4

ADDITIONAL SAFETY RULES FOR WOOD SHAPERS

1.

WARNING: DO NOT OPERATE YOUR WOOD

SHAPER UNTIL IT IS COMPLETELY ASSEMBLED AND

INSTALLED ACCORDING TO THE INSTRUCTIONS.

2.

IF YOU ARE NOT

thoroughly familiar with the opera-

tion of Wood Shapers, obtain advice from your super-

visor, instructor or other qualified person.

3.

MAKE SURE

wiring codes and recommended elec-

trical connections are followed and that machine is

properly grounded.

4.

NEVER

turn the shaper “ON” before clearing the

table of all objects (tools, scraps of wood, etc.).

5.

DO NOT

process materials less than 12 in length or

4 in width without special supporting fixtures. Use push

sticks, featherboards or holddowns whenever possible.

6.

ALWAYS

use a miter gage and clamp attachment

when edge shaping work less than 6 wide. The fence

should be removed during this operation.

7.

AVOID

awkward hand positions where a sudden slip

could allow your hand to contact the cutter.

8.

KEEP

hands away from cutting tool.

9.

NEVER

run the stock between the fence and the

cutter.

10.

DO NOT

feed material that is warped, contains knots

or is embedded with foreign objects, such as nails or

staples.

11.

NEVER

start the shaper with the stock in contact

with the cutter.

12.

NEVER

reach under the table while the machine is

running.

13.

NEVER

perform layout, assembly or set-up work on

the table while the shaper is operating.

14.

KEEP

cutters sharp and free from rust and pitch.

15.

THE FENCE

halves should be adjusted so that the

cutter opening is never more than is required to clear the

cutter.

16.

ALWAYS

lock fence hardware after making fence

adjustments.

17.

MAKE CERTAIN

cutters are properly secured before

starting machine.

18.

DO NOT

perform any operation freehand.

ALWAYS

use fence for straight shaping; miter gage for edge shap-

ing; and starting pin and rub collars for curve shaping.

19.

ALWAYS

keep front motor access panel closed

while operating shaper.

20.

ALWAYS

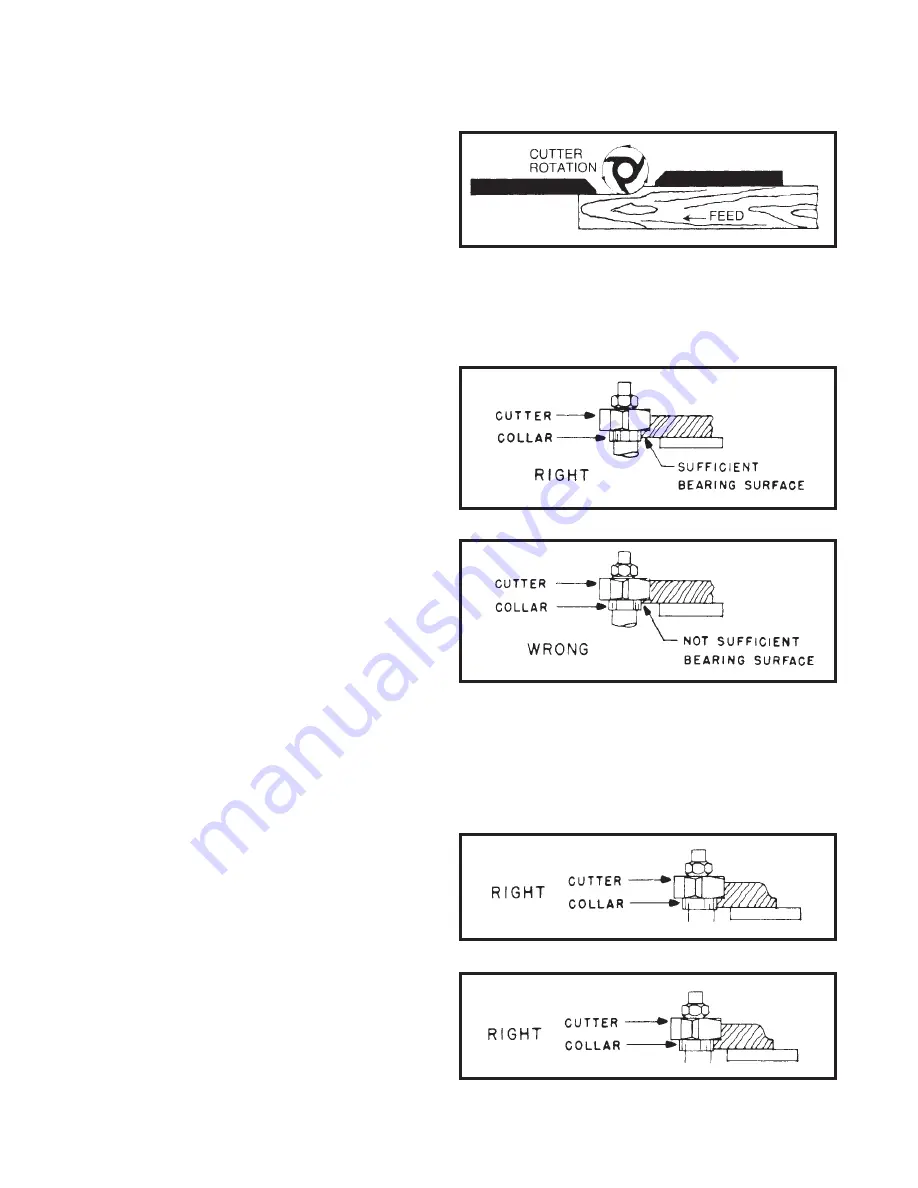

feed against the cutter rotation, as shown

in Fig. A.

21.

WHEN SHAPING

with collars and starting pin, the

collar

MUST

have sufficient bearing surface, as shown in

Fig. B. Fig. C, illustrates the wrong way for this operation

as the collar

DOES NOT

have sufficient bearing surface.

Fig. A

Fig. B

Fig. C

22.

WHEN SHAPING

with collars and starting pin, the

work must be fairly heavy in proportion to the cut being

made as shown in Fig. D.

UNDER NO CIRCUMSTANCES

should short work of light body be shaped against the

collars as shown in Fig. E.

Fig. D

Fig. E