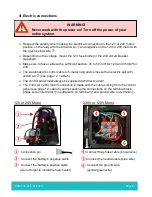

WARNING!

Do not use this system in areas where the water is muddy or

polluted and at the mouth of rivers or brackish water. This will

prevent clogging the prefilter and damaging the membranes.