12

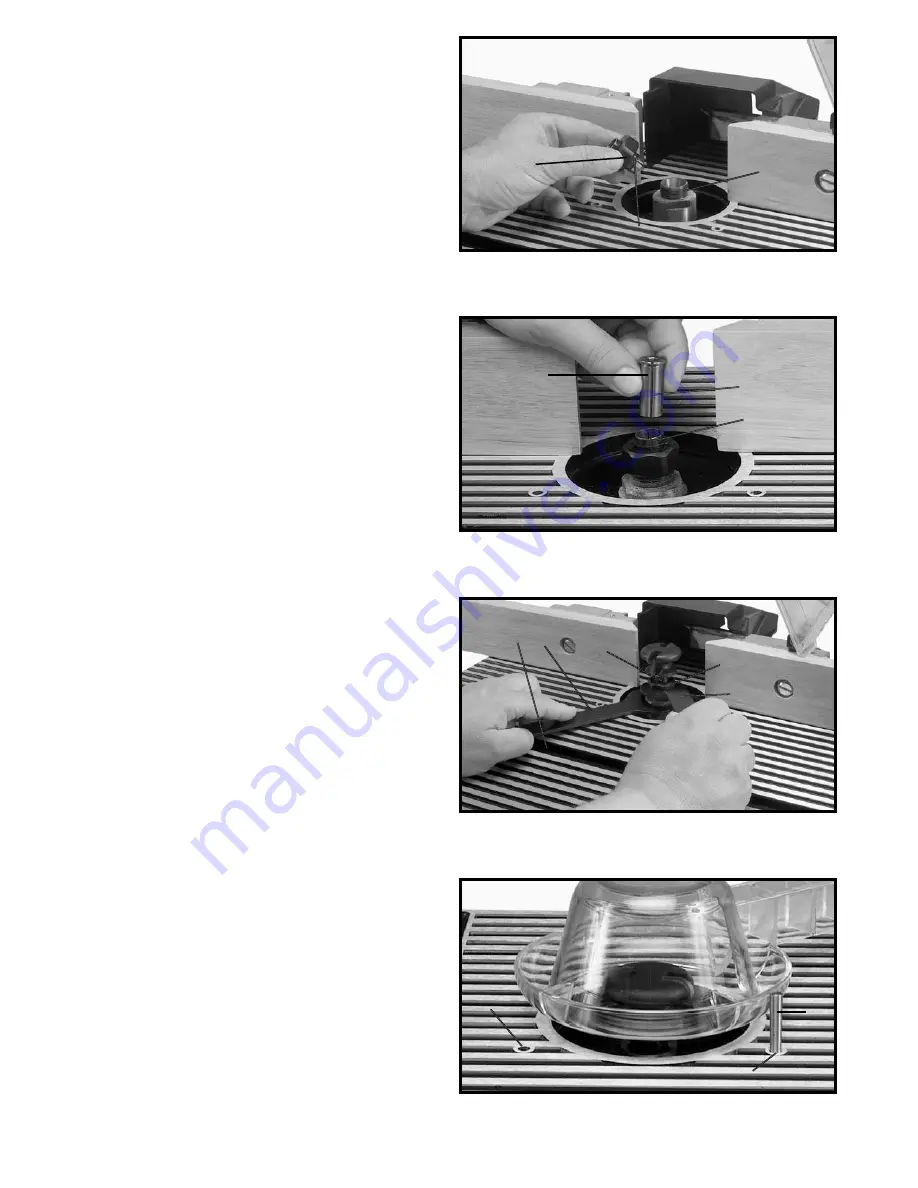

INSTALLING ROUTER BITS

1.

DISCONNECT MACHINE FROM POWER SOURCE.

2.

Raise spindle to the maximum height and tighten

lock knob.

3.

This machine is supplied with a 1/2 inch collet (A)

Fig. 27, that accepts 1/2 inch shank router bits. A 1/4

inch adapter sleeve (B) Fig. 28, is also furnished that

allows you to use 1/4 inch shank router bits.

4.

Insert 1/2 inch collet (A) Fig. 27, into spindle

assembly (C) and hand tighten nut (D). If you are using

1/4 inch shank router bits, insert 1/4 inch adapter sleeve

(B) Fig. 28, into 1/2 inch collet (A), making certain slot (K)

in adapter sleeve (B) is aligned with the slot in 1/2 inch

collet (A).

NOTE:

This is important for maximum

clamping of the router bit in the spindle.

5.

Clean and insert shank of router bit (E) Fig. 29, into

collet (A) or adapter sleeve until it bottoms, then back

out router bit approximately 1/16 inch.

6.

Place wrench (F) Fig. 29, on flats of spindle

assembly to keep spindle from turning during router bit

installation.

NOTE:

Spindle wrench (F) Fig. 29, features a round

protrusion on one side that makes installation easier.

With the open end of wrench (F) Fig. 29, on the flats of

the spindle, rotate the wrench until the protrusion slides

into the miter gage slot (G) as shown. Place the other

wrench (H) on flats of the collet and turn wrench

clockwise to tighten router bit in spindle assembly.

CAUTION: Table ridges may be sharp. To avoid

personal injury, we suggest that wrenches (F) and (H)

supplied with your machine be used when installing

and removing router bits.

Fig. 27

Fig. 28

Fig. 29

Fig. 30

STARTING PIN

A starting pin (A) Fig. 30, is supplied with your

Router/Shaper and is used to support the workpiece at

the start of the cut when using the Router/Shaper

without the fence. The starting pin can be inserted into

either one of the two holes (B) provided in the table.

A

D

C

H

E

F

G

A

B

B

A

A

K

B

Summary of Contents for 43-505

Page 17: ...17 NOTES...

Page 18: ...18 NOTES...