10

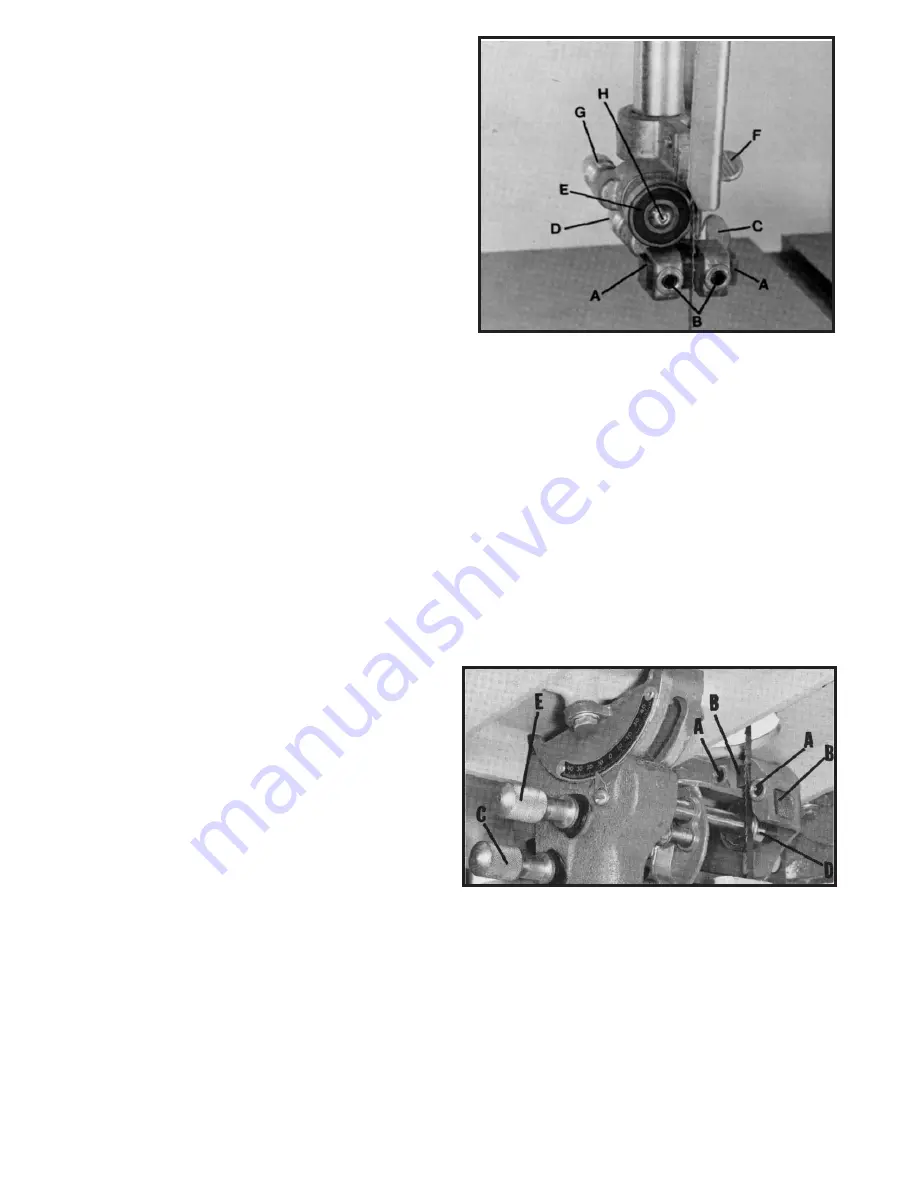

ADJUSTING UPPER BLADE GUIDES

AND BLADE SUPPORT BEARING

The upper blade guides and blade support bearings are ad-

justed only after the blade is tensioned and tracking properly.

To adjust proceed as follows:

1. The upper blade guides (A) Fig. 23, are held in place by

means of the set screws (B). Loosen the set screws (B) to

move the guides (A) as close as possible to the side of the

blade, being careful not to pinch the blade. Then tighten the

screws (B).

2. The guides (A) Fig. 23, should then be adjusted so that the

front edge of the guides are just behind the “gullets” of the saw

teeth. The complete guide block bracket can be moved in or

out by loosening thumb screw (C) and turning knurled knob (D)

Fig. 23. When guides (A) are set properly, tighten thumb

screw (C).

3. The upper blade support bearing (E) Fig. 23, prevents the

blade from being pushed too far to the back which could

damage the set in the saw teeth. The support bearing (E)

should be set 1/64 behind the blade by loosening thumb

screw (F) and turning knurled knob (G) to move the support

bearing (E) in or out.

4. The blade support bearing (E) should also be adjusted so

the back edge of the blade overlaps the outside diameter of

the ball bearing by about 1/16 . The bearing (E) is set on an

eccentric and to change position remove screw (H) and bear-

ing (E) Fig. 23. Loosen thumb screw (F), back out screw (G)

and re-position shaft that bearing (E) is attached to.

ADJUSTING LOWER BLADE GUIDES

AND BLADE SUPPORT BEARING

The lower blade guides and blade support bearing should be

adjusted at the same time as the upper guides and bearing as

follows:

1. Loosen the two screws (A) Fig. 24, and move the guides (B)

as close as possible to the side of the blade, being careful not

to pinch the blade. Then tighten screws (A).

2. The front edge of the guide blocks (B) should be adjusted

so they are just behind the “gullets” of the saw teeth by turn-

ing the knurled knob (C) Fig. 24.

3. The lower blade support bearing (D) Fig. 24, should be

adjusted so it is about 1/64 behind the back of the blade by

turning the knurled knob (E).

Fig. 23

Fig. 24