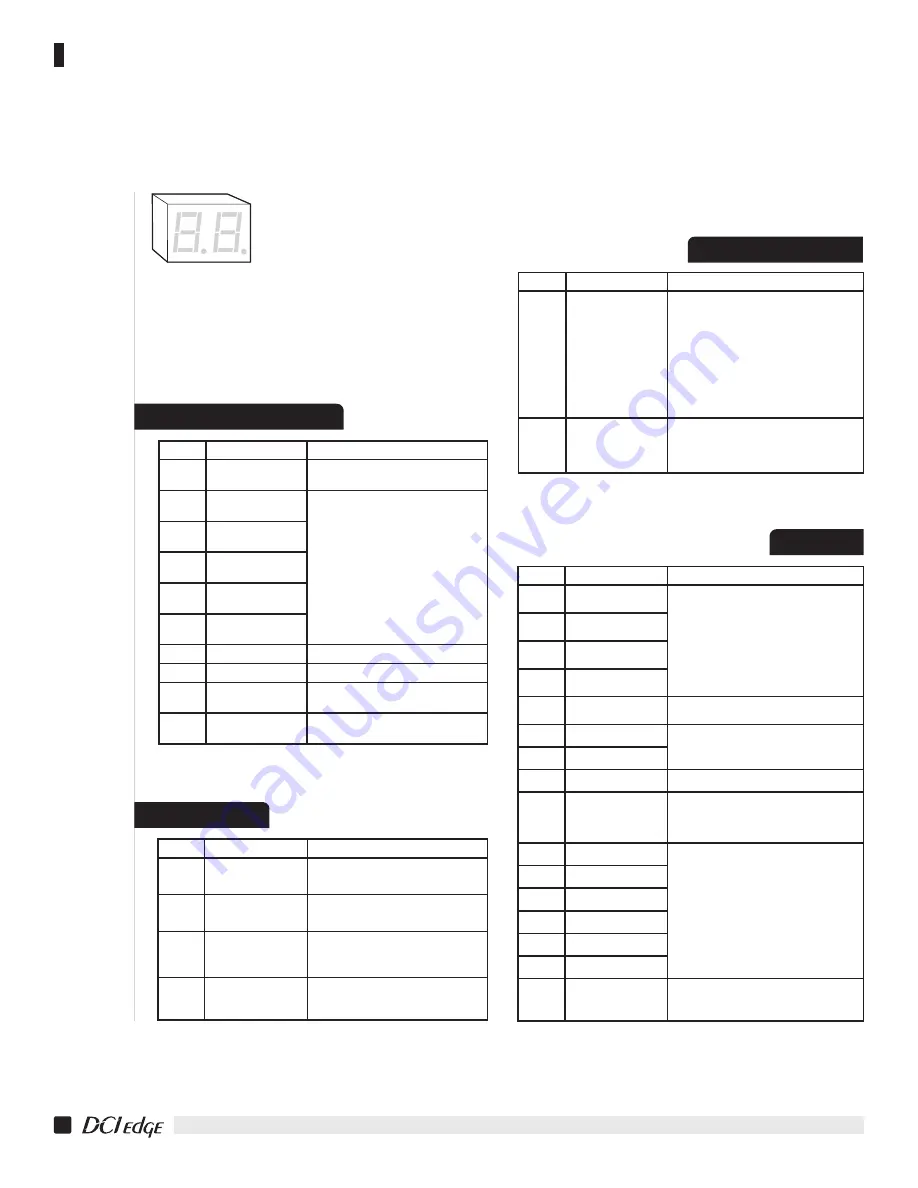

DIAGNOSTIC STATUS CODES

Status Codes are displayed on a two 7-segment display on

the chair control circuit board. These are visible through the

clear window of the protective cover. Errors are designated

with an 8 as the first digit. While there are error codes

displayed, no other status code will be displayed. When

more than one code’s condition is present, each applicable

code will will be displayed, alternating every second.

12

SERIES 4 DENTAL CHAIR

Installation Instructions

Display

Status

If this status is incorrect

00

System Normal, No

current action

Check Green LEDs are lit on the keypad

input board

10

Keypad connected to

KEY1 is being pressed

1. Check keypad for a stuck key

2. Check keypad cables for damage creating

a short circuit

11

Keypad connected to

KEY2 is being pressed

12

Keypad connected to

KEY3 is being pressed

13

Keypad connected to

KEY4 is being pressed

14

No motion in progress

while keypad is pressed

15

Backrest in motion

(normal function)

16

Base in motion

(normal function)

17

Auto-position in

progress

(normal function)

18

Auto-position in

progress

(normal function)

Display

Status

If this status is incorrect

20

Signal received to move

backrest but it has

reached its soft limit

Reprogram soft limits

21

Signal received to move

base but it has reached

its soft limit

Reprogram soft limits

22

Signal received to move

both base and backrest

but both have reached

their soft limits

Reprogram soft limits

25

Lamp is being activated

or deactivated

1. Check keypad for a stuck key

2. Check keypad cables for damage creating

a short circuit

POSITION CONTROLS

Display

Status

If this status is incorrect

30

Safety cover switch

engaged

1. Check the safety cover and ensure that it is free

to move up and down

2. Check that the safety cover properly activates

the switch

3. Check cable connections to the safety switches

attached to each side of the truss casting

4. Check cables connecting the switches for

continuity

5. Check that safety switches open the electrical

circuit when the lever is depressed

31

Auxiliary Switch engaged

1. Check the air switch in the delivery head for

proper function

2. Check keypad cable connecting the delivery

head Input Board to the Control Board

Display

Status

If this status is incorrect

80

Backrest Position value

too low

1. Check soft limits, reprogram as necessary

2. Check for damaged sensor cables

3. Check to ensure the sensor is installed with the

text on the box being right side up

81

Backrest Position value

too high

82

Base Position value

too low

83

Base Position value

too high

84

Software fault, watchdog

engaged

Replace Control Board if persistent

85

Base Sensor not found

1. Ensure that the sensor is connected to the

Control Board

2. Check sensor or input wiring for damage

86

Back Sensor not found

88

Harware fault

Replace Control Board if persistent

89

No keypads found

1. Check keypad connections both at the Control

Board and the Input Board to which the keypad

is connected

2. Check for damage to the keypad cables

F0

Fault on Base Port

Check sensor or input wiring for damage

F1

Fault on Base Port

F2

Fault on KEY1 Port

F3

Fault on KEY2 Port

F4

Fault on KEY3 Port

F5

Fault on KEY4 Port

Pu

Pump has overrun, chair

has been automatically

stoped

1. If chair had reached its mechanical limit, adjust

soft limits farther away from the mechanical limit

2. Check hydraulic system for leaks

SAFETY SWITCHES

ERRORS

INDICATORS