Aligning the Video Monitor

4–11

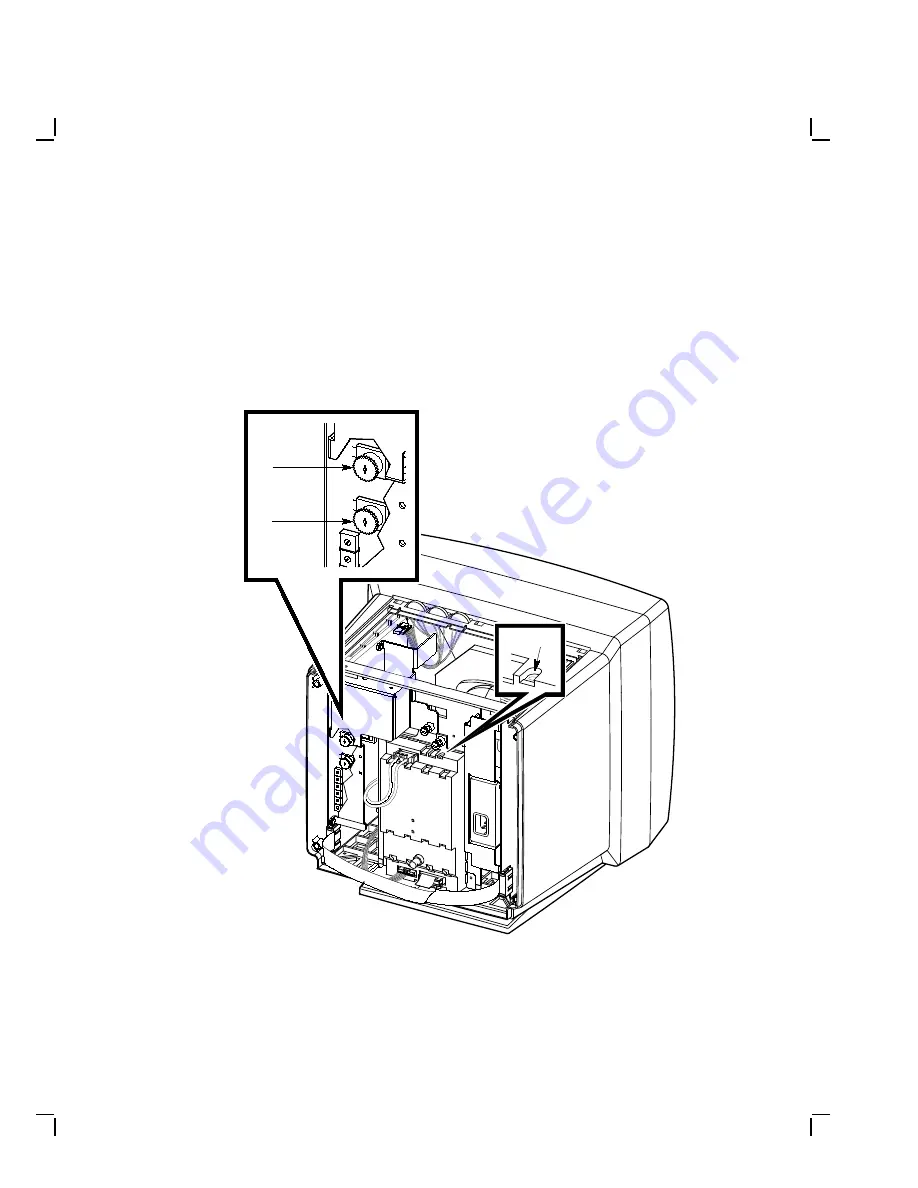

4.6 GAIN Adjustment

1.

Set the Contrast control to maximum and Brightness control for

background extinction.

2.

Set GAIN using the All-White pattern to obtain 0.283 luminance at

the screen center.

G2

MA-0300-90.DG

G4

G a i n

Figure 4–7

GAIN, G2, and FOCUS (G4) Adjustments